Industrial PC (IPC)

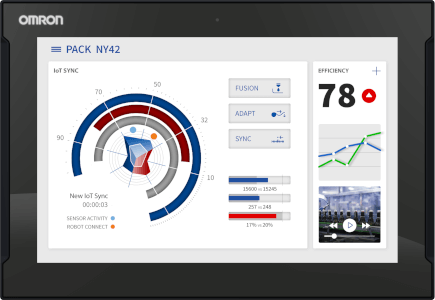

Industrial PCs (IPC) or Industrial Computers are designed to provide a powerful, reliable and scalable computing platform for industrial automation in harsh industrial environments.

Industrial PCs can control and monitor diverse industrial processes, enabling real-time data acquisition, analysis, and decision-making.

By leveraging the power of IPCs, manufacturers can optimize operational efficiency, boost productivity, and enhance overall reliability.

Want to know more about OMRON Industrial Computers?

| NYB | NYP | NYE Series | NY5 | NYM | |

|---|---|---|---|---|---|

|

|

|

|

|

|

| Industrial Box PC | Industrial Panel PC | Basic Industrial Panel PC | IPC Machine Controller | Industrial Monitor |

-

NYB

Industrial Box PC

-

NYP

Industrial Panel PC

-

NYE Series

Basic Industrial Panel PC

-

NY5

IPC Machine Controller

-

NYM

Industrial Monitor

Contact us

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact me Industrial PC

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for Industrial PC

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadTechnology

What is an industrial PC?

What does an industrial PC do?

An industrial PC, equipped with powerful processors, can perform various functions in industrial automation, such as:

Control and monitoring

Data acquisition and analysis

Human-Machine Interface (HMI)

Customization

Running Software

Industrial PC vs normal PC

What is the key difference between an Industrial PC and a normal PC for home use?

Compared to normal PCs, Industrial PCs must prioritize reliability and optimal performance to meet the demands of industrial applications. Industrial PCs are ruggedized systems designed to withstand harsh industrial environments. They typically come in robust enclosures that protect against dust, moisture, vibrations, and extreme temperatures. This contrasts to the normal home situation where a normal PC is used. To achieve these challenging demands, OMRON's industrial PCs eliminate unnecessary complexities. These computers are designed without internal cables and complex heatpipes, ensuring simplicity and efficiency. The structurally uniform mechanics enable scalability, reducing costs for future expansions. With a rock-solid architecture and a die-cast aluminum case, these industrial PCs offer durability and robustness while minimizing assembly, maintenance, and labor costs.

What are the advantages and disadvantages of industrial-grade computers?

- Robust and reliable, Industrial computers are rugged and Industrial computers are designed to withstand harsh environmental conditions prevalent in industrial settings.

- Scalable and easy-to customize, Industrial PCs support various expansion cards, interfaces, and peripherals.

- Industrial computer systems are compatible with industrial software, Industrial PCs are designed to be compatible with software applications such as SCADA systems, PLC programming tools, and other industry-specific software.

- Industrial PCs have longer product lifecycles and extended availability compared to commercial PCs.

- Ready for the IoT or industrial IoT (iIoT)

- Higher upfront costs compared to standard commercial PCs.

- Industrial PCs may require specialized knowledge and skills for maintenance and repairs

- In some cases, industrial PCs may be over-specified for certain applications

Fanless industrial pc vs industrial computers with a fan

Industrial panel pc: what’s the difference with a standard IPC?

When considering the use of industrial computing solutions, it is important to understand the differences between an industrial panel PC and a standard industrial PC. Here are three key differences:

Integrated display interface

Design and form factor

Environmental durability

Industrial Panel PCs are specifically designed to withstand harsh conditions, with rugged enclosures with high IP ratings to protect against dust, water and extreme temperatures. Standard industrial PCs, while durable, often lack the level of integration and protection offered by their panel counterparts.

Solutions

Our line of Industrial PC's

We offer a wide range of industrial computer solutions with a variety of configurations:

- Intel® 11th generation embedded CPU on board. Intel Xeon, Intel Core, Intel Celeron, or Intel Atom

- Fanless IPC's for passive cooling or computers with fans for active cooling

- Windows 10 IoT Enterprise

- RAM memory varying from 2GB to 16GB

- Different built-in ports like Displayport, Ethernet, USB 3.0, EtherCAT

- Storage on HDD or Solid-state drive (SSD)

- PCI Slot Expansion options

Industrial Box PC's

Industrial Panel PC's

Industrial Monitor

IPC vs PLC & HMI

The decision to select an industrial PC, PLC, or HMI depends on the specific requirements and objectives of the application. In some cases, a combination of these devices may be the ideal solution.

IPC

PLC

Human-Machine Interface (HMI)

Applications of Industrial computers

Artificial Intelligence: hope, hype and FOMO

Ten years ago when we received enquiries about AI-based projects, they were mainly driven by hype or FOMO. When I asked why they wanted to get into AI, the answer, more often than not, was either ‘because my boss asked me to’, ‘because we have a lot of data’ or ‘because it seems like an interesting area’. None of these were particularly solid reasons and certainly didn’t justify the hefty investment that AI applications would have required at that time.

That is changing, and hope, rather than hype or ‘FOMO’, is the driver. Customers don’t ask whether we can help them with AI anymore. They ask us whether we can help with predictive maintenance, quality control or process optimisation. They come to us with a problem that they want us to help solve. The adoption of AI is no longer a motive or an aim in itself. Instead, AI has become an ‘enabler’.

Whatever the industry - whether food & drink, pharmaceutical, electronics or automotive - the end goal is the same: producing high quality, defect-free products at a lower cost, using less energy and less labour. And AI can be one of a suite of solutions for achieving those objectives.

Real time data monitoring ensures defect-free relays

OMRON Automotive Electronics Italy has upgraded its production line of Power and G8HN relays for the automotive market.

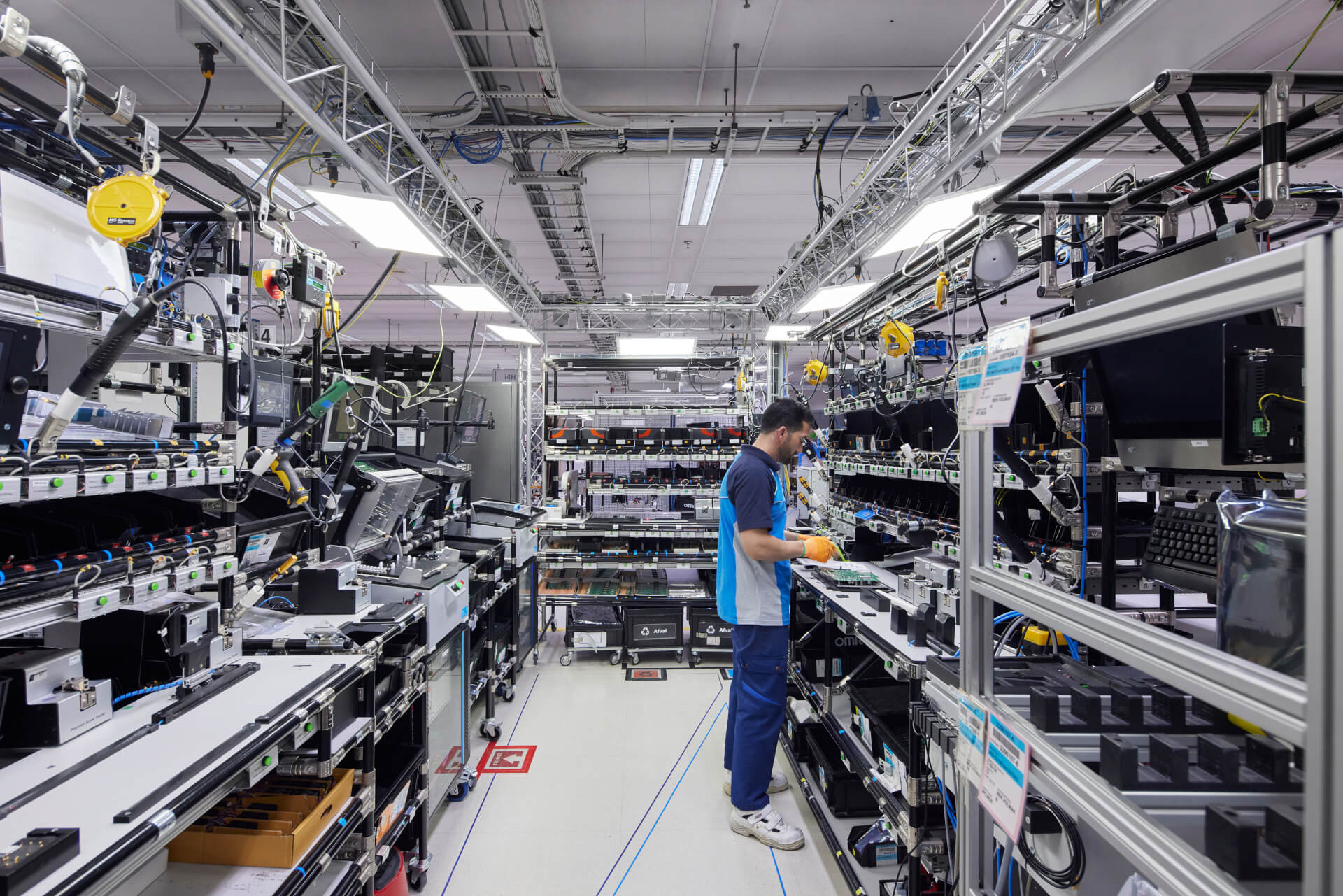

Building the Factory of the Future together

As one of the largest business units at OMRON, we aim to further develop the Den Bosch plant to serve the needs in the EMEA region.

We’re Here to Help

Got a question? Our specialists are ready to assist you every step of the way.

Contact me Industrial PC

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for Industrial PC

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download