How Automating Tasks like Case Packing is the Logical Response to Record Vacancies

Published on 02 December, 2021 in Flexible Manufacturing

The UK is experiencing significant labour shortages across multiple industries. Brexit combined with the pandemic led to total UK job vacancies passing 1 million for the first time on record, and the food industry is one of the hardest-hit sectors. A lack of staff to call upon puts considerable strain on our food supply and creates headaches for employers around the country.

Within the food industry, much of the focus has been on the shortage of lorry drivers and how this is causing higher food prices. However, a lack of staff is being felt across the industry in production, fruit/veg picking, packaging, and more.

Strict travel restrictions due to Covid combined with Brexit means jobs previously performed by overseas workers remain unfilled. Plus, the pandemic and a break from the usual work cycle lead many people to re-evaluate their profession and look for careers that offer them increased flexibility and autonomy over when and where they work.

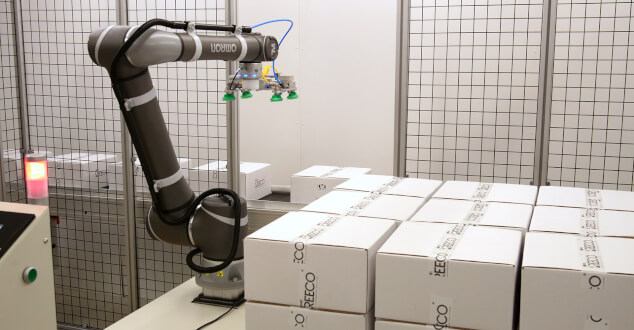

A significant portion of the food industry vacancy problems is in less desirable positions that are low wage and physically demanding. Fortunately for employers, many of these jobs are ideal candidates for automation. Case packing is a great example of this.

What is Case Packing?

Case packing is one of the final stages in food production. It refers to the packaging of food items before transport and delivery. While many companies already automate this process, a significant amount (particularly smaller operations) still package their food products by hand.

Even in a fully staffed scenario, case packing is a difficult job. It is a monotonous task that often requires employees to lift heavy items and perform repetitive movements that lead to Repetitive Strain Injuries (RSI).

Impact of Labour Shortages

Less staff available means companies struggle to maintain their output. As a result, many have to ask their remaining employees to work longer hours or find ways to increase productivity, pushing staff to package more products in less time.

This approach is unsustainable, though, leading to tired and overworked employees. Studies have shown overworking employees produces a range of health problems, including:

- Lack of sleep

- Impaired memory

- Depression

- Heavy drinking

- Diabetes

- Heart disease

While increased health risks are an obvious concern to employees, they also pose considerable problems to employers. Overworking employees backfires in the form of higher absences, more turnover, and an increase in mistakes.

Research shows 76% of UK employees admit they make more mistakes when tired. In case packing, even minor errors can compound and affect productivity. Plus, poor packaging or labelling mistakes lead to clients receiving damaged or incorrect food items affecting customer satisfaction and negatively impacting a manufacturer’s brand.

Case Packing Automation

The solution to overcoming labour shortages in case packing is automation. Using dedicating case packing solutions offers businesses significant benefits, including:

- Higher efficiency and the ability to increase your production output

- Improved accuracy, reducing packaging errors.

- Less strain on your already depleted workforce.

Some companies may feel the initial outlay to automate case packing is too high. But with the benefits you receive over the machine’s lifetime, automation more than pays for itself. OMRON

With less staff available, the food production industry needs automation now more than ever. Higher productivity from automating tasks like case packing will be the key to maintaining or scaling output with a reduced workforce.