E2E NEXT

Proximity Sensor E2E NEXT

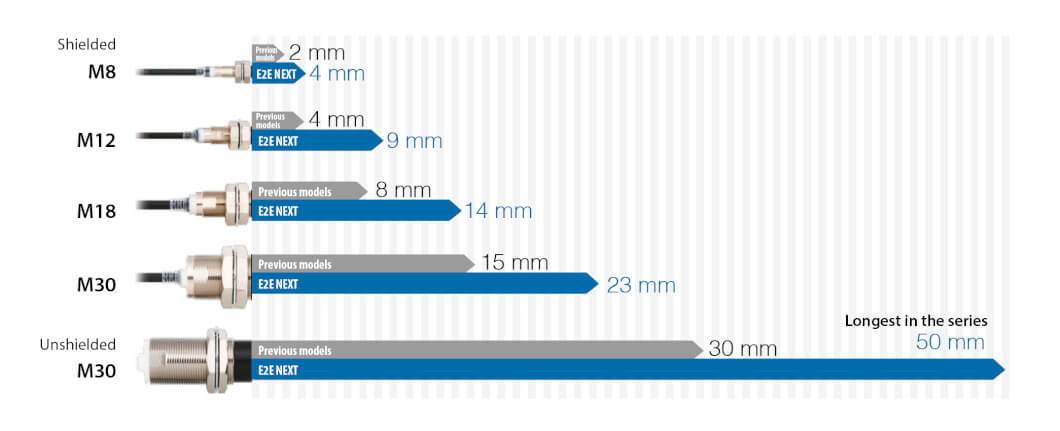

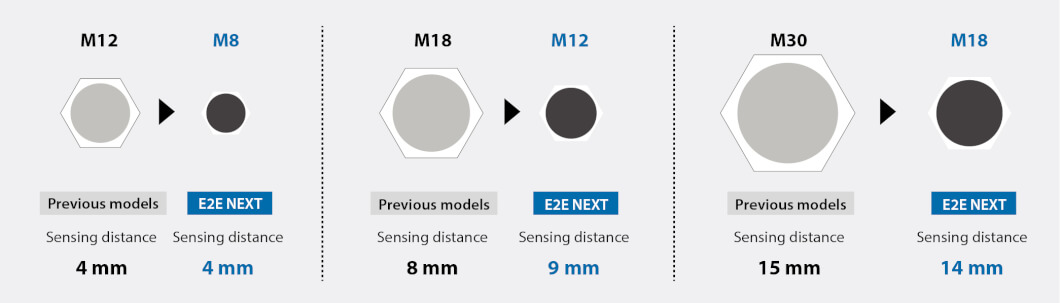

Long-distance detection prevents unexpected facility stoppages

- The world's longest sensing distance

- With high-brightness LED, the indicator is visible anywhere from 360°.

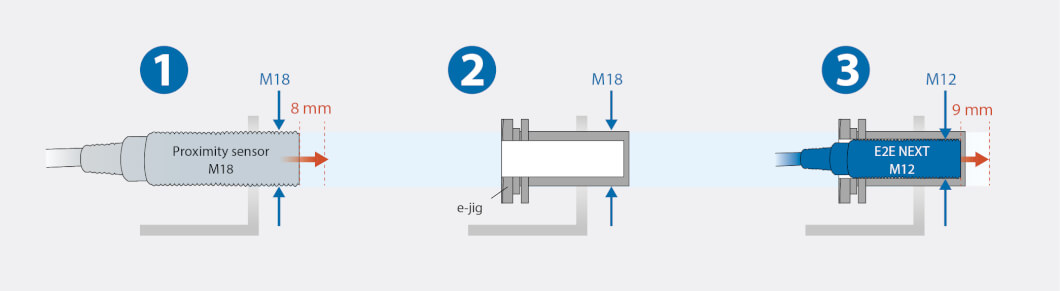

- Only 10 Seconds to Replace a Proximity Sensor with the "e-jig" (Mounting Sleeve).

- Cables with enhanced oil resistance enabled 2-year oil resistance

- IP69K compliant for water resistance and wash resistance

- Comes in a wide variation to make sensor selection easy

- UL and CSA certification

Specifications & ordering info

| Product | Size | Mounting type | Sensing distance | Output type | Operation mode | Connection method | Material housing | Cable specifications | Cable length | IO-Link baud rate | Overall length of sensor | Thread length | Features | Degree of protection (IP) | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

M30 | Flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 10 m | COM3 (230.4 kbps) | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 10 m cable |

|

|

|

|

M30 | Flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M30 | Flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m cable |

|

|

|

|

M30 | Flush | 10 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M30 | Flush | 10 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M30 | Flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 60.3 mm | 39 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass short body, M30, shielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m robotic cable |

|

|

|

M30 | Flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass long body, M30, shielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m prewired |

|

|

|

|

M30 | Flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m prewired |

|

|

|

|

M30 | Flush | 10 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 80 mm | 65 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass long body, M30, shielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M30 | Flush | 10 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M30 | Flush | 10 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, PNP NC, 5 m cable |

|

|

|

|

M30 | Flush | 10 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M30 | Flush | 10 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 10 mm, DC, 3-wire, PNP NC, 2 m prewired |

|

|

|

|

M30 | Flush | 10 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 80 mm | 65 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 10 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M30 | Flush | 10 mm | IO-Link, PNP | NO + NC | Connector M12 | Brass, nickel plated | - | COM2 (38.4 kbps) | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 4-wire, PNP NO+NC, IO-Link COM2, M12 connector |

|

||

|

|

M30 | Flush | 10 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M30 | Flush | 10 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, NPN NO, 5 m cable |

|

|

|

|

M30 | Flush | 10 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M30 | Flush | 10 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 60.3 mm | 39 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, NPN NO, 2 m robotic cable |

|

|

|

M30 | Flush | 10 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 10 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M30 | Flush | 10 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 10 mm, DC, 3-wire, NPN NO, 5 m cable |

|

|

|

|

M30 | Flush | 10 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 80 mm | 65 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 10 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M30 | Flush | 10 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M30 | Flush | 10 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, NPN NC, 5 m cable |

|

|

|

|

M30 | Flush | 10 mm | NPN | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 3-wire, NPN NC, M12 connector |

|

||

|

|

M30 | Flush | 10 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 10 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M30 | Flush | 10 mm | NPN | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 80 mm | 65 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 10 mm, DC, 3-wire, NPN NC, M12 connector |

|

||

|

|

M30 | Flush | 10 mm | NPN | NO + NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 10 mm, DC, 4-wire, NPN NO+NC, M12 connector |

|

||

|

|

M12 | Non-flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M12 | Non-flush | 10 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 48 mm | 26 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M12 | Non-flush | 10 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M12 | Non-flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 47.1 mm | 26 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m robotic cable |

|

|

|

M18 | Non-flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 10 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

|

|

|

M18 | Non-flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 53 mm | 28 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M18 | Non-flush | 10 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Non-flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 55.3 mm | 28 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass short body, M18, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m robotic cable |

|

|

|

M12 | Non-flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 69.1 mm | 48 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M12 | Non-flush | 10 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 70 mm | 48 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M12 | Non-flush | 10 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 69.1 mm | 48 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Non-flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 75 mm | 50 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass long body, M18, unshielded, 10 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M12 | Non-flush | 10 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 10 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M12 | Non-flush | 10 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 48 mm | 26 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 10 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M18 | Non-flush | 10 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, PNP NC, 5 m prewired |

|

|

|

|

M18 | Non-flush | 10 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 28 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M12 | Non-flush | 10 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 69.1 mm | 48 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 10 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M12 | Non-flush | 10 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 70 mm | 48 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 10 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M18 | Non-flush | 10 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 10 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 75 mm | 50 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 10 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M12 | Non-flush | 10 mm | IO-Link, PNP | NO + NC | Connector M12 | Brass, nickel plated | - | COM2 (38.4 kbps) | 48 mm | 26 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 10 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, M12 connector |

|

||

|

|

M12 | Non-flush | 10 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 48 mm | 26 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 10 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M18 | Non-flush | 10 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, NPN NO, 5 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 28 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M18 | Non-flush | 10 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 28 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, NPN NO, 2 m robotic cable |

|

|

|

M18 | Non-flush | 10 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 10 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 10 mm, DC, 3-wire, NPN NO, 5 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 75 mm | 50 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 10 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M18 | Non-flush | 10 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, NPN NC, 5 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | NPN | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 28 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 10 mm, DC, 3-wire, NPN NC, M12 connector |

|

||

|

|

M18 | Non-flush | 10 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 10 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 10 mm | NPN | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 75 mm | 50 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 10 mm, DC, 3-wire, NPN NC, M12 connector |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NO, 2 m cable, DC 2-wire |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NO, 5 m cable, DC 2-wire |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NO, 0.3 m pig-tail, DC 2-wire |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NO, 0.3 m pig-tail, DC 2-wire, no polarity |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 47.1 mm | 26 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NO, 2 m cable robotic, DC 2-wire |

|

|

|

|

M12 | Non-flush | 10 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 47.1 mm | 26 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NO, 5 m cable robotic, DC 2-wire |

|

|

|

|

M12 | Non-flush | 10 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NO, 2 m cable, DC 2-wire, no polarity |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NO, 5 m cable, DC 2-wire, no polarity |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 47.1 mm | 26 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NO, 2 m cable robotic, DC 2-wire, no polarity |

|

|

|

|

M12 | Non-flush | 10 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 47.1 mm | 26 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NO, 5 m cable robotic, DC 2-wire, no polarity |

|

|

|

|

M12 | Non-flush | 10 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NC, 2 m cable, DC 2-wire |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NC, 5 m cable, DC 2-wire |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NC | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NC, 0.3 m pig-tail, DC 2-wire |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NC | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NC, 0.3 m pig-tail, DC 2-wire, no polarity |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 47.1 mm | 26 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NC, 2 m cable robotic, DC 2-wire |

|

|

|

|

M12 | Non-flush | 10 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 47.1 mm | 26 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NC, 5 m cable robotic, DC 2-wire |

|

|

|

|

M12 | Non-flush | 10 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NC, 2 m cable, DC 2-wire, no polarity |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NC, 5 m cable, DC 2-wire, no polarity |

|

||

|

|

M12 | Non-flush | 10 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 47.1 mm | 26 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NC, 2 m cable robotic, DC 2-wire, no polarity |

|

|

|

|

M12 | Non-flush | 10 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 47.1 mm | 26 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M12, non-shielded, 10 mm, NC, 5 m cable robotic, DC 2-wire, no polarity |

|

|

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NO, 2 m cable, DC 2-wire |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NO, 5 m cable, DC 2-wire |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NO, 0.3 m pig-tail, DC 2-wire |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NO, 0.3 m pig-tail, DC 2-wire, no polarity |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NO, 2 m cable robotic, DC 2-wire |

|

|

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NO, 5 m cable robotic, DC 2-wire |

|

|

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NO, 2 m cable, DC 2-wire, no polarity |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NO, 5 m cable, DC 2-wire, no polarity |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NO, 2 m cable robotic, DC 2-wire, no polarity |

|

|

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NO, 5 m cable robotic, DC 2-wire, no polarity |

|

|

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NC, 2 m cable, DC 2-wire |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NC, 5 m cable, DC 2-wire |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NC | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NC, 0.3 m pig-tail, DC 2-wire |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NC | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NC, 0.3 m pig-tail, DC 2-wire, no polarity |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NC, 2 m cable robotic, DC 2-wire |

|

|

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NC, 5 m cable robotic, DC 2-wire |

|

|

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NC, 2 m cable, DC 2-wire, no polarity |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NC, 5 m cable, DC 2-wire, no polarity |

|

||

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NC, 2 m cable robotic, DC 2-wire, no polarity |

|

|

|

|

M18 | Quasi-flush | 11 mm | 2-wire | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, brass-nickel, M18, shielded, 11 mm, NC, 5 m cable robotic, DC 2-wire, no polarity |

|

|

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m prewired |

|

|

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 53 mm | 33 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m robotic cable |

|

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 77.3 mm | 59 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 12 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 75 mm | 59 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 12 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 77.3 mm | 59 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 12 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Quasi-flush | 12 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 12 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NC, 5 m prewired |

|

|

|

|

M18 | Quasi-flush | 12 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 33 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M18 | Quasi-flush | 12 mm | PNP | NC | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | Not Applicable | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NC, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Quasi-flush | 12 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 77.3 mm | 59 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 12 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 12 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 75 mm | 59 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 12 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM2 (38.4 kbps) | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO + NC | Connector M12 | Brass, nickel plated | - | COM2 (38.4 kbps) | 53 mm | 33 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, M12 connector |

|

||

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO + NC | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM2 (38.4 kbps) | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM2 (38.4 kbps) | 77.3 mm | 59 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 12 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 12 mm | IO-Link, PNP | NO + NC | Connector M12 | Brass, nickel plated | - | COM2 (38.4 kbps) | 75 mm | 59 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 12 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, M12 connector |

|

||

|

|

M18 | Quasi-flush | 12 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 12 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 33 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M18 | Quasi-flush | 12 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 12 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, NPN NC, 5 m prewired |

|

|

|

|

M18 | Quasi-flush | 12 mm | NPN | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 33 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 12 mm, DC, 3-wire, NPN NC, M12 connector |

|

||

|

|

M18 | Quasi-flush | 14 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 14 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 53 mm | 33 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M18 | Quasi-flush | 14 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Quasi-flush | 14 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m robotic cable |

|

|

|

M18 | Quasi-flush | 14 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 55.3 mm | 33 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m robotic cable |

|

|

|

M18 | Quasi-flush | 14 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 77.3 mm | 59 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 14 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 14 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 75 mm | 59 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 14 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M18 | Quasi-flush | 14 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 77.3 mm | 59 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 14 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Quasi-flush | 14 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 14 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 33 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M18 | Quasi-flush | 14 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 77.3 mm | 59 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 14 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 14 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 75 mm | 59 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 14 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M18 | Flush | 14 mm | NPN | NO | Cable | Brass, nickel plated | PVC | 2 m | Not Applicable | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 14 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 33 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M18 | Flush | 14 mm | NPN | NO | Cable | Brass, nickel plated | PVC | 2 m | Not Applicable | 77.3 mm | 59 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 14 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 14 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 75 mm | 59 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 14 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M18 | Quasi-flush | 14 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M18 | Quasi-flush | 14 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 55.3 mm | 33 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, NPN NC, 5 m cable |

|

|

|

|

M18 | Quasi-flush | 14 mm | NPN | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 33 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, shielded, 14 mm, DC, 3-wire, NPN NC, M12 connector |

|

||

|

|

M18 | Flush | 14 mm | NPN | NC | Cable | Brass, nickel plated | PVC | 2 m | Not Applicable | 77.3 mm | 59 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, shielded, 14 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 10 m | COM3 (230.4 kbps) | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NO, IO-Link COM3, 10 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 60.3 mm | 39 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m robotic cable |

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 80 mm | 65 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M30 | Quasi-flush | 15 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 10 m | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NC, 10 m cable |

|

||

|

|

M30 | Quasi-flush | 15 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NC, 5 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, PNP NC, 5 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 80 mm | 65 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM2 (38.4 kbps) | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO + NC | Connector M12 | Brass, nickel plated | - | COM2 (38.4 kbps) | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO + NC | M12 pigtail Smartclick connector | Brass, nickel plated | PVC | 0.3 m | COM2 (38.4 kbps) | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM2 (38.4 kbps) | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM2 (38.4 kbps) | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, 5 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | IO-Link, PNP | NO + NC | Connector M12 | Brass, nickel plated | - | COM2 (38.4 kbps) | 80 mm | 65 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, NPN NO, 5 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, NPN NO, 5 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 80 mm | 65 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, NPN NC, 5 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | NPN | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, NPN NC, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, NPN NC, 5 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | NPN | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 80 mm | 65 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, NPN NC, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | NPN | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 60.3 mm | 39 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, NPN NO+NC, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | NPN | NO + NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 58 mm | 39 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, shielded, 15 mm, DC, 3-wire, NPN NO+NC, M12 connector |

|

||

|

|

M30 | Quasi-flush | 15 mm | NPN | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 82.3 mm | 65 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, NPN NO+NC, 2 m cable |

|

|

|

|

M30 | Quasi-flush | 15 mm | NPN | NO + NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 80 mm | 65 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, shielded, 15 mm, DC, 3-wire, NPN NO+NC, M12 connector |

|

||

|

|

M12 | Non-flush | 16 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M12 | Non-flush | 16 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 48 mm | 26 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M12 | Non-flush | 16 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M12 | Non-flush | 16 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 47.1 mm | 26 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m robotic cable |

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 10 m | COM3 (230.4 kbps) | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, 10 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 53 mm | 28 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 55.3 mm | 28 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m robotic cable |

|

|

|

M12 | Non-flush | 16 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 69.1 mm | 48 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M12 | Non-flush | 16 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 70 mm | 48 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M12 | Non-flush | 16 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 69.1 mm | 48 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 75 mm | 50 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M12 | Non-flush | 16 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 16 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M12 | Non-flush | 16 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 48 mm | 26 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 16 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M18 | Non-flush | 16 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NC, 5 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 28 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M12 | Non-flush | 16 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 69.1 mm | 48 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 16 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M12 | Non-flush | 16 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 70 mm | 48 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 16 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M18 | Non-flush | 16 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, PNP NC, 5 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 75 mm | 50 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM2 (38.4 kbps) | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO + NC | Connector M12 | Brass, nickel plated | - | COM2 (38.4 kbps) | 53 mm | 28 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, M12 connector |

|

||

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO + NC | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM2 (38.4 kbps) | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM2 (38.4 kbps) | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | IO-Link, PNP | NO + NC | Connector M12 | Brass, nickel plated | - | COM2 (38.4 kbps) | 75 mm | 50 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, PNP NO+NC, IO-Link COM2, M12 connector |

|

||

|

|

M12 | Non-flush | 16 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 48 mm | 26 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 16 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M18 | Non-flush | 16 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, NPN NO, 5 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 28 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M12 | Non-flush | 16 mm | NPN | NO | Cable | Brass, nickel plated | PVC | 2 m | Not Applicable | 69.1 mm | 48 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 16 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, NPN NO, 5 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NO | Connector M12 | Brass, nickel plated | - | Not Applicable | 75 mm | 50 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, NPN NO, M12 connector |

|

||

|

|

M12 | Non-flush | 16 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 47.1 mm | 26 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M12, unshielded, 16 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, NPN NC, 5 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 28 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, NPN NC, M12 connector |

|

||

|

|

M12 | Non-flush | 16 mm | NPN | NC | Cable | Brass, nickel plated | PVC | 2 m | Not Applicable | 69.1 mm | 48 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M12, unshielded, 16 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, NPN NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, NPN NC, 5 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 75 mm | 50 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, NPN NC, M12 connector |

|

||

|

|

M18 | Non-flush | 16 mm | NPN | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 55.3 mm | 28 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, NPN NO+NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NO + NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 53 mm | 28 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M18, unshielded, 16 mm, DC, 3-wire, NPN NO+NC, M12 connector |

|

||

|

|

M18 | Non-flush | 16 mm | NPN | NO + NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 77.3 mm | 50 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, NPN NO+NC, 2 m cable |

|

|

|

|

M18 | Non-flush | 16 mm | NPN | NO + NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 75 mm | 50 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M18, unshielded, 16 mm, DC, 3-wire, NPN NO+NC, M12 connector |

|

||

|

|

M30 | Non-flush | 18 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 60.3 mm | 30 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, unshielded, 18 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M30 | Non-flush | 18 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 60.3 mm | 30 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, unshielded, 18 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m cable |

|

|

|

|

M30 | Non-flush | 18 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 58 mm | 30 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, unshielded, 30 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M30 | Non-flush | 18 mm | IO-Link, PNP | NO | M12 pigtail Smartclick connector | Brass, nickel plated | PVC (oil-resistant) | 0.3 m | COM3 (230.4 kbps) | 60.3 mm | 30 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, unshielded, 18 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 pigtail Smartclick connector, 0.3 m |

|

|

|

|

M30 | Non-flush | 18 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 60.3 mm | 30 mm | Flexible cable | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, unshielded, 18 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m robotic cable |

|

|

|

M30 | Non-flush | 18 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | COM3 (230.4 kbps) | 82.3 mm | 52 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, unshielded, 18 mm, DC, 3-wire, PNP NO, IO-Link COM3, 2 m cable |

|

|

|

|

M30 | Non-flush | 18 mm | IO-Link, PNP | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | COM3 (230.4 kbps) | 82.3 mm | 52 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass long body, M30, unshielded, 18 mm, DC, 3-wire, PNP NO, IO-Link COM3, 5 m prewired |

|

|

|

|

M30 | Non-flush | 18 mm | IO-Link, PNP | NO | Connector M12 | Brass, nickel plated | - | COM3 (230.4 kbps) | 80 mm | 52 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass long body, M30, unshielded, 18 mm, DC, 3-wire, PNP NO, IO-Link COM3, M12 connector |

|

||

|

|

M30 | Non-flush | 18 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 60.3 mm | 30 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, unshielded, 18 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M30 | Non-flush | 18 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 5 m | Not Applicable | 60.3 mm | 30 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, unshielded, 18 mm, DC, 3-wire, PNP NC, 5 m cable |

|

|

|

|

M30 | Non-flush | 18 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 58 mm | 30 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, short body, M30, unshielded, 18 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M30 | Non-flush | 18 mm | PNP | NC | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 82.3 mm | 52 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, unshielded, 18 mm, DC, 3-wire, PNP NC, 2 m cable |

|

|

|

|

M30 | Non-flush | 18 mm | PNP | NC | Connector M12 | Brass, nickel plated | - | Not Applicable | 80 mm | 52 mm | IP67/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, unshielded, 18 mm, DC, 3-wire, PNP NC, M12 connector |

|

||

|

|

M30 | Non-flush | 18 mm | NPN | NO | Cable | Brass, nickel plated | PVC (oil-resistant) | 2 m | Not Applicable | 60.3 mm | 30 mm | IP67/IP67G/IP69K | Proximity sensor, inductive, nickel-brass, long body, M30, unshielded, 18 mm, DC, 3-wire, NPN NO, 2 m cable |

|

|

|

|