Remote Connectivity to Production Assets

Being digital is about removing the reliance on physical presence. Being able to monitor and access manufacturing assets virtually is one of the main drivers of investment in industrial digitalisation.

On demand connection

In case of any alarm or notification in a machine, a technical person can remotely connect to the machine and fix the error or get more information to provide a fast and effective solution to fix the problem reducing machine downtime.

Security first

Managing the risks of remote connectivity. Granularity approach in User management and device management allow system administrator to define exactly who can access to which device and how long access is enabled. It is also automatically traced the activity done and when.

Download our leaflets “Smart maintenance ideas and solutions’’ to learn more

Back to Smart Maintenance

Maintenance is a vital to assuring 24/7 operations. Even the failure of a single component can have a massive impact on operations, while energy and maintenance expenses are a major part of the lifecycle costs of automatic machines

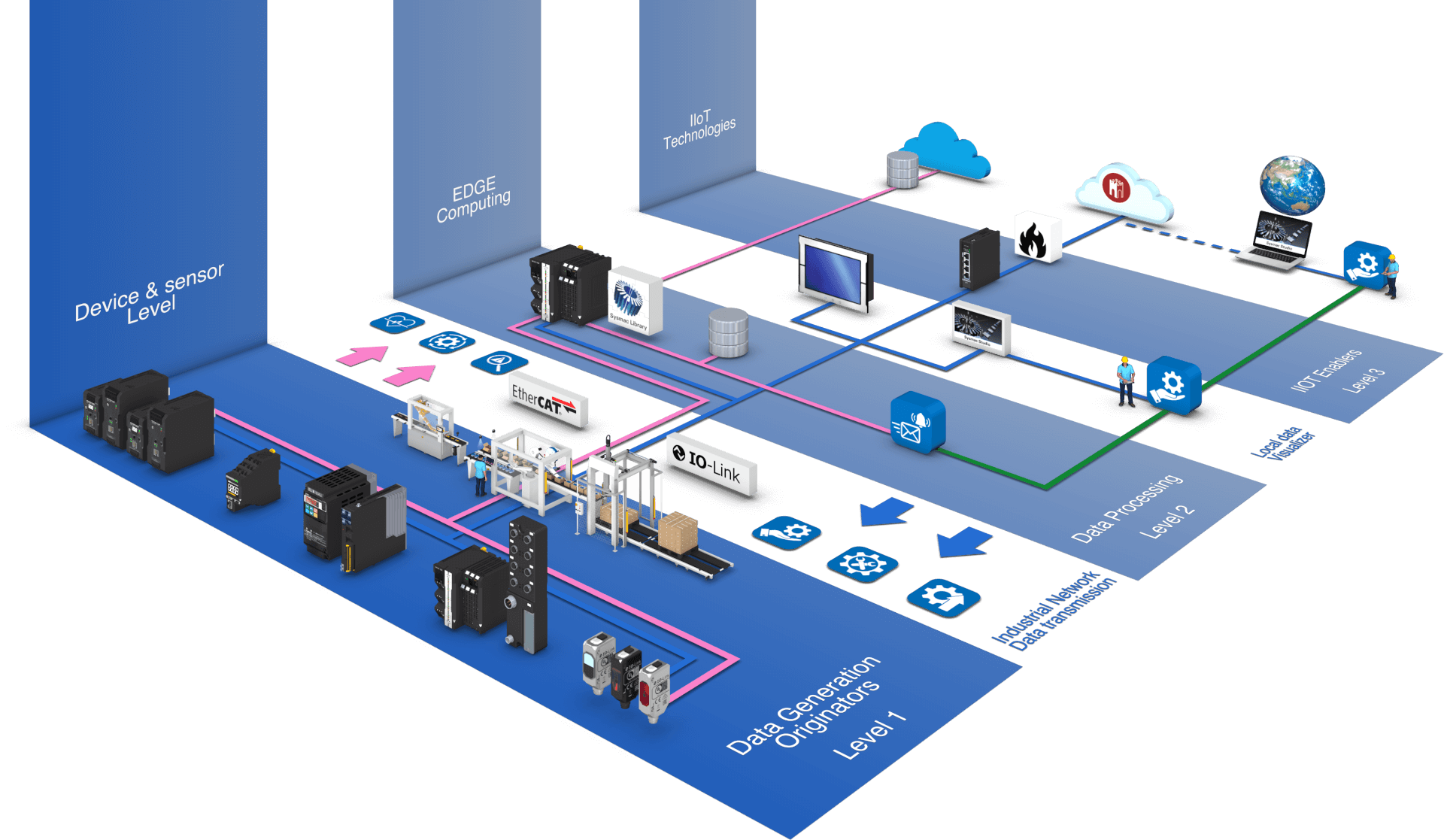

LEVEL 1: Generate self-explanatory Maintenance information

OMRON components, sensors and actuators are designed to provide Realtime system health information.

LEVEL 2: Elaborate Maintenance Data and information at the edge

Elaboration is done at machine level for quick reaction time and alerts.