Professional help for personal care: Putting a cobot to work

Published on 09 July, 2021 in Flexible Manufacturing

- 0:00 - Professional help for personal care: putting a cobot to work

Meeting the challenge

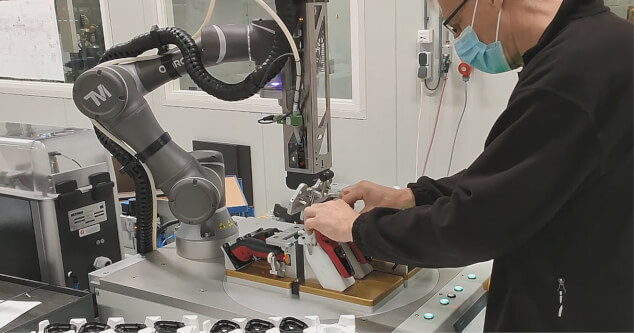

That task: tightening the final screw into personal grooming device; simple enough, you might think. But the intricate process is something that takes great care, accuracy and attention to detail, and involves differing form factors and models, with differing placements of screws per model, which is why it’s generally finalised by hand.Professional solutions

“The customer approached us to see if it was possible to bring a collaborative robot in to help the operator,” Barry Oorbeek, Key Account Manager Industry Solutions at OMRON Benelux explains. The solution design phase involved a thorough audit of needs: “Omron Safety Services Europe (OSSE) first conducted a machine risk analysis, then a Sistema calculation, to define the requirement specifications for the system integrator,” says Barry. “From here we were able to prioritise and plan for the commissioning phase of the project.Selection & setup

“In the setup phase, we used the intuitive plug&play software to establish virtual ‘safety fences’ prior to installation. This set clear boundaries around the cobot, to limit its range of movement to its specific area of operation.” This ensured complete predictability, so that the operator had a confident understanding of where the cobot would be, and what it would be doing, at all times.

Safety first

For the customer, the key criterion was of course safety, since the cobot would be working in close proximity with a human operator. From the various options suited for the task, they chose the OMRON TM5-700, a unit built for quick start-ups, rapid changeovers and of course, inherent safety, as Barry explains. “From the points highlighted in the machine risk analysis, OSSE then conducted extensive force- and pressure-testing, going through each potential risk point, establishing the maximum permissible pressure, and confirming that the cobot was able to instantly and accurately sense the results of its actions.”Rapid start-up, intuitive operation

An intuitive human-machine interface within the machine controller gives full overview and control of the cobot, which is designed for ease of use. Operators need only 5 minutes’ instruction before starting to work with the system, which was engineered to keep pace with the speed of the manual production line.Ideal human/cobot mix

“This system goes a long way to solve a very common problem in production lines,” says Barry Oorbeek. “Repetitive tasks done by hand can suffer from quality variation over time. With this solution, the customer has the ideal combination—the flexibility of an operator to handle the high diversity of components, with the accuracy and sensitivity of the OMRON cobot to perform the repetitive screw-fastening process.”So why not fully automate?

The customer in this case already has a large installed base of OMRON robots in place, with some automated screwdriving in automated lines. But this particular workstation is used for a variety of form factors and end-products, so it was decided to bring a cobot on board, since there may be multiple changes per day of the product that’s being finalised. “OMRON cobots are designed to be supremely flexible, both in the way they are simple to program, and in the way that they can be used. Here for instance, the customer can achieve single-minute exchange of dies (SMED), moving from one product type to another extremely quickly.”The end result?

“A delighted customer,” Barry concludes proudly. “Their process quality has improved, and they have an integrated solution that was quickly verified and validated.” This OMRON customer is currently investigating the use of OMRON cobots in other areas of its production facilities.