Automation blog

Green packaging industry: How to achieve sustainable manufacturing

09 February, 2022 Sustainability in the packaging industry is one of the key aspects in fighting the plastic waste issue and ultimately climate change. The challenges that this presents, require flexible and powerful automation technology.

Hanover Displays automates PCBA testing with cobots

31 January, 2022 UK-based Hanover Displays Limited needed a new system for testing printed circuit board assemblies (PCBAs) and selected OMRON TM cobots for the job, supplied and installed by Absolute Robotics, part of the Absolute Automation Group.

Five challenges in High-Mix, Low-Volume (HMLV) packaging and palletizing processes

21 December, 2021 The new product has just left the factory, in a shelf-ready package in the specified mixed ratio to meet customer needs. The packaging has actually been handled by another company: a co-packer. Co-packing can be found in all Fast-Moving Consumer Goods (FMCG) markets, but especially in the higher-priced product segments such as personal care or confectionery, to name a few examples. It is a fast-growing activity to satisfy the consumer demand for more variety.

Productivity Peaks: Moving Maintenance From Preventive to Predictive

17 December, 2021 Maintenance is a vital key to a thriving business, especially in manufacturing where 24/7 plant equipment uptime is often expected as standard. As any established enterprise knows, keeping production lines and systems running optimally requires more than a skilled maintenance team. It also involves careful planning, tight scheduling, constant vigilance, a willingness to change out unworn parts, and a readiness to respond to unplanned events. At least, it used to.

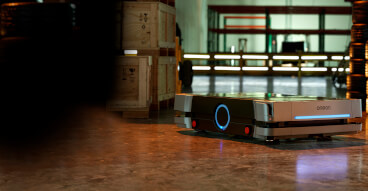

Rethink your Company’s Intralogistics Approach with Autonomous Mobile Robots (AMRs)

09 December, 2021 Intralogistics refers to the management and movement of materials and goods within a facility, and whether it is a warehouse, distribution centre, factory, or another production facility, it can be a significant hurdle to overcome. But by investing significant time and effort into your facility’s intralogistics, you can:

How Automating Tasks like Case Packing is the Logical Response to Record Vacancies

02 December, 2021 The UK is experiencing significant labour shortages across multiple industries. Brexit combined with the pandemic led to total UK job vacancies passing 1 million for the first time on record, and the food industry is one of the hardest-hit sectors. A lack of staff to call upon puts considerable strain on our food supply and creates headaches for employers around the country.Within the food industry, much of the focus has been on the shortage of lorry drivers and how this is causing higher food prices. However, a lack of staff is being felt across the industry in production, fruit/veg picking, packaging, and more.Strict travel restrictions due to Covid combined with Brexit means jobs previously performed by overseas workers remain unfilled. Plus, the pandemic and a break from the usual work cycle lead many people to re-evaluate their profession and look for careers that offer them increased flexibility and autonomy over when and where they work.A significant portion of the food industry vacancy problems is in less desirable positions that are low wage and physically demanding. Fortunately for employers, many of these jobs are ideal candidates for automation. Case packing is a great example of this.

Finished seals in less than 10 seconds: Robotics Integrated Controller ensures harmonious control

24 November, 2021 Trelleborg Livorno has updated a robotic cell for the finishing of polyurethane gaskets for the sustainable wind energy market. The cornerstone of the solution is OMRON's Robotics Integrated Controller that ensures integration and synchronization of all automation components, including robots, logic, motion, safety and user interface.

The Pitfalls of Manual Handling in End of Line Applications and Why Automation Is The Solution

18 November, 2021 No matter the industry you operate in, packaging, managing, and getting your inventory to where it needs to be is a significant headache. Businesses require robust and agile palletising processes that maximise efficiency, eliminate costly errors, and integrate seamlessly within wider workflows.Automating your end of line applications offers a range of tangible business benefits to increase output, reduce costs, and give your company a real competitive advantage.In the past, implementing new automated systems has been seen as too complex a process. The learning curve of integrating an entirely new system has appeared too steep to reach the benefits on the other end.But with new collaborative robotic systems, like the RB1200 Cobot Palletiser from Omron, automating your end of line processes has never been simpler. The RB1200 provides versatile and straightforward solutions for your palletising needs. The plug and play system with intuitive visual software can be configured in minutes to match the product and configuration you require.With advanced automation solutions for end of line applications, your business can simplify stock management and avoid the pitfalls associated with manual handling.Companies that rely on manual handling to stack and transport their goods are doing business on hard mode, making a complex task more difficult. The downsides of utilising manual handling in your end of line processes include:

Digitally Transform your Food Production Line using Smart Pick and Place Robot

17 November, 2021 A once in a generation labour shortage has put the UK food industry in a precarious position. Through a combination of Covid and Brexit, fewer workers being available is placing significant strains on food production and supply chains. A lack of:Delivery driversProduction line workersFruit pickersAbattoir staffAnd other workersHas led to instances of empty supermarket shelves with a growing number of missed food deliveries. Our food supply chains are beginning to feel the bite.

Manual Tasks in Manufacturing: Risky? Expensive? Both!

04 November, 2021 There are fewer people employed in the manufacturing sector now than at any other point in the last 25 years!! According to the Office for National Statistics, the 6- month period between October 2020 and April 2021 saw the lowest level of employment in the manufacturing sector since 1996. Conversely, consumer demand is at an all-time high. The impact of this is acutely felt in the food industry where a severe shortage of workers has led to unprecedented levels of job vacancies..

FasThink optimizes Garnet's intralogistics with mobile robots

02 November, 2021 Garnet relies on FasThink to innovate its logistics and production processes.