Automation blog

Automation adapts to sustainable packaging

16 August, 2022 Have you ever ordered a small item online, and then felt incensed when it arrived in an oversized box packed out with bubble wrap, air-filled cushions or paper inserts?

Flexible Manufacturing Roadshow: Taking the factory of the future across Europe

16 June, 2022 What if you could see, feel and touch the factory of the future? What does it take to realize flexible, efficient, and sustainable production? This is the idea behind OMRON’s unique Flexible Manufacturing Roadshow travelling across Europe this year. The roadshow features exclusive demonstrations of human-machine collaborative solutions not usually seen outside of a factory setting due to their size and scale.

Building the Factory of the Future together

16 June, 2022 As one of the largest business units at OMRON, we aim to further develop the Den Bosch plant to serve the needs in the EMEA region.

Traceability in Automotive: What decision-makers and experts should look out for now

23 May, 2022 From e-mobility to autonomous driving, from skills shortages to digitalization: The automotive industry is undergoing a profound change, marked, for example, by a shift to globalized platforms and standardized vehicle architectures. On the one hand, production is becoming increasingly efficient, but on the other, even a single faulty part can have more far-reaching effects than ever before. Faced with costly recalls, automotive manufacturers are confronted with increasingly complex requirements and stricter specifications. Is the effort of traceability worth it if it means labeling up to 20,000 parts per vehicle? Yes, it is, but powerful reading and verification technologies along with powerful software is needed to make sense of all the data.There are several reasons why manufacturers need to keep accurate records of the parts and components that make up a new car. From a quality perspective, for example, barcode tracking helps to ensure that the right parts are put together. Even more important, however, is the ability to trace each car part back to its original supplier. In the event of a recall or the discovery of a faulty part, manufacturers have to be able to quickly and comprehensively find out where each part came from. This is complemented by information such as batch number, date of manufacture and other important information to identify which vehicles are affected by a defective part. Recommendations and standards from AIAG, VDA, ANSI and ISO specify the details. As the automotive industry globalizes, worldwide production of light vehicles is expected to reach around 96 million units by 2023. This means that even a single faulty part can have an enormous impact, and therefore must be prevented at all costs.

Lights out? Still unlikely with Industry 4.0

21 April, 2022 For many manufacturers, the prospect of a fully automated, human-free factory feels light years away. When, they ask, is the 4th Industrial revolution coming to us and what can we expect? In this blog, we look at the realities of (fully-/semi-)automated manufacturing, what robots can and can’t do, and why the human touch is still (mostly) irreplaceable.

How the RB1200 Cobot Palletiser Can Simplify Your Automation Deployment

13 April, 2022 Greater automation and collaborative robotics (cobots) are the future for many industries, including logistics. Research by BMW found humans and robots work more than well together. In fact, human-robot teams were 85% more productive than working alone.It makes sense. Combining the speed and accuracy of robotics with the flexibility and intuition of humans compounds the benefits from each to build an unbeatable team.With the RB1200 Cobot Palletiser, OMRON, in collaboration with Reeco, is bringing a revolutionary new approach to end of line palletising. Creating an easy, flexible, safe, and compact solution to getting stock palletised and ready for transport.Palletising is a task perfectly suited to automation. The simple yet repetitive and physically demanding process of getting goods stacked leads to complications when performed manually. In 2019/2020, the Health and Safety Executive (HSE) estimated 19% of non-fatal workplace injuries were caused by handling, lifting, and carrying.Plus, given the labour shortages facing the UK and the wider world and the potential for spiralling staff costs, now is the ideal time to get your company less reliant on manual labour.While there are plenty of benefits to automating your palletising processes (greater output and accuracy, reduced labour and operational costs, etc.), its implementation also has challenges.However, with the RB1200 Cobot Palletiser, humans can collaborate with robotics on their terms, implementing a solution that fits their specific needs.

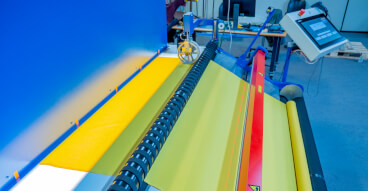

Vadain automates the inspection of curtain fabrics with machine vision

08 April, 2022 Vadain, the market leader in custom curtains in the Netherlands, needed a solution to detect errors as early as possible in kilometers of curtain fabrics. Together with software developers from Sycade, OMRON machine vision technology, and machine builder Eisenkolb, they developed an automated solution to detect and analyze errors in curtain fabrics, making the time-consuming manual inspection process a thing of the past.

Discover How The CP1200 Case Packer Can Transform Your End-of-Line Manufacturing Processes

29 March, 2022 By Stuart Coulton, Market Development Manager, OMRON UK

End of Line Automation: Now is the Time!!

29 March, 2022 By Stuart Coulton, Market Development Manager, OMRON UK

Traditional factories have data needs too

18 March, 2022 The right tools and tech can enable advanced predictive maintenance, bottleneck prevention and optimization. Find out how digitalization is bridging the gap between legacy systems and Industry 4.0.

Fuel for the future: What to look out for in fuel cell production

10 March, 2022 When people talk about sustainable mobility, the first thing that comes to mind is battery-powered e-cars. Fuel cells or direct hydrogen burners are complementary technologies that often fade into the background, yet have a lot to offer when it comes to CO₂ reduction and market options.

Mastering packaging and intralogistics challenges in eCommerce

24 February, 2022 Robot-assisted packaging enables fast and cost-efficient scalability upward and downward to handle swings in demands from the supply chain.

Humans and machine collaborate to meet today’s challenges

23 December, 2019 In Shanghai, labour costs are increasing by 7% every year. With growing shortages in manpower, it is becoming more and more difficult to hire factory operators. On the other hand, companies must consider return on investment and equipment effectiveness when adopting automation solutions in the factory.

Three pillars of successful cobot deployment: safety, quality and flexibility from a single source

04 November, 2019 The use of collaborative robots is expected to increase rapidly in the next years to meet the needs of flexible production lines. To ensure that manufacturing layouts can be easily adapted to changing customer requirements, we recommend teaming up mobile robots and cobots. In addition, companies must consider integrated software apps and vision technology, as well as ensure support and risk assessment.

Agile and clever tailor-made mobile robotics

04 November, 2019 Major German automotive group optimizes efficiency and innovation leadership in material handling with Omron LD mobile robots and a conveyor attachment from cts GmbH.Automobile production and assembly line production have always been closely linked. It was not until Henry Ford began using conveyor belts in his factories in 1913 that the car was able to conquer the world as a mass-produced product. Today, a working day without assembly lines is inconceivable at the BMW factories. The group relies on innovative transport and logistics to increase efficiency and flexibility, to better link work processes, as well as to relieve employees from repetitive and time-consuming tasks. These concepts include Omron LD mobile robots for material transport that deliver a particularly high return on investment (ROI). These autonomous mobile robots are equipped with a conveyor tower - a height-adjustable load handling device, developed by system integrator cts GmbH. The interaction between employees and transport robots at BMW impressively demonstrates how factory harmony can be implemented in the factory of the future.

Top tips for choosing a mobile robot

16 October, 2019 In an age of short product lifecycles and an increasing demand for customised solutions, if you’re a manufacturer, you need to be very agile to remain competitive. For instance, you might need to make products down to a lot size of one as simply and cost-efficiently as in mass production; or to change or update your production line at short notice. One key solution is a greater co-operation between people and machinery, leading to improved efficiency and more flexibility in the design of the production line.

Autonomous bin picking with a collaborative mobile robot

16 October, 2019 Our TM collaborative robot provides a unique solution to easily automate applications such as picking and packing that, traditionally performed by humans, have been challenging to automate. As part of the TM series launch, we also released a mobile-compatible model, which seamlessly integrates into Omron’s LD series autonomous mobile robot. Combined with a 3D vision camera mounted directly onto the collaborative robot, this enables for example e-commerce companies to automate more complex tasks. This includes pick and place of various items onto a tray or container, as well as connecting production processes with the autonomous mobile robots for flexible manufacturing and materials handling.

The power of collaboration between machines, people and teams

01 October, 2019 With today’s rapid advances in technology, the manufacturing sector needs to be increasingly agile, ready to adapt to changing demands. Production lines must be more flexible, so that they can cope with shorter production runs, more varied products and tight deadlines. So how can manufacturers address these challenges? The solution lies in more advanced, interconnected and intelligent systems that can be programmed to handle a range of tasks.

Mobile robots speed production at new ‘smart factory’

26 September, 2019 Showcasing flexible production in real life, a new ‘Smart Factory’ in Norway uses a variety of robots in a system developed and implemented by system integrator Intek Engineering.