Automation blog

Robotic Trends 2024: Simple and flexible application essential to reach full potential

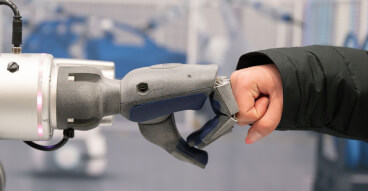

15 July, 2024 From load carrier to colleague to team player: the role of robots has changed dramatically over the past seven decades. AI is creating more possibilities, but humans remain the determining factor. Robots or humans – who will determine production in the future? Since George Devol's 1954 patent for a programmable manipulator, this question has sparked debate. Devol's Unimate robot revolutionized industry by safely performing dangerous tasks, highlighting that the focus isn't robots vs. humans but rather "robot + human = efficiency." Over 70 years, industry demands have evolved to prioritize flexibility, scalability, adaptability, and sustainability. Robots handle tasks that free humans to focus on value-added activities.

Joining the dots: Automating feeding activities for a competitive advantage

18 June, 2024 Developments in robotics are facilitating the conception of flexible line-side feeding and handling systems that can enhance safety, productivity and quality whilst addressing labour shortages. Factory automation usually starts with the dots. By this we mean the big ticket plant that performs complex and visibly value-adding tasks - whether that is flow wrapping, injection moulding, blister packing, bottling, palletising or other core manufacturing processes. The lines that join those dots together - handling, loading and feeding systems - tend to be more of an afterthought, to the point where these activities are often carried out manually. It might seem easier and cheaper to have an operator loading raw materials onto the production line, or feeding components into machines, rather than spending on automation. But this is a shortsighted view that misses the many business benefits that automated line-side feeding and handling can deliver in terms of efficiency, product quality, scalability and health & safety. It is also a view that is increasingly outdated given the pressure that the current labour crisis is exerting on the manufacturing sector.

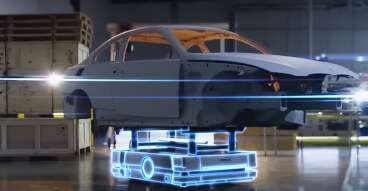

Top 4 challenges EV manufacturers face in their journey to achieving a sustainable future

17 June, 2024 Electric vehicles (EVs) have transitioned from a niche market to a major industry force in recent years. As of 2023, electric cars account for nearly one in five vehicles sold, with sales increasing by 3.5 million units—a 35% jump from the previous year, according to the IEA's Global EV Outlook 2024. This surge is expected to continue, with projections indicating that sales in emerging markets will exceed 1 million units in 2024, marking a 40% increase from 2023. Governments worldwide are pushing to reduce CO2 emissions, which is speeding up this shift to electric vehicles. So, what does this mean for automotive manufacturers? First, it means they need to pivot to designing and producing predominantly electric fleets, a move many have already started. Second, it means building new production lines and mastering new manufacturing processes, which can be quite a challenge. This is where a trusted automation partner comes in. Partnering with an expert in automation can help manage the complexities of this industry-wide transition. With a broad technology portfolio, global support, and deep automotive expertise, OMRON is ready to guide manufacturers on their electrified journey. This blog post will explore the top challenges in the EV manufacturing sector and how partnering with OMRON can provide effective solutions:

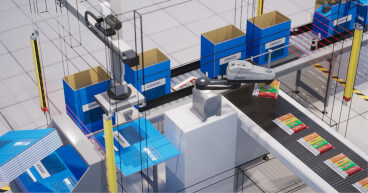

Transforming Logistics with Automation: Meeting Diverse Client Demands

05 June, 2024 The logistics landscape is evolving, with clients increasingly expecting comprehensive services, including personalised, customised, and seasonal packaging alongside various value-added services.Personalised Packaging:Consumers now want products that meet their exact specifications. This trend spans from everyday items to luxury goods, making it challenging to ensure the correct product is paired with the appropriate personalised packaging. The personalised packaging market is growing at over 5% annually. Surveys indicate that over half of consumers are more likely to repurchase from a vendor if they receive a product in personalised packaging.Customised Packaging:Customised packaging caters to specific client branding requirements to appeal to particular market segments, such as bulk-to-brand packaging in the retail sector for products like instant coffee, baby formula, or sealed foods. This often necessitates batch runs, which can be inefficient for manufacturers. Market research by Nielsen shows that 55% of consumers are willing to pay more for products designed for their segment or demographic group.Seasonal Packaging:Seasonal packaging significantly influences consumer buying decisions. A survey by the Paper and Packaging Board found that 44% of consumers say festive packaging increases their excitement about a product. Additionally, 60% of consumers are likely to share pictures of seasonally packaged products on social media, enhancing brand visibility and engagement.Many clients now request value-added services, including co-packing, labelling, and other enhancements that prepare the product for the consumer market.

Intelligent automation as an agent of change

31 May, 2024 The manufacturing industry is responsible for around a quarter of global GHG emissions¹, which puts it on a par with transport as the second biggest contributor to carbon emissions. This means that reducing the manufacturing sector’s carbon footprint will play a vital role in mitigating our impact on climate change.It’s time for the manufacturing industry to stop being a source of problems and start living up to its potential by being one of the sources of solutions, addressing climate change and utilising automation as the agent of change in the process.This reflects our founder’s belief that, as a business, we have a responsibility to give back to the society in which we operate. Over 90 years ago, OMRON was born out of the vision of its founder, Kazuma Tateishi, of using technology to create a better world.Tateishi’s ethos of “improving lives and contributing to a better society” has never been more relevant than in the present day, given the climate challenges we face as a society. But how can manufacturing make a positive difference?

The Future of Storing and Moving Stuff: Why Trying New Things and Teamwork Matter

10 April, 2024 In the rapidly evolving world of logistics, the industry dedicated to storing and moving goods is at a pivotal moment, marked by both unprecedented growth and daunting challenges. Over the last decade, storage space, particularly in the form of warehouses, has seen a remarkable expansion. Specifically, shed space has grown by 61% in the last decade and an impressive 22% in just the last three years. Despite the recent slowdown in e-commerce activity caused by the increased cost of living, the trend since 2015 is overwhelmingly positive and will continue to drive a strong demand for warehouse space in the future. However, as these storage spaces become more common, the industry faces a significant challenge: a growing labour shortage that threatens to slow down its expansion.

Even if it ain’t broke, you still oughta fix it

04 April, 2024 Making FMCG manufacturing more sustainable through intelligent energy management

Come on, ladies! Dare to explore exciting career opportunities in automation

01 March, 2024 Maryam Dolatabadi and Asunción Pastrana Costa are experienced automation experts at OMRON. They appeal to girls and women: “Be brave, you are urgently needed in the industry!”

Industrial automation and robotics: still a man’s world?

07 February, 2024 What is it like being a woman in automation today? Three women from OMRON Europe talk about their experiences in the world of industrial automation, the challenges they face, and the tools and support that have helped them to thrive.When Wendy Tonks first started her career in engineering in the UK just over 20 years ago, one of the first ground rules that she had to lay down was that she wasn’t a tea lady.

Embracing change: Breaking down the process of flexible manufacturing

30 January, 2024 The fast-moving consumer goods market is experiencing a transformative shift, driven by factors such as consumer empowerment, customization demands, health-conscious preferences, veganism, ethical concerns, and sustainability. We expect that it will undergo more changes in the next decade than it has in the previous 50 years. This necessitates the adaptation of production and supply chains to meet emerging trends. The future of fast-moving consumer goods factories will likely involve smaller, smarter facilities with autonomous movement of goods and interconnected systems.Machines, whether standalone or interconnected, need to be more flexible than ever before to ensure the timely supply of appropriate materials and packaging. Production has to be more agile, increasingly producing retail-ready items with a high mix-low volume approach with zero recalls. The question is how to realize this with minimal cost and fast ROI?

Unlock the Potential of UDI Compliance: Navigate the UDI Mandate with Confidence

08 January, 2024 Complying with the unique device identifier (UDI) system requirements is a critical milestone for medical device manufacturers, distributors, and end users. Ensuring compliance is not just about meeting a regulatory deadline; it's about safeguarding the integrity and safety of medical devices throughout their lifecycle in Europe and the United States.Our comprehensive whitepaper, "Ready for the UDI Mandate Deadline?" dives into the intricacies of UDI implementation, shedding light on the complexities beyond the surface. The ultimate goal is clear – to effectively identify and trace medical devices, from a simple bedpan to a lifesaving artificial heart, promoting safety across the healthcare landscape.However, the journey towards UDI compliance goes beyond merely affixing a printed barcode to a package. Establishing a robust system for verifying UDI markings, and ideally automating these processes, requires a thorough understanding of the means and methods involved. Inline verification during label generation and off-line validation in active service are pivotal components of a successful UDI system.In this whitepaper, we not only outline the UDI labeling requirements but also provide actionable insights into best practices. Discover how the medical device industry can ensure that marking methods are not only compliant but also meticulously verifiable. Elevate your understanding of UDI implementation and gain confidence in navigating the intricacies of the mandate.Don't miss out on this opportunity to empower your organisation with the knowledge needed to thrive in the era of UDI compliance. Download our whitepaper now to stay ahead in the evolving landscape of medical device regulations.

Revolutionise Automotive Manufacturing: Navigating the Traceability Frontier

08 January, 2024 The automotive industry is undergoing transformative shifts, marked by a transition to globalised platforms and standardised vehicle architectures. While this evolution enhances production efficiency, it simultaneously amplifies the impact of a single flawed part, raising the stakes for manufacturers. With the soaring costs of recalls and the intricacies of an ever-changing regulatory landscape, automotive production finds itself at the crossroads of complexity.Traceability emerges as a pivotal solution, promising to mitigate risks and enhance overall operational resilience. However, the prospect of marking up to 20,000 parts per vehicle triggers a valid concern among manufacturers. Is the effort truly worth the potential benefits? The challenge extends beyond mere marking to the implementation of reading and verification technology, coupled with the integration of sophisticated software solutions capable of harnessing the wealth of generated data. Download the whitepaper now to unlock a roadmap for success in navigating the intricate landscape of automotive traceability. Stay ahead of the curve and transform challenges into opportunities with the knowledge shared in this indispensable resource. Our whitepaper delves deep into the current trends and challenges of automotive traceability, unravelling the complexities that manufacturers face. Discover insightful strategies that not only justify the effort but also elevate the effectiveness of a real-time traceability system.

Building the Factory of the Future together

16 June, 2022 As one of the largest business units at OMRON, we aim to further develop the Den Bosch plant to serve the needs in the EMEA region.

Traceability in Automotive: What decision-makers and experts should look out for now

23 May, 2022 From e-mobility to autonomous driving, from skills shortages to digitalization: The automotive industry is undergoing a profound change, marked, for example, by a shift to globalized platforms and standardized vehicle architectures. On the one hand, production is becoming increasingly efficient, but on the other, even a single faulty part can have more far-reaching effects than ever before. Faced with costly recalls, automotive manufacturers are confronted with increasingly complex requirements and stricter specifications. Is the effort of traceability worth it if it means labeling up to 20,000 parts per vehicle? Yes, it is, but powerful reading and verification technologies along with powerful software is needed to make sense of all the data.There are several reasons why manufacturers need to keep accurate records of the parts and components that make up a new car. From a quality perspective, for example, barcode tracking helps to ensure that the right parts are put together. Even more important, however, is the ability to trace each car part back to its original supplier. In the event of a recall or the discovery of a faulty part, manufacturers have to be able to quickly and comprehensively find out where each part came from. This is complemented by information such as batch number, date of manufacture and other important information to identify which vehicles are affected by a defective part. Recommendations and standards from AIAG, VDA, ANSI and ISO specify the details. As the automotive industry globalizes, worldwide production of light vehicles is expected to reach around 96 million units by 2023. This means that even a single faulty part can have an enormous impact, and therefore must be prevented at all costs.

How the RB1200 Cobot Palletiser Can Simplify Your Automation Deployment

13 April, 2022 Greater automation and collaborative robotics (cobots) are the future for many industries, including logistics. Research by BMW found humans and robots work more than well together. In fact, human-robot teams were 85% more productive than working alone.It makes sense. Combining the speed and accuracy of robotics with the flexibility and intuition of humans compounds the benefits from each to build an unbeatable team.With the RB1200 Cobot Palletiser, OMRON, in collaboration with Reeco, is bringing a revolutionary new approach to end of line palletising. Creating an easy, flexible, safe, and compact solution to getting stock palletised and ready for transport.Palletising is a task perfectly suited to automation. The simple yet repetitive and physically demanding process of getting goods stacked leads to complications when performed manually. In 2019/2020, the Health and Safety Executive (HSE) estimated 19% of non-fatal workplace injuries were caused by handling, lifting, and carrying.Plus, given the labour shortages facing the UK and the wider world and the potential for spiralling staff costs, now is the ideal time to get your company less reliant on manual labour.While there are plenty of benefits to automating your palletising processes (greater output and accuracy, reduced labour and operational costs, etc.), its implementation also has challenges.However, with the RB1200 Cobot Palletiser, humans can collaborate with robotics on their terms, implementing a solution that fits their specific needs.

Mastering packaging and intralogistics challenges in eCommerce

24 February, 2022 Robot-assisted packaging enables fast and cost-efficient scalability upward and downward to handle swings in demands from the supply chain.

Hanover Displays automates PCBA testing with cobots

31 January, 2022 UK-based Hanover Displays Limited needed a new system for testing printed circuit board assemblies (PCBAs) and selected OMRON TM cobots for the job, supplied and installed by Absolute Robotics, part of the Absolute Automation Group.

Five challenges in High-Mix, Low-Volume (HMLV) packaging and palletizing processes

21 December, 2021 The new product has just left the factory, in a shelf-ready package in the specified mixed ratio to meet customer needs. The packaging has actually been handled by another company: a co-packer. Co-packing can be found in all Fast-Moving Consumer Goods (FMCG) markets, but especially in the higher-priced product segments such as personal care or confectionery, to name a few examples. It is a fast-growing activity to satisfy the consumer demand for more variety.

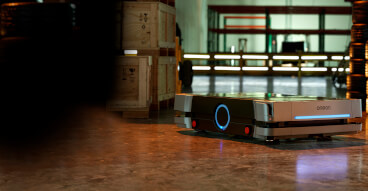

Rethink your Company’s Intralogistics Approach with Autonomous Mobile Robots (AMRs)

09 December, 2021 Intralogistics refers to the management and movement of materials and goods within a facility, and whether it is a warehouse, distribution centre, factory, or another production facility, it can be a significant hurdle to overcome. But by investing significant time and effort into your facility’s intralogistics, you can:

How Automating Tasks like Case Packing is the Logical Response to Record Vacancies

02 December, 2021 The UK is experiencing significant labour shortages across multiple industries. Brexit combined with the pandemic led to total UK job vacancies passing 1 million for the first time on record, and the food industry is one of the hardest-hit sectors. A lack of staff to call upon puts considerable strain on our food supply and creates headaches for employers around the country.Within the food industry, much of the focus has been on the shortage of lorry drivers and how this is causing higher food prices. However, a lack of staff is being felt across the industry in production, fruit/veg picking, packaging, and more.Strict travel restrictions due to Covid combined with Brexit means jobs previously performed by overseas workers remain unfilled. Plus, the pandemic and a break from the usual work cycle lead many people to re-evaluate their profession and look for careers that offer them increased flexibility and autonomy over when and where they work.A significant portion of the food industry vacancy problems is in less desirable positions that are low wage and physically demanding. Fortunately for employers, many of these jobs are ideal candidates for automation. Case packing is a great example of this.

Finished seals in less than 10 seconds: Robotics Integrated Controller ensures harmonious control

24 November, 2021 Trelleborg Livorno has updated a robotic cell for the finishing of polyurethane gaskets for the sustainable wind energy market. The cornerstone of the solution is OMRON's Robotics Integrated Controller that ensures integration and synchronization of all automation components, including robots, logic, motion, safety and user interface.

The Pitfalls of Manual Handling in End of Line Applications and Why Automation Is The Solution

18 November, 2021 No matter the industry you operate in, packaging, managing, and getting your inventory to where it needs to be is a significant headache. Businesses require robust and agile palletising processes that maximise efficiency, eliminate costly errors, and integrate seamlessly within wider workflows.Automating your end of line applications offers a range of tangible business benefits to increase output, reduce costs, and give your company a real competitive advantage.In the past, implementing new automated systems has been seen as too complex a process. The learning curve of integrating an entirely new system has appeared too steep to reach the benefits on the other end.But with new collaborative robotic systems, like the RB1200 Cobot Palletiser from Omron, automating your end of line processes has never been simpler. The RB1200 provides versatile and straightforward solutions for your palletising needs. The plug and play system with intuitive visual software can be configured in minutes to match the product and configuration you require.With advanced automation solutions for end of line applications, your business can simplify stock management and avoid the pitfalls associated with manual handling.Companies that rely on manual handling to stack and transport their goods are doing business on hard mode, making a complex task more difficult. The downsides of utilising manual handling in your end of line processes include:

Digitally Transform your Food Production Line using Smart Pick and Place Robot

17 November, 2021 A once in a generation labour shortage has put the UK food industry in a precarious position. Through a combination of Covid and Brexit, fewer workers being available is placing significant strains on food production and supply chains. A lack of:Delivery driversProduction line workersFruit pickersAbattoir staffAnd other workersHas led to instances of empty supermarket shelves with a growing number of missed food deliveries. Our food supply chains are beginning to feel the bite.

Manual Tasks in Manufacturing: Risky? Expensive? Both!

04 November, 2021 There are fewer people employed in the manufacturing sector now than at any other point in the last 25 years!! According to the Office for National Statistics, the 6- month period between October 2020 and April 2021 saw the lowest level of employment in the manufacturing sector since 1996. Conversely, consumer demand is at an all-time high. The impact of this is acutely felt in the food industry where a severe shortage of workers has led to unprecedented levels of job vacancies..

How Remote Connectivity can help your company through challenging economic times

27 February, 2023 What was supposed to be a period of recovery for the manufacturing industry post-pandemic has turned into anything but. Labour shortages persist, except now they’re compounded by high inflation, a looming recession, the conflict in Ukraine, and political mayhem at home. It can feel like every day brings another challenge to overcome. UK manufacturing was already at an inflection point, with businesses looking to transform their operations, introduce new technologies, and find ways to increase automation. Unfortunately, this can require an injection of capital that is harder to find at a time of financial uncertainty.As we round out 2022 with our third government of the year, we are still not sure how the new premiership of Rishi Sunak plans to solve the black hole that is the nation’s finances. But one thing is for certain, costs will rise, and UK manufacturing has a tumultuous road ahead. However, even when market conditions are tough, opportunities remain. In this blog, we will discuss the challenges of investing in new machinery, particularly given the economic outlook and how remote connectivity can help maximise its use while also minimising operational costs.

Artificial Intelligence: don’t call me stupid

08 February, 2023 Ten years ago I was quite proud of how smart the machines in our own factory were. Now, with my today’s definition of smart, I realise they were actually quite stupid.Why? Because although they were doing what they were designed to do, the minute they encountered anything unexpected or out of the ordinary they were stumped. They resorted to asking the operator ‘what is wrong with me?’.Troubleshooting and getting machines back up and running called for smart people. Highly skilled operators. Experienced software and hardware engineers. The problem is that in the last ten years, these people have become increasingly unavailable. There quite simply isn’t enough new talent entering the industry to offset the number of workers reaching retirement age. When they leave the business, retirees take with them their hard-earned on-the-job knowledge that is a culmination of years of experience. With each departing worker, businesses are faced with the prospect of a less productive and less skilled workforce.

Solving machinery downtime challenges with remote connectivity

07 February, 2023 Manufacturing machinery is a significant investment and every minute it isn’t running is a lost opportunity for your business. Studies show that unexpected machinery downtime costs industrial manufacturers an estimated $50 billion (USD) each year, and poor maintenance strategies can reduce capacity by 5 to 20%.With money on the line, organisations require production schedules that minimise downtime while still allowing for critical maintenance to ensure safety.

The path to net zero: talking tactics

01 February, 2023 The key to unlocking a net zero future in manufacturing is transforming the value chain through automation.In June 2022, New Scientist reported that a third of the world’s largest companies had net zero targets - significantly more than the same time last year.Whilst it is positive news that momentum is accelerating, the article went on to say that the details of how companies were planning to reach net zero were patchy.Which is not surprising really. Creating and implementing a net zero strategy is a huge undertaking for any business, especially with 80% of GHG emissions falling into Scope 3 - that is emissions that occur upstream or downstream in the value chain. This is a particular challenge for FMCG companies, whose supply chains and onward logistics are long and complex.Most of these businesses know what they need to do: decarbonise and circularise the value chain. And they have a strategy for doing this, which will generally cover: optimising the use of resources and energy, replacing high emission products and processes and eliminating waste.But translating intention into action is where the main challenge lies. This is where automation has a crucial role to play.Data collection and analysis is the key to successful net zero transition. Without it, how do companies know what their starting point is, where they need to improve, whether they have improved and by how much? Robust data is the foundation for turning a commitment into change, and for credibly and confidently communicating with stakeholders and delivering on climate ambitions.

Powering through the energy and fuel crisis with automation

07 December, 2022 To counter rising prices and meet environmental targets, industrial enterprises should explore how automation technologies from a single source might help contribute to their sustainability strategy.High energy and fuel prices are putting a strain on both households and industry. Not only is the situation negatively impacting financial plans and wallets, but the excessive prices are forcing some companies to cease production. According to Make UK 42% of manufacturers surveyed said that their electricity bills have increased by 100% in the past 12 months and 32% said that gas prices have increased by over 100% in the past year. A worrying 12% of manufacturers have already made job cuts as a direct result of increased energy bills.The war in Ukraine, Covid-19 pandemic, and gas pricing are only a few of the causes of the crisis, which impacts all sectors and has an impact on everything from power prices to supply chains. What should manufacturing companies consider now? Comprehensive automation strategies are essential for greater flexibility and energy efficiency. This includes innovative robotics paired with sensor and vision technology as well as artificial intelligence – AI at the Edge. In addition, real-time data from production plants can assist with detecting anomalies and improving overall equipment effectiveness (OEE).

Riders of the storm: navigating economic uncertainty by turning social challenges into tech opportunities

06 December, 2022 One of the questions I am often asked is what our strategy is, as an industrial automation business, for maintaining stable growth in a volatile and increasingly unpredictable global economy. My answer, as you might imagine, is not one sentence, although it is rooted in one concept: SINIC. SINIC stands for ‘Seed-Innovation to Need-Impetus Cyclic Evolution’ and is a theory that was developed by OMRON's founder, Dr. Kazuma Tateisi, in 1970. According to this philosophy, science, technology and society share a cyclical relationship, mutually impacting and influencing each other. Scientific breakthroughs help society to advance and social needs spur on technological development. OMRON Europe has always followed this philosophy, and has spent the last decade laying the foundations for creating value-adding solutions to present day social and economic challenges.

Where is the future heading, intralogistics? Tips for more efficiency

15 November, 2022 Sometimes we focus so much on the big picture that we forget the smaller and yet so important processes that characterize smart production. One example is intralogistics, i.e. the flows of materials and goods that take place on a company's premises or in a production hall. A recent study found that more than 80 percent of the companies surveyed consider the increased use of AI and automation in intralogistics to be necessary to meet challenges such as the shortage of skilled workers or growth plans.Automotive companies that want to meet market and customer requirements, increase efficiency and become more sustainable must come up with new ideas. Energy costs, the gas crisis, and rising inflation make this task even more difficult. Smart factory concepts that combine innovative automation, digitalization, and smart intralogistics approaches can provide valuable support. Some speak of Industry 4.0 in this context, others of the “factory of the future”, still others prefer Industrial Internet of Things (IIoT). But no matter which term you favor: The most important thing is to become active now and to rely on reliable partners. Intralogistics is a good starting point for quickly initiating change. Because action is urgently needed: many companies are currently severely limited due to the shortage of skilled workers. Modern technologies such as mobile robots can provide a remedy.

Digitalization in the automotive industry: Seven tips for smart production

02 November, 2022 If you want to grow and master crises, you have to be digitally fit – this also applies to the important automotive sector. There is no way around digital tools for addressing customers or productivity. Artificial intelligence (AI) and sustainability are key drivers and focus topics, as a study by Capgemini shows. Experts from Gartner point out the importance of open-source collaboration approaches, holistic ecosystems, and technology partnerships. But what should we look out for in digitalization and intralogistics in the production of the future? We want to answer this question in two parts. We start with tips on digitization in the smart factory. As an automation expert, OMRON has been accompanying manufacturers and suppliers on their way to more digitalization sophistication for many years.

Artificial Intelligence: hope, hype and FOMO

22 September, 2022 Ten years ago when we received enquiries about AI-based projects, they were mainly driven by hype or FOMO. When I asked why they wanted to get into AI, the answer, more often than not, was either ‘because my boss asked me to’, ‘because we have a lot of data’ or ‘because it seems like an interesting area’. None of these were particularly solid reasons and certainly didn’t justify the hefty investment that AI applications would have required at that time.That is changing, and hope, rather than hype or ‘FOMO’, is the driver. Customers don’t ask whether we can help them with AI anymore. They ask us whether we can help with predictive maintenance, quality control or process optimisation. They come to us with a problem that they want us to help solve. The adoption of AI is no longer a motive or an aim in itself. Instead, AI has become an ‘enabler’.Whatever the industry - whether food & drink, pharmaceutical, electronics or automotive - the end goal is the same: producing high quality, defect-free products at a lower cost, using less energy and less labour. And AI can be one of a suite of solutions for achieving those objectives.

Automation adapts to sustainable packaging

16 August, 2022 Have you ever ordered a small item online, and then felt incensed when it arrived in an oversized box packed out with bubble wrap, air-filled cushions or paper inserts?

Building the Factory of the Future together

16 June, 2022 As one of the largest business units at OMRON, we aim to further develop the Den Bosch plant to serve the needs in the EMEA region.

Lights out? Still unlikely with Industry 4.0

21 April, 2022 For many manufacturers, the prospect of a fully automated, human-free factory feels light years away. When, they ask, is the 4th Industrial revolution coming to us and what can we expect? In this blog, we look at the realities of (fully-/semi-)automated manufacturing, what robots can and can’t do, and why the human touch is still (mostly) irreplaceable.

Combatting counterfeiting, promoting ethical sourcing and minimising recalls

26 April, 2023 In the third blog in this series on Traceability we will discover how counterfeiting has become a major issue in the food and beverage sector and how effective labelling can aid in a host of verification related tasks.Counterfeiting has become a major problem in the food and beverage industry as the market becomes more globalised. Several types of fraud exist, they can appear alone or in a combination in food fraud.Dilution - mixing a liquid ingredient of high value with a liquid of lower value.Substitution - replacing an ingredient, or part of the product, of high value with another ingredient, or part of the product of lower value.Concealment - hiding the low quality of food ingredients or product.Mislabelling - placing false claim on packaging for economic gain.Unapproved enhancement - adding unknown and undeclared materials to food products to enhance the quality attributes.

Buying or Leasing? How to finance your new cobot

26 April, 2023 Food for thought for SMEs when funding automation projectsSkills shortages, digitization, sustainability, and energy-saving plans are accelerating automation projects in many companies. Once manual processes that lend themselves to automation have been identified, the next question that usually follows is: And what does it all cost?It can make sense to consider options such as leasing or robot-as-a-service. One example of tools that give small and medium-sized enterprises (SMEs) in particular a better overview the financial aspects of automation is the ROI calculator from OMRON. Anyone currently considering the purchase of a cobot or AMR can use this tool to reveal the return on investment.

Complying with industry regulations

20 April, 2023 In the second blog in this series on Traceability we will discover how complying with industry regulations is essential in today’s manufacturing process, especially in industries like food, beverage and pharmaceutical and what the legal requirements are set out by the FSA.A lack of a comprehensive traceability system can potentially have disastrous outcomes for everyone in the supply chain, from producer to consumer. Paper does not control anything. It is just a written record, there’s no validation, and no control.In the food and beverage industry, authenticity is essential. Consumers need to know that the foods they are purchasing consist of the things listed on their labels, as food allergies and expired foods can cause serious illness and possibly death. Since both public health and consumer satisfaction depend so heavily on product integrity, the food and beverage packaging industry is highly regulated.One of the main things mandated by food and beverage regulation is “traceability” the practice of maintaining thorough records on the origins and whereabouts of products and raw materials by scanning printed barcodes, direct part marks (DPMs) or radio frequency identification (RFID) tags throughout the production process and the supply chain. From raw materials supplier to production line to supermarket to customer, the creation and distribution of a particular food item should be as transparent as possible.Food and beverage manufacturers also benefit directly from traceability protocols that minimise the occurrence and effect of costly issues such as product recalls by providing real-time data on supplier materials, processes and machinery involved in production. These protocols can significantly reduce cost of a recall by isolating tainted items and making it unnecessary to pull large amounts of non-tainted product off the shelves.Regulations are one of the primary forces spurring food and beverage manufacturers to adopt robust traceability systems. In the United Kingdom, the foremost source of regulation is the Food Standards Agency.After a number of high-profile outbreaks of food related illnesses in 2000, the Food Standards Agency (FSA) was established as an independent government department working to protect public health and consumers’ wider interests in relation to food in England, Wales and Northern Ireland.In the wake of Brexit, food and beverage regulations in the United Kingdom have changed and evolved while retaining some relevant provisions laid out in EU legislation. While Northern Ireland remains subject to EU law alone, Great Britain, Wales and Scotland fall under the provision of the Food Standards Agency (FSA) as the government organisation responsible for setting and enforcing traceability requirements.A quick reference guide published by FSA specifies that food business operators (FBOs) must maintain traceability information for suppliers and customers—equivalent to the “one step forward, one step backward” model which means they must be able to identify the businesses to which their products have been supplied and to trace food chain inputs back to the immediate supplier.

4 Steps to Optimise Manufacturing Operations Using Production Data

17 April, 2023 Bottlenecks and other production issues are the scourge of efficiency, costing businesses thousands, if not millions, a year through delays, disruptions, wasted resources, and lost output. Based on your assets (staff, equipment, facilities, etc.), what should your business be capable of producing? Most businesses have at least done a back of an envelope calculation on what their optimum output could be, if not taken the time to do a detailed analysis breaking down every process in the production chain. How far off is your actual throughput compared to the best-case scenario? In highly competitive markets with shrinking margins and a challenging economic forecast, businesses have to find ways to maximise their operations, getting as close as possible to optimal performance. They can no longer accept inefficient processes such as:Unbalanced assembly linesLong changeover timesMinor discrepancies compounding to increase the failure ratePoor equipment efficiency or extended maintenance downtimeUntrained staff slowing productionThankfully, manufacturing has come a long way. With the integration of new technologies (robotics, IoT, AI, etc.), companies can generate and track considerable production data. However, having data is just the start. To impact your operations for the better, businesses must derive actionable insights from it. Listed below are four steps to help businesses identify and resolve production issues.

3 Reasons Leasing De-Risks Investments in Robotics

17 April, 2023 With skyrocketing energy bills, supply chain chaos, high interest rates, staff shortages, and the cost of living crisis reducing consumer demand, UK businesses feel like they are being hit from all sides at the moment.The economic outlook is challenging. Rising costs are squeezing profit margins forcing companies to charge higher prices or reduce output. In fact, the UK economy is the only G7 member yet to rebound to its pre-pandemic size. Industries struggling include manufacturing, which shrank by 4% in 2022 and is expected to decline another 3.2% in 2023, and logistics, which saw low levels of new warehousing space requirements at the end of last year. Companies looking to upgrade or expand are being held back by difficult economic conditions, in particular higher borrowing costs. When credit is cheap and readily available, businesses can make significant capital expenditure (capex) investments, transforming their operations to reduce costs in the long run or increase output and boost revenue. For manufacturing and logistics companies, high interest rates reduce the viability of investing in new technologies such as collaborative robots (cobots) and autonomous mobile robots (AMRs). In competitive industries where productivity is key, this puts many operations at risk of falling behind the competition. Thankfully, there is another option available. OMRON offers leasing options to help businesses acquire market-leading equipment without the risks associated with capex investments during tough economic times. Leasing advanced robotic equipment provides critical financial and operational benefits for companies looking to upgrade their operations.

Accelerating socially driven innovation

28 March, 2023 Society is built on cultural norms and values that shape how people think, behave, and interact with each other. These cultural factors can influence everything from consumer preferences and business practices to political beliefs, which in turn affect how manufacturing evolves.Manufacturing is one of the most important sectors of any economy, yet in the UK it can fairly claim to be underrated - despite our being the world’s 9th largest manufacturing nation. According to MAKE UK research, manufacturing provides 2.7 million jobs, has an annual output of £191 billion, and offers wages 13% higher, on average, than the rest of the economy.The sector also has a multiplier effect which extends far beyond the jobs and wealth it creates directly, supporting the growth of other industries and creating a positive cycle of economic growth - boosting the overall productivity of the country and improving lives.

How Remote Connectivity can help your company through challenging economic times

27 February, 2023 What was supposed to be a period of recovery for the manufacturing industry post-pandemic has turned into anything but. Labour shortages persist, except now they’re compounded by high inflation, a looming recession, the conflict in Ukraine, and political mayhem at home. It can feel like every day brings another challenge to overcome. UK manufacturing was already at an inflection point, with businesses looking to transform their operations, introduce new technologies, and find ways to increase automation. Unfortunately, this can require an injection of capital that is harder to find at a time of financial uncertainty.As we round out 2022 with our third government of the year, we are still not sure how the new premiership of Rishi Sunak plans to solve the black hole that is the nation’s finances. But one thing is for certain, costs will rise, and UK manufacturing has a tumultuous road ahead. However, even when market conditions are tough, opportunities remain. In this blog, we will discuss the challenges of investing in new machinery, particularly given the economic outlook and how remote connectivity can help maximise its use while also minimising operational costs.

Artificial Intelligence: don’t call me stupid

08 February, 2023 Ten years ago I was quite proud of how smart the machines in our own factory were. Now, with my today’s definition of smart, I realise they were actually quite stupid.Why? Because although they were doing what they were designed to do, the minute they encountered anything unexpected or out of the ordinary they were stumped. They resorted to asking the operator ‘what is wrong with me?’.Troubleshooting and getting machines back up and running called for smart people. Highly skilled operators. Experienced software and hardware engineers. The problem is that in the last ten years, these people have become increasingly unavailable. There quite simply isn’t enough new talent entering the industry to offset the number of workers reaching retirement age. When they leave the business, retirees take with them their hard-earned on-the-job knowledge that is a culmination of years of experience. With each departing worker, businesses are faced with the prospect of a less productive and less skilled workforce.

How to speed up cobot integration

08 February, 2023 Good planning and strong partners help SMEs overcome hurdles in automation.Collaborative robots, also known as cobots, are enjoying great popularity because they make it possible to automate time-consuming and resource-intensive tasks. The global market for collaborative robots is currently estimated at around $1.2 billion. The sales volume of cobots reached a total of 32,300 units in 2021. Especially in times when it is becoming increasingly difficult for companies to find and retain suitable employees, such technologies are worth their weight in gold in many places. Speaking of gold, some may ask: Cobots must be extremely expensive, right? When does such an investment pay off?Automation expert OMRON would like to alleviate such worries, especially for small and medium-sized companies: Smart and integrated robotics solutions as well as cobots and mobile robots are feasible and affordable. For those who want to estimate the return on investment, OMRON’s ROI calculator provides a quick and easy overview.Cobots and autonomous mobile robots (AMR) are suitable for both SMEs and large-scale businesses. They perform tasks such as transport, palletizing, loading and unloading of machines, assembly, painting, or welding. They can be quickly and flexibly retooled and also programmed by non-experts. Material replenishment can be streamlined with AMRs, and machine and process loading with cobots. However, to successfully carry out such projects and accelerate robot integration, know-how and partners who are familiar with the subject matter are needed. And above all, employees must be informed and involved from the start of the project to be part of the change together.Here are some tips companies should keep in mind when integrating cobots:

Solving machinery downtime challenges with remote connectivity

07 February, 2023 Manufacturing machinery is a significant investment and every minute it isn’t running is a lost opportunity for your business. Studies show that unexpected machinery downtime costs industrial manufacturers an estimated $50 billion (USD) each year, and poor maintenance strategies can reduce capacity by 5 to 20%.With money on the line, organisations require production schedules that minimise downtime while still allowing for critical maintenance to ensure safety.

Where is the future heading, intralogistics? Tips for more efficiency

15 November, 2022 Sometimes we focus so much on the big picture that we forget the smaller and yet so important processes that characterize smart production. One example is intralogistics, i.e. the flows of materials and goods that take place on a company's premises or in a production hall. A recent study found that more than 80 percent of the companies surveyed consider the increased use of AI and automation in intralogistics to be necessary to meet challenges such as the shortage of skilled workers or growth plans.Automotive companies that want to meet market and customer requirements, increase efficiency and become more sustainable must come up with new ideas. Energy costs, the gas crisis, and rising inflation make this task even more difficult. Smart factory concepts that combine innovative automation, digitalization, and smart intralogistics approaches can provide valuable support. Some speak of Industry 4.0 in this context, others of the “factory of the future”, still others prefer Industrial Internet of Things (IIoT). But no matter which term you favor: The most important thing is to become active now and to rely on reliable partners. Intralogistics is a good starting point for quickly initiating change. Because action is urgently needed: many companies are currently severely limited due to the shortage of skilled workers. Modern technologies such as mobile robots can provide a remedy.

Artificial Intelligence: hope, hype and FOMO

22 September, 2022 Ten years ago when we received enquiries about AI-based projects, they were mainly driven by hype or FOMO. When I asked why they wanted to get into AI, the answer, more often than not, was either ‘because my boss asked me to’, ‘because we have a lot of data’ or ‘because it seems like an interesting area’. None of these were particularly solid reasons and certainly didn’t justify the hefty investment that AI applications would have required at that time.That is changing, and hope, rather than hype or ‘FOMO’, is the driver. Customers don’t ask whether we can help them with AI anymore. They ask us whether we can help with predictive maintenance, quality control or process optimisation. They come to us with a problem that they want us to help solve. The adoption of AI is no longer a motive or an aim in itself. Instead, AI has become an ‘enabler’.Whatever the industry - whether food & drink, pharmaceutical, electronics or automotive - the end goal is the same: producing high quality, defect-free products at a lower cost, using less energy and less labour. And AI can be one of a suite of solutions for achieving those objectives.

Zero-defect philosophy helps resolve the world’s future issues

05 June, 2020 Imagine the city center of a modern metropolis in 2030: a multitude of unmanned, electrically-powered vehicles driving swiftly and silently through the streets. These vehicles sense traffic lights and other road signs and make decisions using artificial intelligence. They avoid people, who unexpectedly cross their path. They detect and avoid dangerous situations before they occur. And they contribute to everyone’s health and safety. But what happens if the associated electrical systems fail? Omron is already addressing this problem today.

Energizing European battery cell production

01 May, 2020 What can European automotive companies do to future-proof their production lines, especially in relation to battery manufacturing? Robotics, automated quality control and artificial intelligence (AI) can help companies to tackle the strong competition they are facing from Asia.

Integrated data control, motion control and machine vision for next-generation automotive production line

24 April, 2020 The Mexican regional headquarters of a leading manufacturer of premium air brake actuators for global on-highway and specialty markets required a new automated production assembly line. One of the company’s key performance indicators is to deliver a fully assembled product every 30 seconds, and it is with this end goal at the forefront that the team started the process of automating the production line.

ŠKODA AUTO uses LD mobile robot at Vrchlabí plant

17 March, 2020 The autonomous robot contributes to the continuous improvement of work safety in Vrchlabí and helps to minimise work risks. It recognises people crossing its path as well as other vehicles and stationary obstacles.

Green is key: sustainability in battery manufacturing for E-mobility

05 February, 2020 Today, sustainability is no longer a niche topic, but something that companies are integrating into their business strategies. Not only are sustainability practices necessary to answer the changing demands of consumers, the marketplace and governments, they are also increasingly being seen as a competitive strength. That’s because sustainability practices reduce energy consumption and waste, and also help companies use their resources more efficiently. They even help companies optimize their manufacturing agility and enable them to respond to fluctuating demand and the growing need for personalization. And finally, sustainability can play an important role in acquiring and retaining customers, as well in developing new market opportunities.

Agile and clever tailor-made mobile robotics

04 November, 2019 Major German automotive group optimizes efficiency and innovation leadership in material handling with Omron LD mobile robots and a conveyor attachment from cts GmbH.Automobile production and assembly line production have always been closely linked. It was not until Henry Ford began using conveyor belts in his factories in 1913 that the car was able to conquer the world as a mass-produced product. Today, a working day without assembly lines is inconceivable at the BMW factories. The group relies on innovative transport and logistics to increase efficiency and flexibility, to better link work processes, as well as to relieve employees from repetitive and time-consuming tasks. These concepts include Omron LD mobile robots for material transport that deliver a particularly high return on investment (ROI). These autonomous mobile robots are equipped with a conveyor tower - a height-adjustable load handling device, developed by system integrator cts GmbH. The interaction between employees and transport robots at BMW impressively demonstrates how factory harmony can be implemented in the factory of the future.