E2EC

Sub-miniature inductive sensor for demanding mounting conditions with remote amplifier

The E2EC family features the smallest sensor heads for reliable sensing in areas where mounting space is crucial. The miniature sizes of the sensing heads are achieved by separating the sensing part from the amplifier. In contrast to standard separate amplifier models the E2EC family simplifies the installation as the amplifier is built into the cable.

- 3 mm diameter sensing head for smallest spaces

- 18 mm long ultra short M12 size housing

- Full metal housing model for highest resistance in demanding environments

Specifications & ordering info

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact me E2EC

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for E2EC

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadPerformance comparison

Changing temperatures

Changing temperatures - performance

| Issue: Temperature variations in machines resulting from the operation, from usage in different regions or even from daily or seasonal fluctuations are very common. The performance and specifications of electronic components are significantly influenced by the ambient temperature resulting e.g. in variations of the sensing distance. The design of electronic circuits, the usage of compensatory elements and the balance of used parts play a vital role in reducing the sensor performance variations due to changing temperatures. |

| Solutions: |

| * Market standard: basic temperature compensation for standard factory environment. |

| ** Designed-in enhanced temperature compensation elements with our E2A for higher operational stability in machine and factory environments even with higher temperature variations. |

| *** Highest temperature influence immunity by separating the sensing head from the electronic parts with our E2EC and E2C for high precision positioning applications with minimal influence by changing temperatures. |

Changing temperatures - lifetime

| Issue: Rapidly changing temperatures and different expansion coefficients can lead to mechanical stress between connecting materials leading to mechanical damage or faster aging. |

| Solutions: |

| * Market standard: sensors designed for standard factory environments – faster aging or damages may occur with frequently or rapidly changing temperatures. |

| ** Designed-in and tested enhanced lifetime with our E2A for machine and factory environments with frequently or rapidly changing temperatures. |

| *** Tested combinations of temperature and mechanical stress for special applications or certifications. |

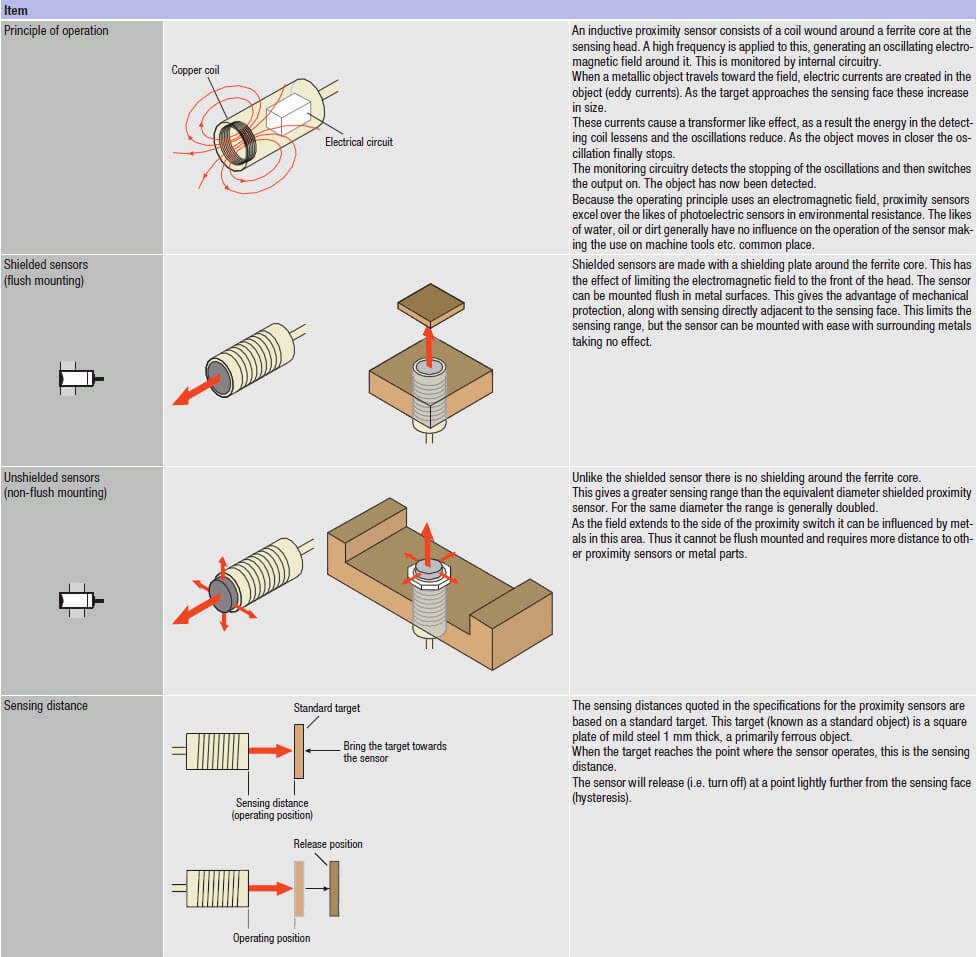

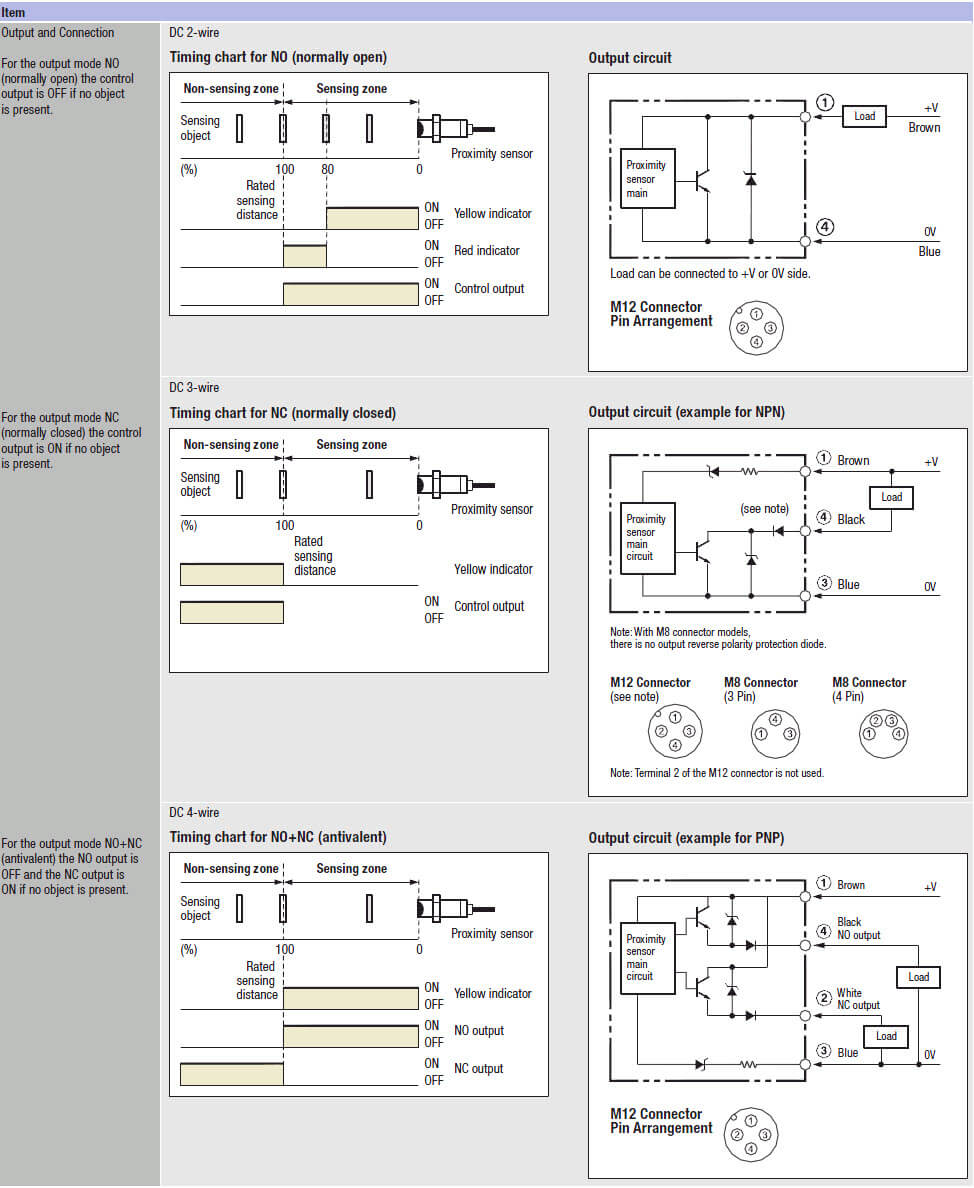

Technical information