Re-packing / Co-packing involves the use of robotics and automation technology in unpacking and repacking operations. By automating manual re-packing tasks, businesses can increase efficiency, scalability, and affordability.

Our solutions adapt to product variability, ensuring flexibility and productivity in various packaging tasks.

Challenge

Customers in the repacking / co-packing industry face challenges such as handling a wide variety of product types, packs, cartons, and trays. Manual processes are inefficient, labor-intensive, and error-prone, leading to increased costs and reduced productivity.

Seasonal demand fluctuations further complicate maintaining consistent performance and meeting production capacity needs, affecting overall operational efficiency.

Solution

Our robotic and automation solutions provide flexiblity to adapt to product variability. Key applications include cobots/robots for case erection, pick and place operations, and palletizing.

Our solutions enhance productivity and efficiency, offering scalability and affordability. They support various tasks like repacking, mixed cases, relabeling, and carton closing, ensuring consistent quality and reducing labor costs.

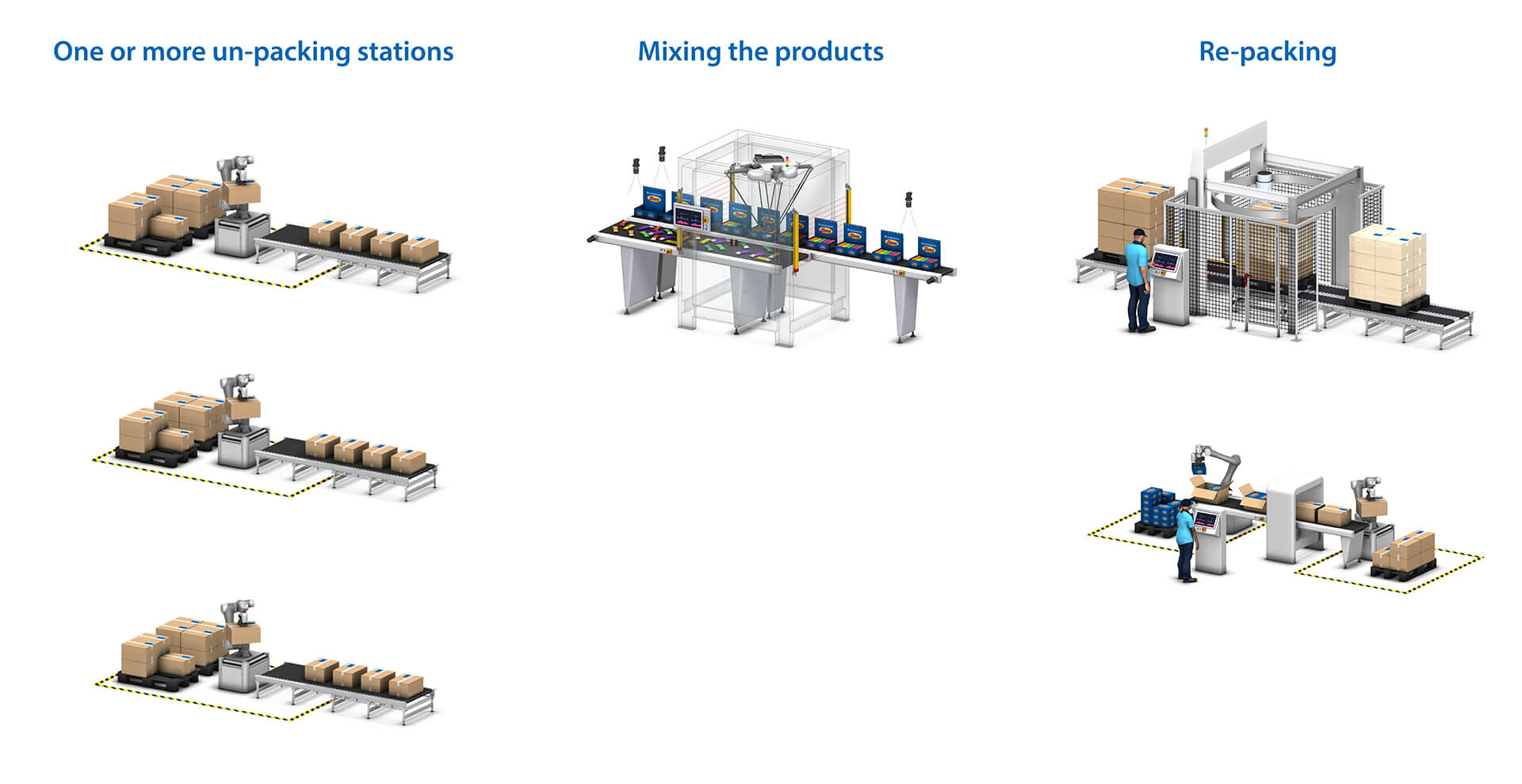

Typical Concept

Enhanced efficiency in copacking operations

Our solution can significantly boost productivity and efficiency for numerous repacking / co-packing operations:

- OMRON cobots for automated case erection, pick and place, and palletizing.

- Scalable according to production capacity needs with OMRON's Sysmac technology.

- Affordable automation technology that meets seasonal demand fluctuations.

- Versatility in handling different tasks such as repacking, mixed cases, relabeling, case forming, tray forming...