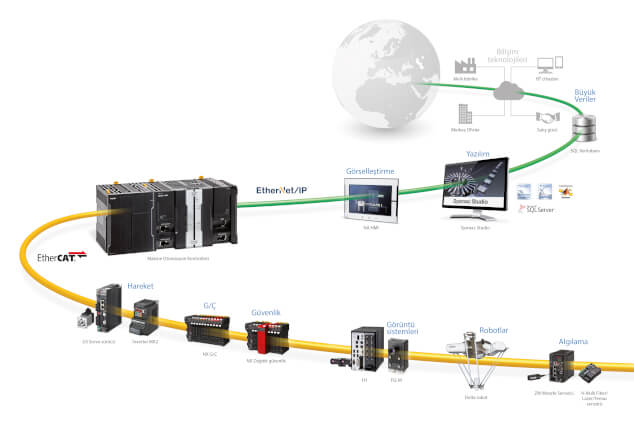

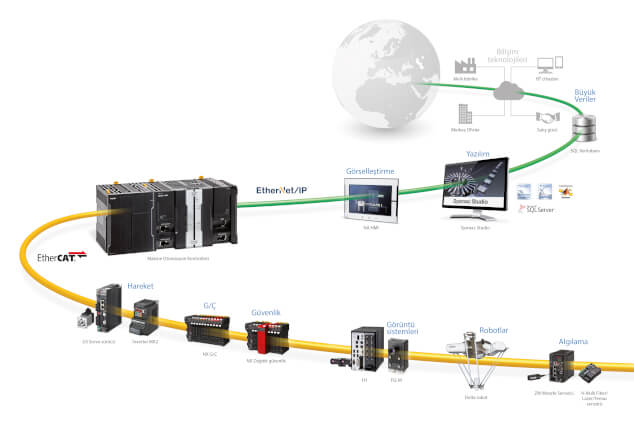

Integrated data control, motion control and machine vision for next-generation automotive production line

Published on 24 April, 2020 in Industry 4.0

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadWe are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFill in your details below and get direct access to content on this page

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadYou now have access to Integrated data control, motion control and machine vision for next-generation automotive production line

A confirmation email has been sent to

Continue to pagePlease log in or get direct access to download this document

Published on 24 April, 2020 in Industry 4.0