Cobots (Collaborative Robots)

How can collaborative robots (cobots) improve industrial operations and enable human-robot collaboration to drive productivity and safety?

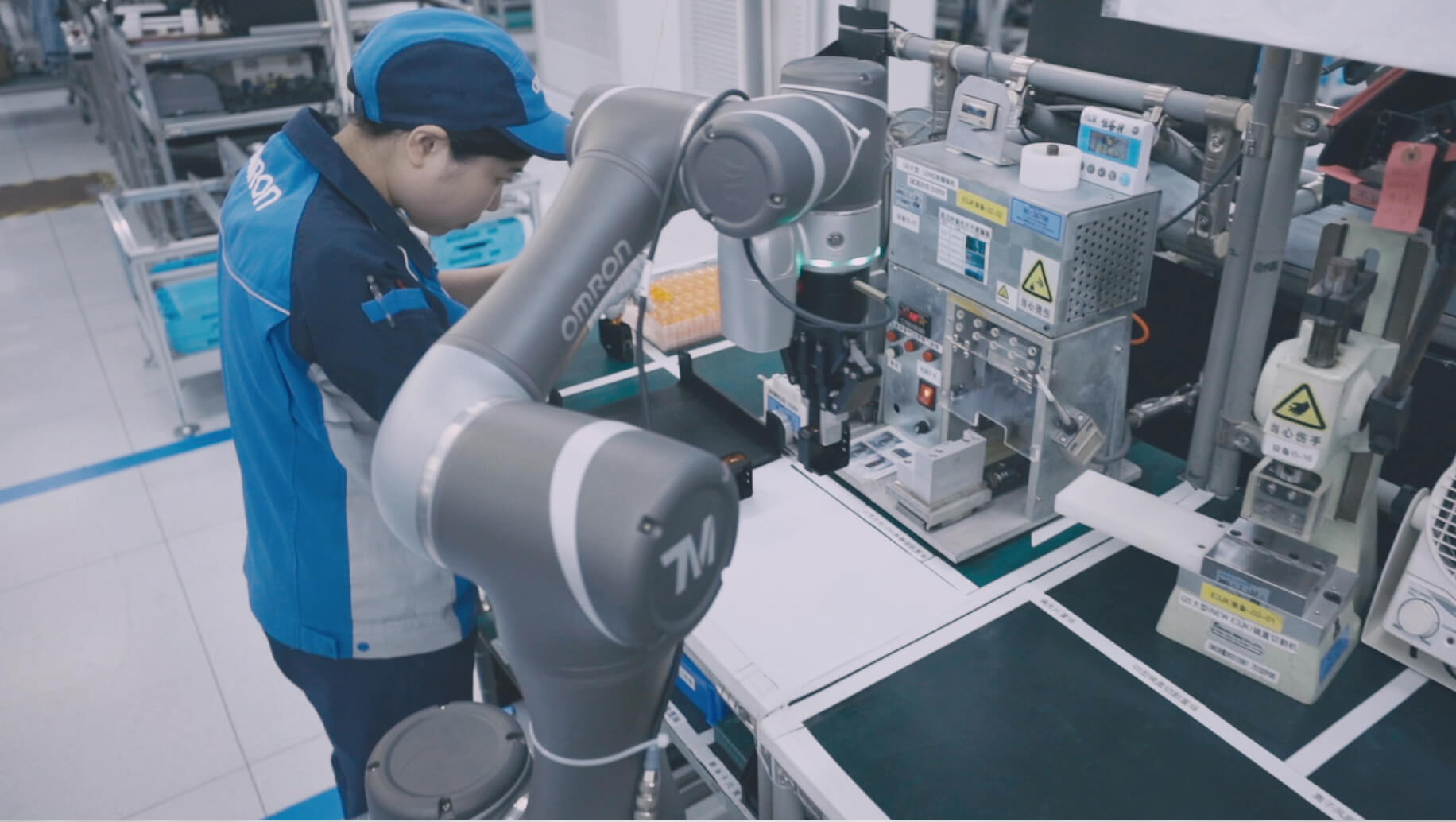

Cobots are smart robots that make work easier, safer and more efficient. Cobots are designed to work harmoniously alongside humans. Unlike traditional robots that require safety barriers, cobots are equipped with advanced sensors and built-in safety features. They can take care of repetitive or hazardous tasks, improving workplace safety and freeing workers for more strategic roles.

From manufacturing, logistics to healthcare and food & beverage, collaborative robots are boosting productivity, flexibility, and precision. They streamline tasks like assembly, material handling, and quality inspection, while adapting to changing business needs.

Contact us

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact me Cobots

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for Cobots

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadHuman robot collaboration. How it happens?

What does it take for humans and cobots to work seamlessly together and redefine the modern workplace? At the core of this collaboration lies the ability for humans and machines to work in harmony, prioritizing human well-being and potential. Check out real-world examples to see how cobots are making a difference in tech environments, simplifying tasks and creating efficiency.

What are cobots used for?

Curious about what cobots can do and where they are used? Cobots, are helping small to large businesses in various industries and in multiple applications. This article explains where cobots are integrated, when, and why they’re a smart choice for automation for any business.

Are cobots safe?

Cobots are designed with human safety in mind, but a thorough risk assessment is key to ensuring safe operation. Manufacturers need to consider potential hazards, such as emergency stops, clamping risks, and tool-related dangers like sharp edges or heat. By addressing these risks, cobot applications can run safely and efficiently, delivering better performance and results.

What are the benefits of using a cobot?

Cobots bring flexibility and adaptability to a wide range of industries, enabling businesses to automate without extensive reconfiguration or downtime. They are cost-effective, easy to program, have a small footprint, and can be redeployed for different tasks as needs evolve. Thanks to collaboration between humans and machines, cobots improve workflow efficiency and open opportunities for innovation and skill development within the workforce.

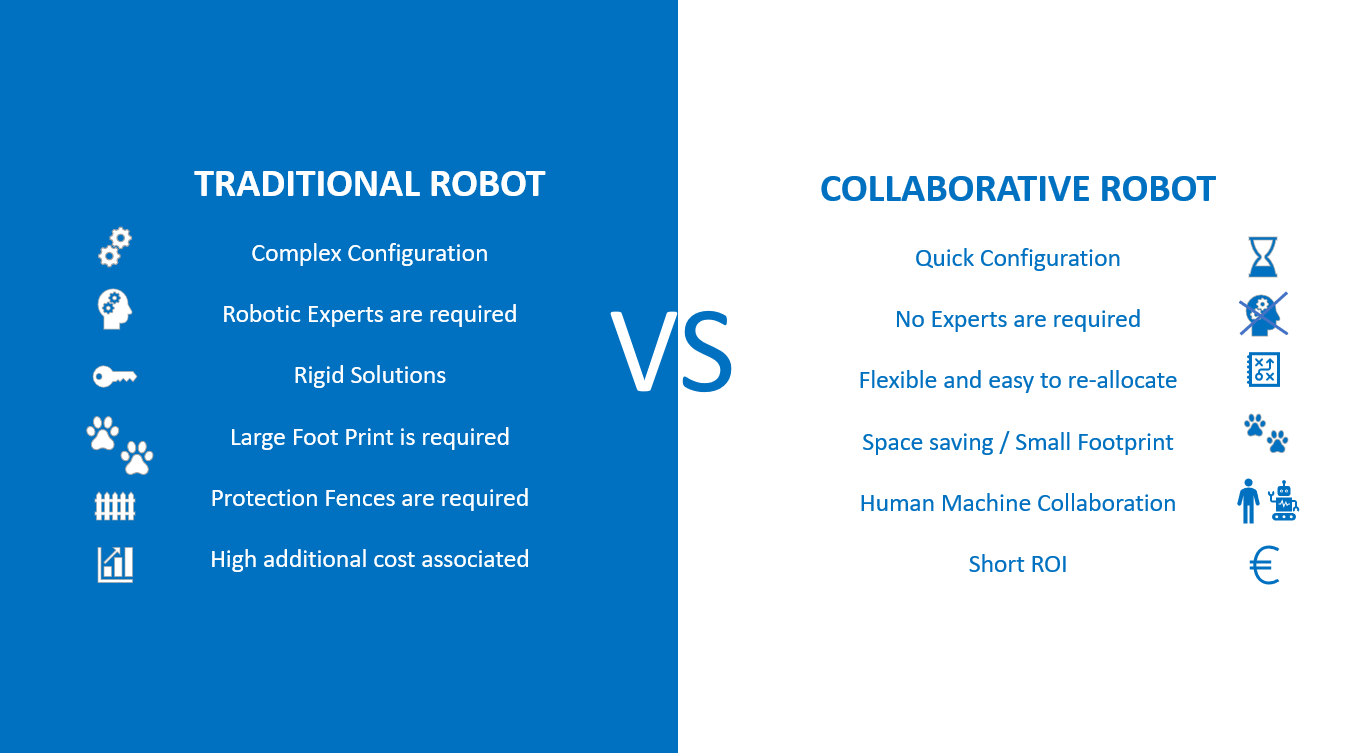

What is the difference between a robot and a cobot?

Traditional robots are the powerhouses of the factory, working autonomously behind safety barriers, ideal for consistent, repetitive tasks. In contrast, cobots are more like team players, designed to safely collaborate with humans in shared spaces, making them versatile and suitable for smaller setups. Choosing between robots and cobots depends on the specific needs of the task, as there's no one-size-fits-all solution in automation.

What are the different types of cobots?

Not all cobots are created equal. With a wide range of features and specifications, cobots can be customized to meet your exact needs. Choose the perfect partner for your project by focusing on factors like reach, load capacity, accuracy, speed, and the number of axes. Explore how our cobots can match your task with an ease.

How easy is it to train workers to use a cobot?

Cobots are designed to be user-friendly. With intuitive interfaces and simple programming, they are easy to use and even workers with minimal technical skills can quickly learn to operate them. The short learning curve empowers workers to quickly integrate them into daily tasks and benefits from them.

How much does a cobot cost and when can I see ROI?

Wondering about the cost and return on investment of a cobot? OMRON's new ROI calculator provides a quick and easy way to estimate the payback period for your specific automation project. By inputting details about your current operations and desired robot configuration, you can see the potential savings and efficiency gains. With flexible leasing options available, cobots can be a cost-effective solution, even for small and medium-sized enterprises.

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact me Cobots

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for Cobots

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download