Flexible Manufacturing

Flexibility also means implementing changes is a smooth production process. Risking to introduce disruptions in a process finetuned for the highest efficiency. The question is this how to implement changeovers with minimal cost and fast ROI.

Adaptation of production and supply chains

To achieve an optimal solution with maximum flexibility in production, it is important to consider many different factors.

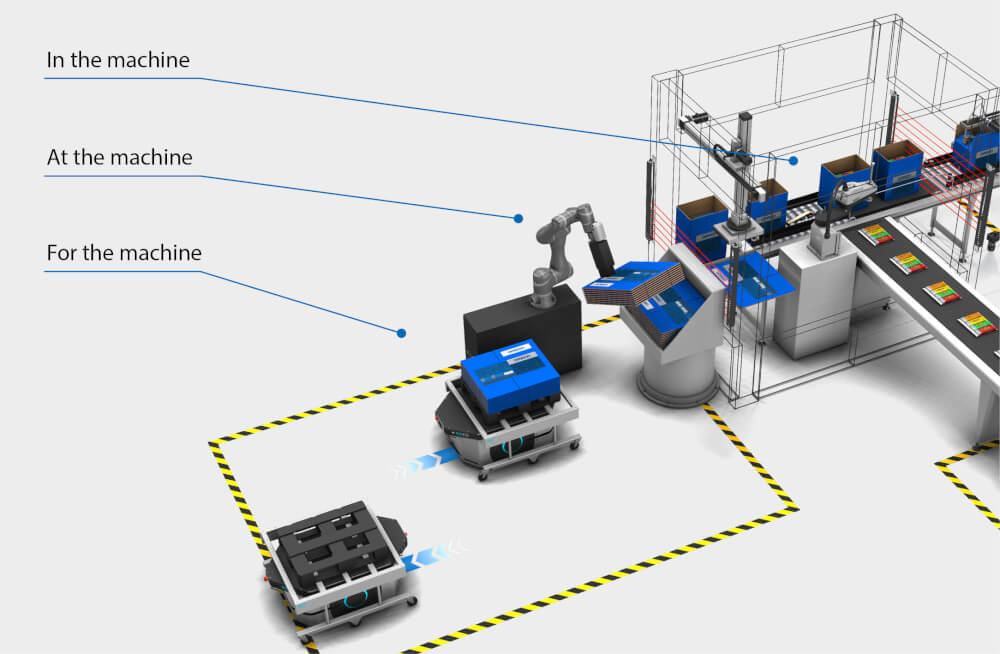

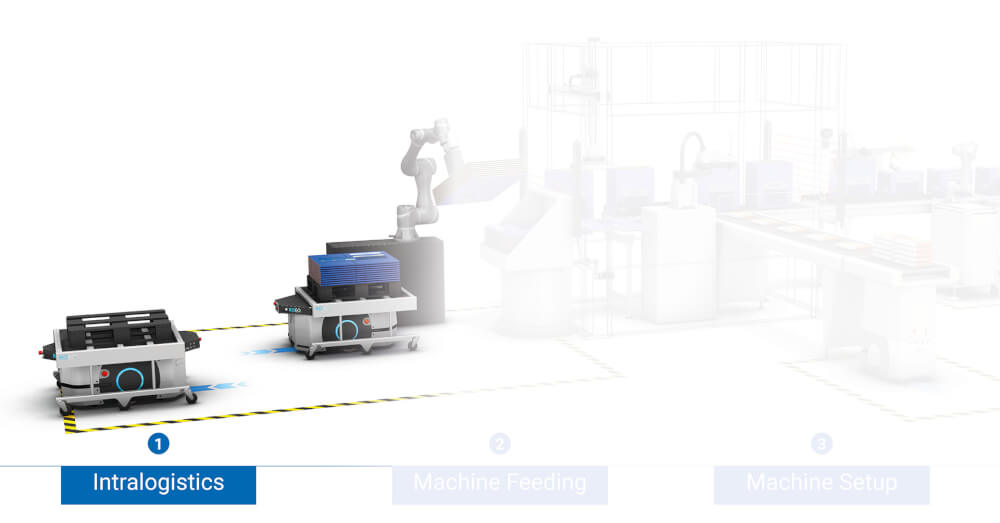

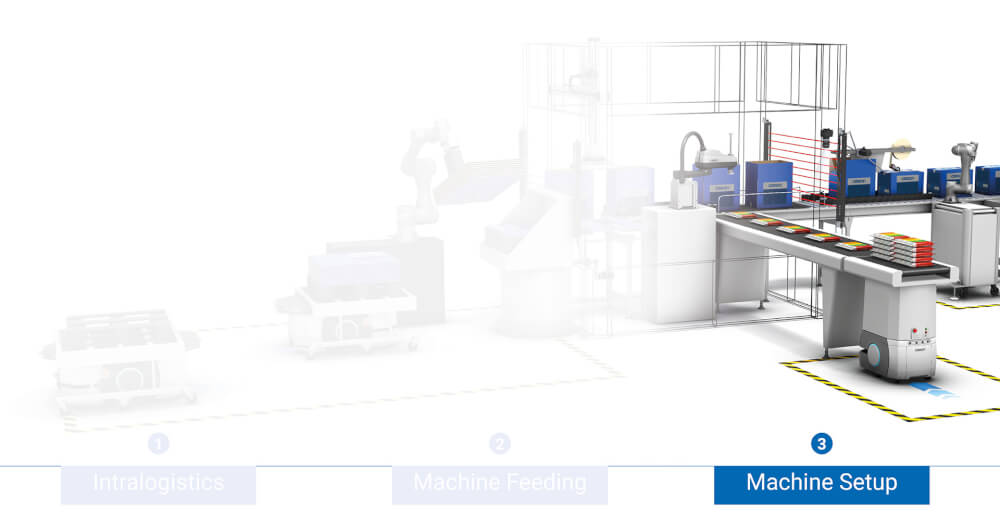

A practical approach involves breaking down the workflow into functional levels to ensure agile manufacturing processes.

Flexible manufacturing system: Workflow in three levels

Delivery of goods and consumables to the line

Automating intralogistics to reduce human movement for low-added-value tasks. Autonomous mobile robots (AMRs) from OMRON help create a modern, flexible shop floor.

Persons-to-Goods or Goods-to-persons

In the gathering process, a warehouse operator loses lots of time to move around through the warehouse. See how autonomous mobile robots support the operator.

Safely move pallets to and from the warehouse

Integrating high-end safety solutions without impacting productivity while connecting conveyors with autonomous mobile robots to reduce production footprint.

Conveyor Management

The consistent movement of products requires synchronized production processes. OMRON offers solutions in the form of a library of functional blocks, effectively reducing the time needed for the development of PLC program code.

Consumables feeding

Recruiting and retaining operators for loading cartons in a carton tray forming machine is quite a challenge for producers in the fast-moving consumer goods (FMCG) industry. See an example of an OMRON part

Cobot based palletizing

Easy to install and configure palletizing solutions. OMRON and its partners offer a complete palletizing solution. Integrating cobot, PLC & HMI with the complete sequencing performed from

Machine customisation

Machine builders design their machine modular, allowing for both customization to customer needs (adding options) and easy configuration changes on the shop floor. See how OMRONs Sysmac platform simplifies the customisation process here.

Adaptive Inspection

To meet the requirements of consumers, producers provide a growing number of variations in their products & packages. At the same time ensuring zero complaints and zero defects is a must. This requires a dedicated and advanced systems for quality control.

Automatic repacking for the retail channel

Repacking from single variety to mixed cases creates several challenges. To handle & optimize the inflow of different goods, OMRON brings together a complete line of robotic automation products into a single, fully integrated packaging system.

Optimum Flexible Manufacturing ensures

-

Safe Floorspace

Autonomous Mobile Robots eliminate the need for as "point-of- use” storage of the different versions of the consumables.

-

Uninterrupted Supply

Cobot-based automatic feeding of consumables combined with real-time verification of the packaging materials to be used.

-

Smooth Operations

One controller platform to automatically align all functions such as motion, robotics, sensing, vision, and safety in a smart factory system.

-

Increased Quality

Automated inspection and verification of the various product & package variations before shipment.

-

Operator support

The right info to effectively supervise the production or packaging line, reducing downtime to minimum.

Flexible Manufacturing technology

Customer References, Examples and Related Articles

Machine customisation

Machine builders design their machine modular, allowing for both customization to customer needs (adding options) and easy configuration changes on the shop floor. See how OMRONs Sysmac platform simplifies the customisation process here.

Fit for the future thanks to retrofitting

Machines in food and beverage production have to be reliable, safe, fast, and maintain quality over many years and even decades.

Vetipak enjoys the sweet taste of success thanks to robotics

Packaging solution with robotics integrated control ensures scalable processes and high-quality contract manufacturing in FMCG