E2FM

Inductive proximity sensor in cylindrical full metal housing (case + sensing face)

The high durability stainless steel sensing face provides more than 20 times longer protection against mechanical damage than conventional sensors. The high mineral oil and coolant resistance and the immunity against small metal chips on the surface make this sensor ideal for metal cutting or drilling applications.

- Full body stainless steel housing for highest mechanical protection

- Low frequency modulation for metal chip immunity

- Flame retardant cable for high protection against welding spatter damage (pigtail models)

How can we help you?

If you have a question or would like to ask for a quote, please contact us or send a request.

Contact me E2FM

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for E2FM

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadSpecifications & ordering info

| Product | Size | Mounting type | Sensing distance | Output type | Operation mode | Connection method | Material housing | Cable specifications | Cable length | Overall length of sensor | Thread length | Features | Polarity | Degree of protection (IP) | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

M30 | Flush | 10 mm | 2-wire | NO | Cable | Stainless steel | PVC | 2 m | 64 mm | 43 mm | Fluoroplastic coating, Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M30, shielded, 10 mm, DC, 2-wire, NO, 2 m cable |

|

|

|

M30 | Flush | 10 mm | 2-wire | NO | M12 pigtail connector | Stainless steel | PVC | 0.3 m | 64 mm | 43 mm | Fluoroplastic coating, Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M30, shielded, 10mm, DC, 2-wire, NO, M12 with 0.3 m pigtail |

|

|

|

M30 | Flush | 10 mm | 2-wire | NO | M12 pigtail connector | Stainless steel | PVC | 0.3 m | 64 mm | 43 mm | Fluoroplastic coating, Metal sensing face | No | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M30, shielded, 10mm, DC, 2-wire, NO, M12 with 0.3m pigtail (no polarity) |

|

|

|

M8 | Flush | 1.5 mm | 2-wire | NO | Cable | Stainless steel | PVC | 2 m | 49 mm | 25 mm | Fluoroplastic coating, Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M8, shielded, 1.5 mm, DC, 2-wire, NO, cable 2 m |

|

|

|

M8 | Flush | 1.5 mm | 2-wire | NO | M12 pigtail connector | Stainless steel | PVC | 0.3 m | 49 mm | 25 mm | Fluoroplastic coating, Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M8, shielded, 1.5 mm, DC, 2-wire, NO, M12 with 0.3 m pigtail |

|

|

|

M12 | Flush | 2 mm | 2-wire | NO | Cable | Stainless steel | PVC | 2 m | 53 mm | 33 mm | Fluoroplastic coating, Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M12, shielded, 2 mm, DC, 2-wire, NO, 2 m prewired |

|

|

|

M12 | Flush | 2 mm | 2-wire | NO | M12 pigtail connector | Stainless steel | PVC | 0.3 m | 53 mm | 33 mm | Fluoroplastic coating, Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M12, shielded, 2 mm, DC, 2-wire, NO, 0.3 m cable with M12 connector |

|

|

|

M12 | Flush | 2 mm | 2-wire | NO | M12 pigtail connector | Stainless steel | PVC | 0.3 m | 53 mm | 33 mm | Fluoroplastic coating, Metal sensing face | No | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M12, shielded, 2 mm, DC, 2-wire, NO, No polarity, 0.3 m cable with M12 connector |

|

|

|

M18 | Flush | 5 mm | 2-wire | NO | Cable | Stainless steel | PVC | 2 m | 56 mm | 36 mm | Fluoroplastic coating, Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M18, shielded, 2 mm, DC, 2-wire, NO, 2 m prewired |

|

|

|

M18 | Flush | 5 mm | 2-wire | NO | M12 pigtail connector | Stainless steel | PVC | 0.3 m | 56 mm | 36 mm | Fluoroplastic coating, Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M18, shielded, 5 mm, DC, 2-wire, NO, M12 with 0.3 m cable |

|

|

|

M18 | Flush | 5 mm | 2-wire | NO | M12 pigtail connector | Stainless steel | PVC | 0.3 m | 56 mm | 36 mm | Fluoroplastic coating, Metal sensing face | No | IP67 | Proximity sensor, inductive, stainless steel face & body, fluororesin coated, long body, M18, shielded, 5 mm, DC, 2-wire, NO, M12 with 0.3 m cablel (no polarity) |

|

|

|

M30 | Flush | 10 mm | PNP | NO | Cable | Stainless steel | PVC | 2 m | 64 mm | 43 mm | Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, long body, M30, shielded, 10mm, DC, 3-wire, PNP-NO, 2 m cable |

|

|

|

M30 | Flush | 10 mm | PNP | NO | Connector M12 | Stainless steel | - | 64 mm | 43 mm | Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, long body, M30, shielded, 10mm, DC, 3-wire, PNP-NO, M12 plug-in |

|

|

|

|

M30 | Flush | 10 mm | PNP | NC | Cable | Stainless steel | PVC | 2 m | 64 mm | 43 mm | Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, long body, M30, shielded, 10mm, DC, 3-wire, PNP-NC, 2m cable |

|

|

|

M30 | Flush | 10 mm | NPN | NO | Cable | Stainless steel | PVC | 2 m | 64 mm | 43 mm | Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, long body, M30, shielded, 10mm, DC, 3-wire, NPN-NO, 2 m cable |

|

|

|

M30 | Flush | 10 mm | NPN | NO | Connector M12 | Stainless steel | - | 64 mm | 43 mm | Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, long body, M30, shielded, 10mm, DC, 3-wire, NPN-NO, M12 plug-in |

|

|

|

|

M30 | Flush | 10 mm | 2-wire | NO | Cable | Stainless steel | PVC | 2 m | 64 mm | 43 mm | Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, long body, M30, shielded, 10 mm, DC, 2-wire, NO, 2 m cable |

|

|

|

M30 | Flush | 10 mm | 2-wire | NO | M12 pigtail Smartclick connector | Stainless steel | PVC | 0.3 m | 64 mm | 43 mm | Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, long body, M30, shielded, 10mm, DC, 2-wire, NO, M12 with 0.3 m pigtail |

|

|

|

M30 | Flush | 10 mm | 2-wire | NO | M12 pigtail Smartclick connector | Stainless steel | PVC | 0.3 m | 64 mm | 43 mm | Metal sensing face | No | IP67 | Proximity sensor, inductive, stainless steel face & body, long body, M30, shielded, 10mm, DC, 2-wire, NO, M12 with 0.3m pigtail (no polarity) |

|

|

|

M8 | Flush | 1.5 mm | PNP | NO | Cable | Stainless steel | PVC | 2 m | 49 mm | 25 mm | Metal sensing face | Yes | IP67 | Proximity sensor, inductive, stainless steel face & body, long body, M8, shielded, 1.5mm, DC, 3-wire, PNP-NO, 2 m cable |

|

Features

Full metal face

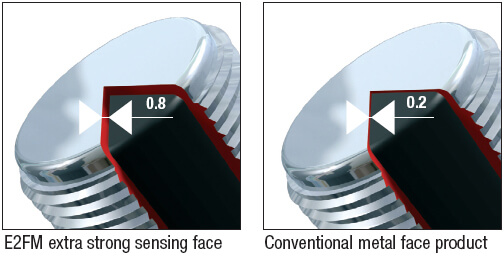

E2FM extra strong sensing face

Tested durability

Tested durability with more than 20 times longer lifetime compared to conventional metal face inductive sensors.

Metal chip immune

No interference by small metal chips on sensing surface

Welding spatter immune

Cable resistant to welding spatter

Performance comparison

Mechanical protection

Body – mechanical protection

| Issue: The body of a sensor may be damaged if too high torque is applied to mounting nuts or from accidental mechanical damage and can result in water entry (via cracks or microcracks) or complete product breakage. |

| Solutions: |

| * Market standard: basic protection for IP67 under normal handling conditions |

| ** Tested vibration and mechanical shock resistance and enhanced IP69k protection with our E2A in conditions with occasional higher vibrations, rough handling or cleaning |

| *** Additional tests with our special E2A under more demanding conditions with frequent vibrations, rough handling and frequent water sprays or cleaning |

Sensing face – mechanical robustness

| Issue: Sensing face damages can be caused by object impacts or frequent brushing. The results can be functional damage, sensing distance change or water entry. |

| Solutions: |

| * Market standard: basic mechanical protection for normal handling operations |

| ** Tested enhanced robustness for our E2A line for occasional stronger impacts |

| *** Highest robustness with the E2FM steel sensing face for frequent heavy impacts |

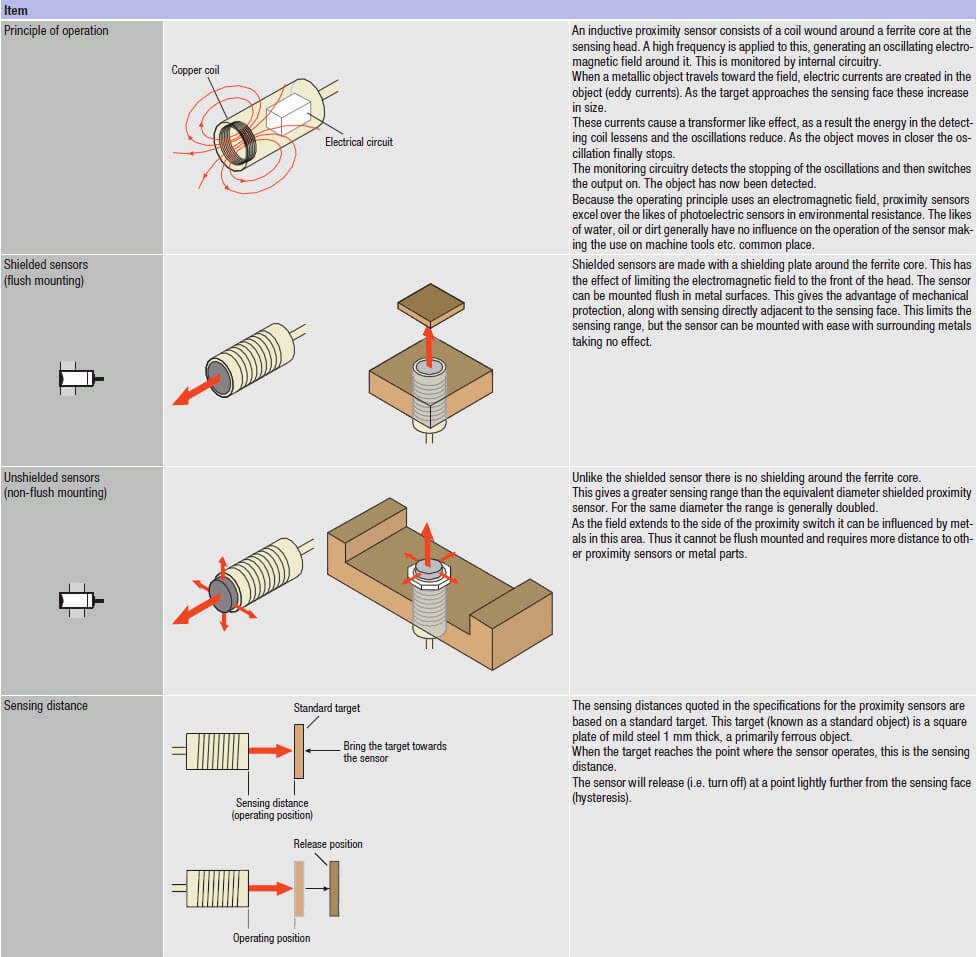

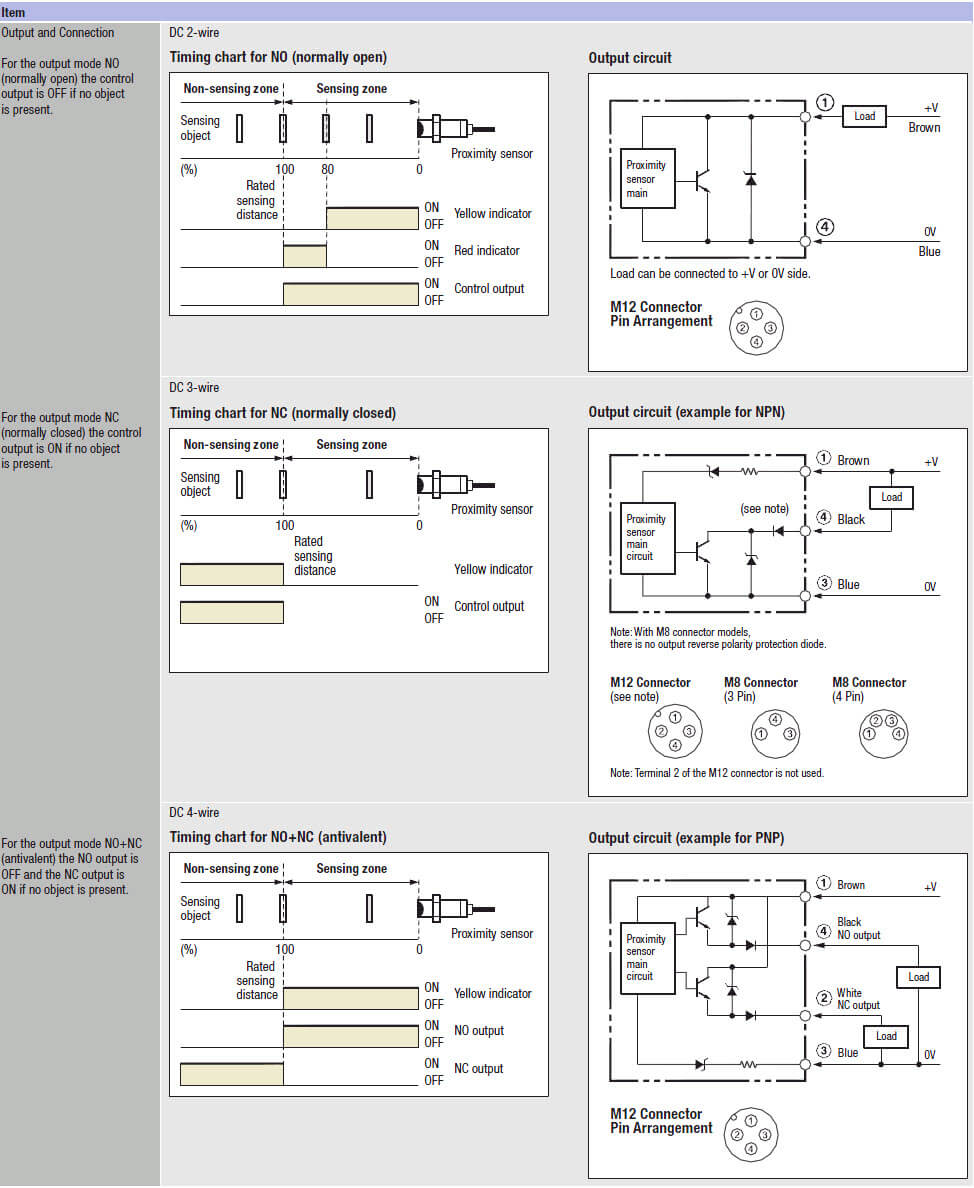

Technical information

xd_e2fm-(q)xd_instruction_sheet_en.jpg)