Avoiding product recalls in the Food & Beverage industry

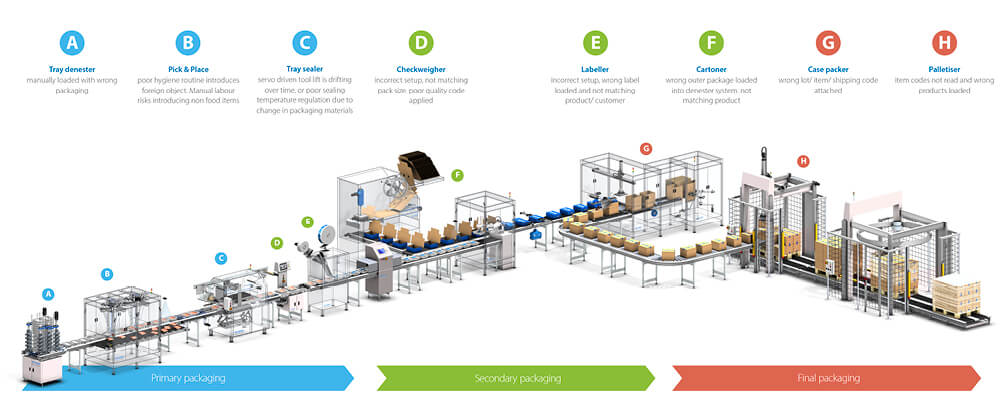

... the dynamic modern production facility includes numerous areas where genuine mistakes can occur.

As the demands raised by society grow, it means on the one hand producers having to cope with increased product range diversification and new materials/ formats whilst continuously striving to maintain consumer confidence and reduce costs.

Manufacturers are having to cope with:

- Fluctuating market demands - means varying production runs.

- Production flexibility [packaging size / shape / customization) - packaging, including “flash” packs have to be correct and changed accordingly.

- Shorter Batch production (product/ quantity related) - quick changeover required.

- Complexity - multipacks, country of origin, specific retailer demands all place pressure on the producer.

Product recalls are happening every week of the year, and increasing in number. There are many causes of a faulty product being shipped into the supply chain, and the correct implementation of automation can reduce the risk of this happening. These are just some of the areas where Omron can assist:

- Poor sealing quality.

- Right item, right quality.

- Labelling issue (Correct product/ label match).

- Marketing "Flash" pack labels applied.

- Printed code quality checking.

- Wrong label relating to ingredients or allergens, use by/ sell by date code incorrect.

Benefits to the producer of avoiding recalls:

- Protected brand value.

- Maintained retailer and consumer confidence.

- Minimised production disruption.

These are some of the critical points where within a modern and dynamic production environment, genuine mistakes can occur.

Vision Inspection

- Product quality verification

- Packaging quality inspection

- Label/presence quality

- Code verification

Robotics

- Hygienic design ensures no foreign material enters product or packaging

- Reduces manual labour and ensures accuracy

- Low cost of ownership

- Integrated into overall automation platform

Components & Measurement sensors

- Wide range of simple to complex solutions

- Hygienic design models

- Multiple packaging materials detection ie. Foils, caps, cartons, transparent, labels etc.

- Displacement, profile and high accuracy measurement models

Database connectivity

- Record quality inspection and production intelligence

- Provide Traceability through the production process

- Ensure regulation compliance

- Store and analyse data for improvement programs

- Provide line and machine data for predictive maintenance

Temperature controllers

- Ensures correct sealing of packaged goods i.e. Seal integrity

- Reduces waste and changeover time

- Maintains production line conditions