TM

Collaborative robots assembly, packing, inspection and logistics

- Fast and simple programming

- Built-in intelligent vision

- This product complies with the combined scope of ISO 10218-1:2011 and ISO/TS-15066

- Fast changeover using TMvision and Landmark

- Advanced collaborative control

- External Camera Support: Optional software to support 2 additional GigE vision cameras

-

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!

02:23

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!The Collaborative Robot

Omron TM12 cobot automates booklet feeding for Kraus Maschinenbau

Cobots streamline processes in medtech and packaging industry

Features

Faster set-up with built-in vision

-

Meet our collaborative robot

For over 85 years, Omron has helped perfect the art of machines that help humans. Now, we introduce the machines specifically built to work with people - meet the Omron TM Collaborative Robot Series!

02:23

Quick Start-up and changeover

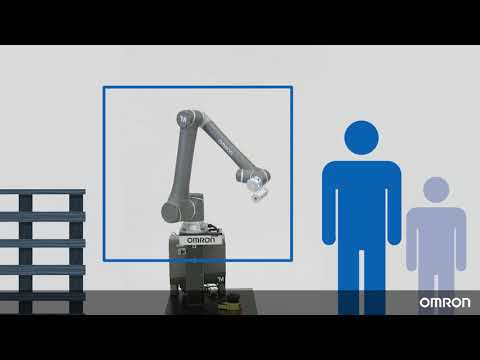

Safety in collaborative applications

Cobot Safety Expert article

Cobot and flexible production - Future-proofing SMEs?

Many countries in Europe, such as the UK and Germany are likely to experience serious labour shortages over the coming decade, especially in relation to technical specialists. At the same time, product lifecycles are becoming shorter. Despite this, small and medium-sized enterprises (SMEs) might be reluctant to invest in additional automation. However, collaborative robots (cobots) are easy to set up and offer a quick and cost-effective solution. They can increase the flexibility, quality and speed of production and enable companies to respond rapidly to changing market conditions. Omron’s TM series of cobots are a good example of this versatility.

Models

TM 5 – 700

- Reach (mm): 700

- Maximum payload (kg): 6

- Maximum speed (m/s): 1.1

TM 5 – 900

- Reach (mm): 900

- Maximum payload (kg): 4

- Maximum speed (m/s): 1.4

TM12

- Reach (mm): 1300

- Maximum payload (kg): 12

- Maximum speed (m/s): 1.3

TM14

- Reach (mm): 1100

- Maximum payload (kg): 14

- Maximum speed (m/s): 1.1

TM16

- Reach (mm): 900

- Maximum payload (kg): 16

- Maximum speed (m/s): 1.1

TM20

- Reach (mm): 1300

- Maximum payload (kg): 20

- Maximum speed (m/s): 1.3

Specifications & ordering info

| Product | Hardware version | Payload | Reach | PROFINET communication | EtherNet/IP communication | Vision | Power supply type | SEMI S2 certified | Food grade grease | SIL according to IEC 61508 | Performance level according to EN ISO 13849-1 | Cable length | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-700, 12 m cable, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-700, 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | No | No | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-700, HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-900, 12 m cable, HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5-900, 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 4 kg | 900 mm | No | No | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | Yes | Yes | Yes | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5-900, HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-700 (model without camera), 12 m cable, HW3.2 |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-700 (model without camera), 12 m cable, HW3.2, PROFINET & EtherNet/IP |

|

|

|

3.2 | 6 kg | 700 mm | No | No | No | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, Food Grade Grease |

|

|

|

3.2 | 6 kg | 700 mm | Yes | Yes | No | AC | No | Yes | 2 | Level d | 3 m | Bundle, Cobot, TM5X-700 (model without camera), HW3.2, PROFINET & EtherNet/IP, Food Grade Grease |

|

|

|

3.2 | 4 kg | 900 mm | No | No | No | AC | No | No | 2 | Level d | 3 m | Bundle, Cobot, TM5X-900 (model without camera), HW3.2 |

|

|

|

3.2 | 4 kg | 900 mm | No | No | No | AC | No | No | 2 | Level d | 12 m | Bundle, Cobot, TM5X-900 (model without camera), 12 m cable, HW3.2 |

|

We’re Here to Help

Got a question? Our specialists are ready to assist you every step of the way.

Contact me TM

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for TM

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadCustomer Cases

Cobots give gear manufacturer a competitive production edge

Danish gear manufacturer, Fischer Gears, has boosted the competitiveness of its production process - especially on larger series – by installing two OMRON TM robots. The collaborative robots (cobots) free experienced employees to focus on more value-adding tasks.

Innovative cobot application improves safety at Leica Geosystems

Collaborative robot automates tray handling and improves safety and ergonomics in a hazardous working area.

Collaborative robots enhance productivity at CLECA

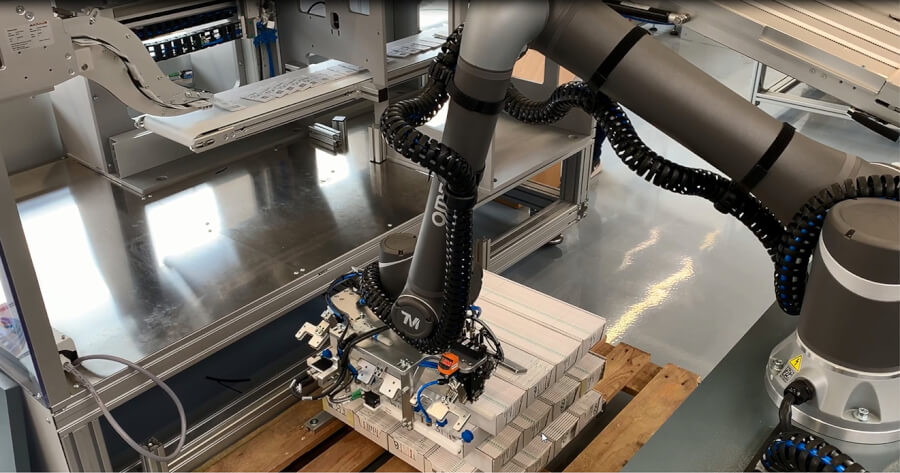

Palletizing process automated with OMRON TM12 cobots

Palletising solution from Reitec meets the needs of FMCG customers

OMRON and Reitec join forces to create the new RC-1 cobot palletiser solution

Agile cobot palletiser from Reeco Automation

60% smaller footprint and costing up to 50% less compared to conventional robot palletisers

Traceability 4.0 through streamlined package labelling with cobots

Collaborative robot carries out intelligent labelling on different product formats - reducing downtime due to format changes by up to 70% - in a solution developed by Bluengineering for Gruppo Romani in Italy.

Cisel ensures traceability, safety and quality by testing printed circuit boards with a cobot

Cisel is an Italian company that specialises in the design and production of flexible printed circuit boards (PCBs) for the automotive, civil engineering and manufacturing industries. The company recently chose an OMRON TM5 collaborative robot (cobot) to automate the electrical testing of boards used in the power steering system of a leading automotive manufacturer.

Cobot ensures precise assembly of magnets for LITMAT’s drain plugs

Collaborative robots (cobots) are being used more and more extensively, in a range of different industries and across a wide variety of applications. They can make a significant difference to the efficiency and productivity of the production cycle. One company that is enjoying such benefits is LITMAT SpA.

Unika makes Landmark decision to bring quality levels to new heights

OMRON TM cobots with integrated vision system eliminate human error, increase production efficiency.

Applications

Solutions

Omron Mobile Manipulator Solution

Combining a collaborative robot and a mobile robot, the Mobile Manipulator hybrid concept, or MoMa, is a new breed of robot with all the benefits and none of the limitations of these technologies.

Cobot Palletizing Solution

Easy to install and configure palletizing solutions. OMRON and its partners offer a complete palletizing solution. Integrating cobot, PLC & HMI with the complete sequencing performed from the PLC.

Tutorial Videos

-

Omron Collaborative can draw!

Omron Collaborative Robot can be used for a variety of purposes and numerous applications especially machine tending, loading and unloading, assembling, gluing, testing, and soldering! On this video you can see just one of them, drawing Omron’s logo with a pen on the blackboard! Just amazing Omron Collaborative Robots can do.

00:31

Omron Collaborative can draw!

Omron Collaborative Robot can be used for a variety of purposes and numerous applications especially machine tending, loading and unloading, assembling, gluing, testing, and soldering! On this video you can see just one of them, drawing Omron’s logo with a pen on the blackboard! Just amazing Omron Collaborative Robots can do.

-

Omron Collaborative Robots Tutorial 1 - Unboxing and Initial Set Up

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show you how to unbox the Cobot and do the initial set up. There are several Cobot in the TM Series depending on your needs. Here we will be using the TM5 – 700 models to explain the common features.

06:34

Omron Collaborative Robots Tutorial 1 - Unboxing and Initial Set Up

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show you how to unbox the Cobot and do the initial set up. There are several Cobot in the TM Series depending on your needs. Here we will be using the TM5 – 700 models to explain the common features.

-

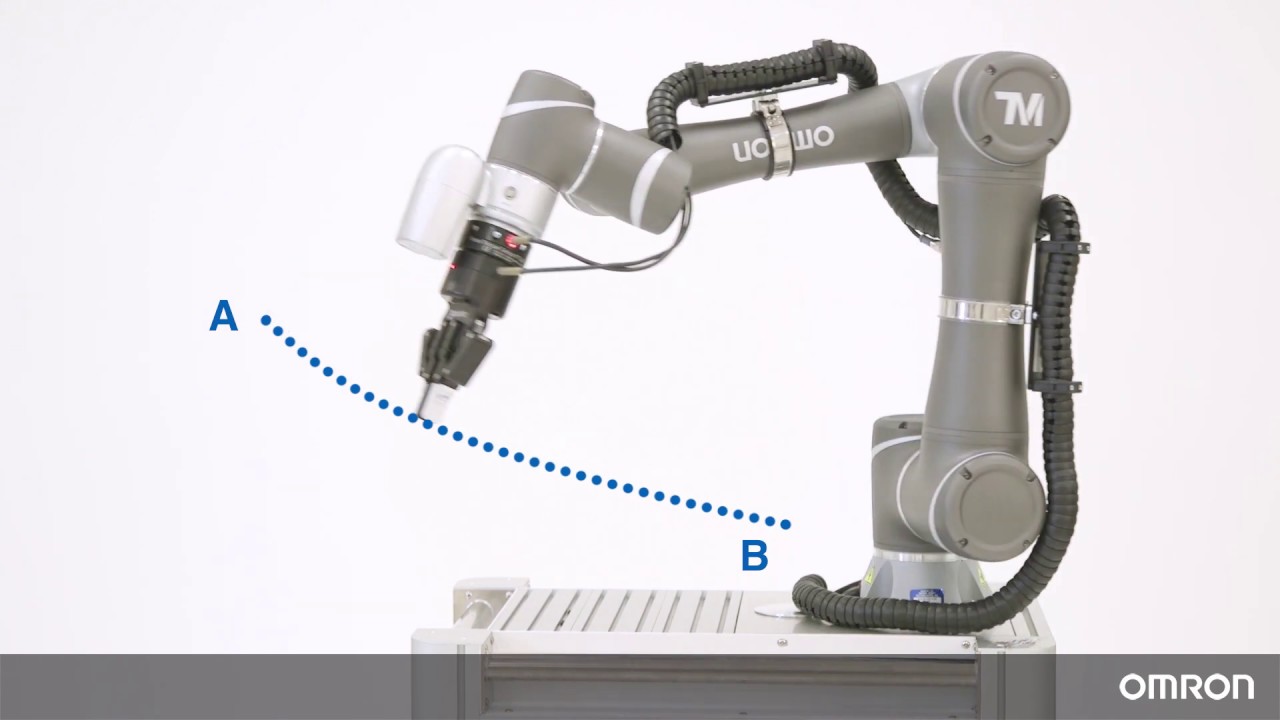

Omron Collaborative Robots Tutorial 2 – Programming the Basic Motions

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we would like to show you the basics of how to make the Cobot move.

06:40

Omron Collaborative Robots Tutorial 2 – Programming the Basic Motions

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we would like to show you the basics of how to make the Cobot move.

-

Omron Collaborative Robots Tutorial 3 – How to Program Using Flow Chart Software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, you can learn how to use the software, called “TMflow,” to program the Cobots. TMflow has an intuitive user interface that allows you to easily create a program using flowcharts.

05:23

Omron Collaborative Robots Tutorial 3 – How to Program Using Flow Chart Software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, you can learn how to use the software, called “TMflow,” to program the Cobots. TMflow has an intuitive user interface that allows you to easily create a program using flowcharts.

-

Omron Collaborative Robots Tutorial 4 – How to Attach a Gripper to the Cobot

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to use grippers with your Cobot.

04:37

Omron Collaborative Robots Tutorial 4 – How to Attach a Gripper to the Cobot

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to use grippers with your Cobot.

-

Omron Collaborative Robots Tutorial 5 – Vision Calibration and Vision Node

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to start using the built-in camera and the integrated vision system for your applications. One of the biggest advantages of this Cobot is that you can rapidly create an application in which you want the Cobot to see and recognize the object that it is working on. You do not need additional lens nor lights.

05:13

Omron Collaborative Robots Tutorial 5 – Vision Calibration and Vision Node

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we will show you how to start using the built-in camera and the integrated vision system for your applications. One of the biggest advantages of this Cobot is that you can rapidly create an application in which you want the Cobot to see and recognize the object that it is working on. You do not need additional lens nor lights.

-

Omron Collaborative Robots Tutorial 6 – Pick and Place Using Vision

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we finished the vision calibration and explored some of the vision tasks. So now we are ready to start creating an application that utilizes the camera and the vision system. We will pick up a cylinder from this hole and place it here.

06:46

Omron Collaborative Robots Tutorial 6 – Pick and Place Using Vision

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video, we finished the vision calibration and explored some of the vision tasks. So now we are ready to start creating an application that utilizes the camera and the vision system. We will pick up a cylinder from this hole and place it here.

-

Omron Collaborative Robots Tutorial 7 – Updating TMFlow software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show how to update the TMFlow software. We constantly have software updates, so make sure you update Collaborative Robots software so that you can utilize the newest features.

04:49

Omron Collaborative Robots Tutorial 7 – Updating TMFlow software

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will show how to update the TMFlow software. We constantly have software updates, so make sure you update Collaborative Robots software so that you can utilize the newest features.

-

Omron Collaborative Robots Tutorial 8 – Communication via ModBus

Meet the Omron Collaborative Robot Series to assist your automation needs. The Omron Collaborative Robots is capable of different types of communications. On this video we will focus on using ModBus TCP communication in TMFlow software.

07:15

Omron Collaborative Robots Tutorial 8 – Communication via ModBus

Meet the Omron Collaborative Robot Series to assist your automation needs. The Omron Collaborative Robots is capable of different types of communications. On this video we will focus on using ModBus TCP communication in TMFlow software.

-

Omron Collaborative Robots Tutorial 9 – Advanced Motion Methods

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will discuss the different types of advanced motions that Omron’s Collaborative Robots can achieve. We will focus on some of the different types of motions that our Cobots can use to fit in your applications.

04:32

Omron Collaborative Robots Tutorial 9 – Advanced Motion Methods

Meet the Omron Collaborative Robot Series to assist your automation needs. In this video we will discuss the different types of advanced motions that Omron’s Collaborative Robots can achieve. We will focus on some of the different types of motions that our Cobots can use to fit in your applications.

-

Collaborative Robot Safety Tutorial - Video 1

Watch this safety video to learn about Omron's Collaborative Robot safety features. Safety Standards & Safety Functions, Emergency Stop & Protective Stop and Safety Output Functions will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

05:50

Collaborative Robot Safety Tutorial - Video 1

Watch this safety video to learn about Omron's Collaborative Robot safety features. Safety Standards & Safety Functions, Emergency Stop & Protective Stop and Safety Output Functions will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

-

Collaborative Robot Safety Tutorial - Video 2

Watch this second part safety video to learn even more about Omron's Collaborative Robot safety features. Intuitive Safety Parameter Setting, Cartesian Safety Limit and Omron Risk Assessment Service will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.

06:55

Collaborative Robot Safety Tutorial - Video 2

Watch this second part safety video to learn even more about Omron's Collaborative Robot safety features. Intuitive Safety Parameter Setting, Cartesian Safety Limit and Omron Risk Assessment Service will be discussed. Note: this video is intended to be an introductory guide, for futher important information on safety please refer to the other available safety documentation.Downloads

Services

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact me TM

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for TM

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download