i4H

Gain more out of production with a higher payload and faster cycle time

Achieve more by seamlessly integrating the robust i4H into your production line today. With an updated robust design, the i4H can achieve a more meaningful and efficient production for your factory needs.

- 15 kg payload capacity

- 650 mm, 750 mm, and 850mm reach options with floor, wall and ceiling mounting options

- Robot Integrated Controller NJ-R with EtherCAT connectivity

- Stand Alone Ethernet models

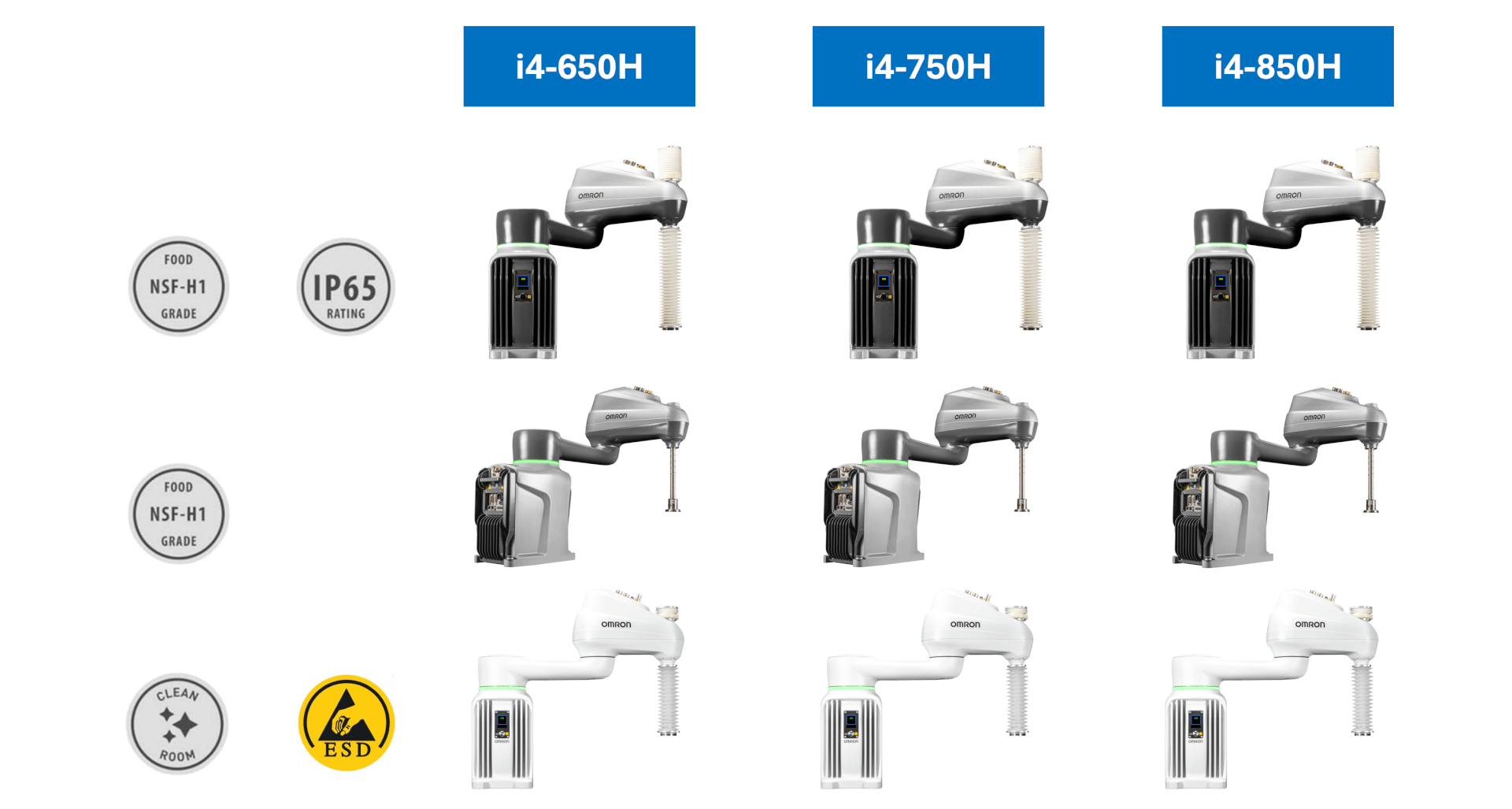

- Options: IP65, Food Grade, ESD and Clean Room

- Fast cycle time with an unprecedented range of movement and repeatability

- Advanced and robust industrial design

- Lowest total cost of ownership

- Optimize your line with maximum uptime by means of interactive maintenance alarms and an RGB dome light

Accessories

Ordering information

| Apperance | Type | Name/Specifications | Order code |

|---|---|---|---|

|

Robot Integrated Controller | 16 motion axis, up to 8 robots control | NJ501-R300 |

| 32 motion axis, up to 8 robots control | NJ501-R400 | ||

| 64 motion axis, up to 8 robots control | NJ501-R500 | ||

|

Pendant | T20 Pendant with 10 m Cable | 10046-010 |

| T20 Pendant-Jumper Plug | 10048-000 | ||

| T20 Pendant Wall Bracket | 10079-000 | ||

| T20 Adapter Cable, 3 m | 10051-003 | ||

|

Vision Controller | IPC Application Controller | AC1-152000 |

|

Camera | GigE PoE, 1602 x 1202 pixels, 60 fps, Monochrome, CMOS (1/1.8-inch equivalent), camera cables included (10 m) | 24114-250 |

| GigE PoE, 1602 x 1202 pixels, 60 fps, Color, CMOS (1/1.8-inch equivalent), camera cables included (10 m) | 24114-251 | ||

| GigE PoE, 2048 x 2048 pixels, 25 fps, Monochrome, CMOS (1-inch equivalent), camera cables included (10 m) | 24114-300 | ||

| GigE PoE, 2048 x 2048 pixels, 25 fps, Color, CMOS (1-inch equivalent), camera cables included (10 m) | 24114-301 | ||

| Belt Encoder (Conveyor-Tracking) |

Encoder Kit IP65 | 09742-001 | |

| Y-Adapter Cable, 3 m | 09443-000 | ||

| Encoder Extension Cable, 5 m | 09446-050 | ||

| SCEX-BELT,Y-Adapter Cable, 0.5 m | 09550-000 | ||

| XBELTIO Cable, 0.6 m | 13463-000 | ||

| Additional I/O Options | IO Blox (connect to robot), 8 inputs/8 outputs, cables included (0.3 m) | 90356-30200 | |

| IO Block (connect to previous IO Blox), 8 inputs/8 outputs, cables included (0.3 m) | 90356-30100 | ||

| IO Blox-to-robot Cable, 3 m | 04677-030 | ||

| IO Blox-to-IO Blox Cable, 3 m | 04679-030 | ||

| IO Blox-to-IO Blox Cable, 0.3 m | 04679-003 | ||

| XIO Termination Block, 12 inputs/8 outputs, cables included (1.8 m) | 90356-40100 | ||

| XDIO Termination Block, 50 pin, cables included (2 m) | 09747-000 | ||

|

Front Panel | Front Panel with 3 m cable | 90356-10358 |

| Front Panel Cable, 3 m | 10356-10500 | ||

| Power Supply/Cable | AC Power Cable, 5 m | 04118-000 | |

| 24 VDC Power Cable, 5 m | 04120-000 | ||

| 24 VDC, 6.5 A, 150 W (Front Mounting), Power Supply | S8FS-G15024C

2

Refer to the Switch Mode Power Supply Datasheet

(Cat.No.T207) for details. |

||

| 24 VDC, 6.5 A, 150 W (DIN-Rail Mounting), Power Supply | S8FS-G15024CD

2

Refer to the Switch Mode Power Supply Datasheet

(Cat.No.T207) for details. |

||

| 1394 Cable, 4.5 m | 13632-045 | ||

| eAIB XSYSTEM Cable Assembly, 1.8 m | 13323-000 | ||

| DB9 Splitter, 0.3 m | 00411-000 | ||

| eAIB XSYS Cable, 4.5 m | 11585-000 | ||

| Ethernet Cable | XS6W-6LSZH8SS

2

Refer

to the Industrial Ethernet Cables Catalog (Cat.No.G019) for details. |

||

| Industrial Switching Hubs | W4S1-05C

2

Refer

to the Industrial Switching Hubs Catalog (Cat.No.V227) for details. |

||

| Solenoid Valve Kit | eCobra robots (600, 800, 800 Inverted) | 02853-000 | |

| Cable Seal Kit | Hornet 565 IP65/67, Quattro 650HS IP65/67, Quattro 800HS IP65/67 | 08765-000 | |

| Quattro 650HS Standard, Quattro 800HS Standard | 09564-000 | ||

| eCobra 800 IP65/67 | 04813-000 | ||

| eCobra 800 Inverted IP65 | 09073-000 | ||

|

ACE License | Automation Control Environment (for ACE 4.x) | Please download it from following URL: http://www.adept.com/Robots-Tool |

| ACE PackXpert (for ACE 4.x) | 20409-000 | ||

| ACE Sight Vision Software (for ACE 4.x) | 20410-000 | ||

| ACE PackXpert with ACE Sight Vision (for ACE 4.x) This license contains an ACE PackXpert license and an ACE Sight license. |

20433-000 | ||

|

Related Products | Machine Automation Controller NX/NY/NJ Series | NX/NY/NJ

2

Refer to the Sysmac Catalog (Cat.No.P072)

for details. |

| Automation Software Sysmac Studio | SYSMAC-SE2

2

Refer to the Sysmac Catalog (Cat.No.P072)

for details. |

||

| Collection of software functional componentsSysmac LibraryAdept Robot Control Library | SYSMAC-XR009

2

Refer

to the Sysmac Library Catalog (Cat.No.P106) for details. |

||

Contact your Omron representative for lenses, lights, and licenses.

Sysmac Library

The Sysmac Library is a collection of software functional components that can be used in programs

for the NX/NY/NJ Machine Automation Controllers.Please download it from following URL and install to Sysmac Studio Automation Software.http://www.ia.omron.com/sysmac_library/The Adept Robot Control Library allows you to control Delta, Articulated and SCARA robots manufactured

by Omron Adept Technologies Inc. from the NX/NY/NJ Machine Automation Controller by using the same

instructions and programming methods.

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact me i4H

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for i4H

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

Download

-

OMRON’s i4H SCARA Robot Series

Introducing the i4H, OMRON’s newest SCARA robot Achieve more by seamlessly integrating the robust i4H into your production line today. Unique features enable OMRON’s latest SCARA line to meet today’s demands of mass customization. It also allows manufacturers to produce high mixes of products at low volume which provide a wider array of goods to people. Key features −15 kg payload capacity. − 650, 750, 850mm reach options − Standard & Long Quill lengths − Visual display on base − Health lighting indicators For more information about the OMRON’s i4H SCARA Robot visit our website:

02:00

OMRON’s i4H SCARA Robot Series

Introducing the i4H, OMRON’s newest SCARA robot Achieve more by seamlessly integrating the robust i4H into your production line today. Unique features enable OMRON’s latest SCARA line to meet today’s demands of mass customization. It also allows manufacturers to produce high mixes of products at low volume which provide a wider array of goods to people. Key features −15 kg payload capacity. − 650, 750, 850mm reach options − Standard & Long Quill lengths − Visual display on base − Health lighting indicators For more information about the OMRON’s i4H SCARA Robot visit our website:

Experience our new i4H line of SCARA robots

Models

i4H-650

- Reach: 650mm

- Max. payload: 15 kg

- Quill length: 210 / 410mm

- IP Class: Standard IP20

- Blended Burst cycle: 0.37

- Repeatability (mm): XY ±0.015 / Z ±0.01 / Theta ±0.005

- Mount: The i4H can be mounted to the floor, wall, or inverted

- Different models for EtherCAT and/or Ethernet connectivity

- Options: IP65, Food Grade, ESD and Clean Room

i4H-750

- Reach: 750mm

- Max. payload: 15 kg

- Quill length: 210 / 410mm

- IP Class: Standard IP20

- Blended Burst cycle: 0.37

- Repeatability (mm): XY ±0.025 / Z ±0.01 / Theta ±0.005

- Mount: The i4H can be mounted to the floor, wall, or inverted

- Different models for EtherCAT and/or Ethernet connectivity

- Options: IP65, Food Grade, ESD and Clean Room

i4H-850

- Reach: 850mm

- Max. payload: 15 kg

- Quill length: 210 / 410mm

- IP Class: Standard IP20

- Blended Burst cycle: 0.37

- Repeatability (mm): XY ±0.025 / Z ±0.01 / Theta ±0.005

- Mount: The i4H can be mounted to the floor, wall, or inverted

- Different models for EtherCAT and/or Ethernet connectivity

- Options: IP65, Food Grade, ESD and Clean Room

Feature

Heavier payload

Maximize Uptime

- First ever on-board display for troubleshooting, maintenance and visual inspections

- World’s first robot health lighting indicator

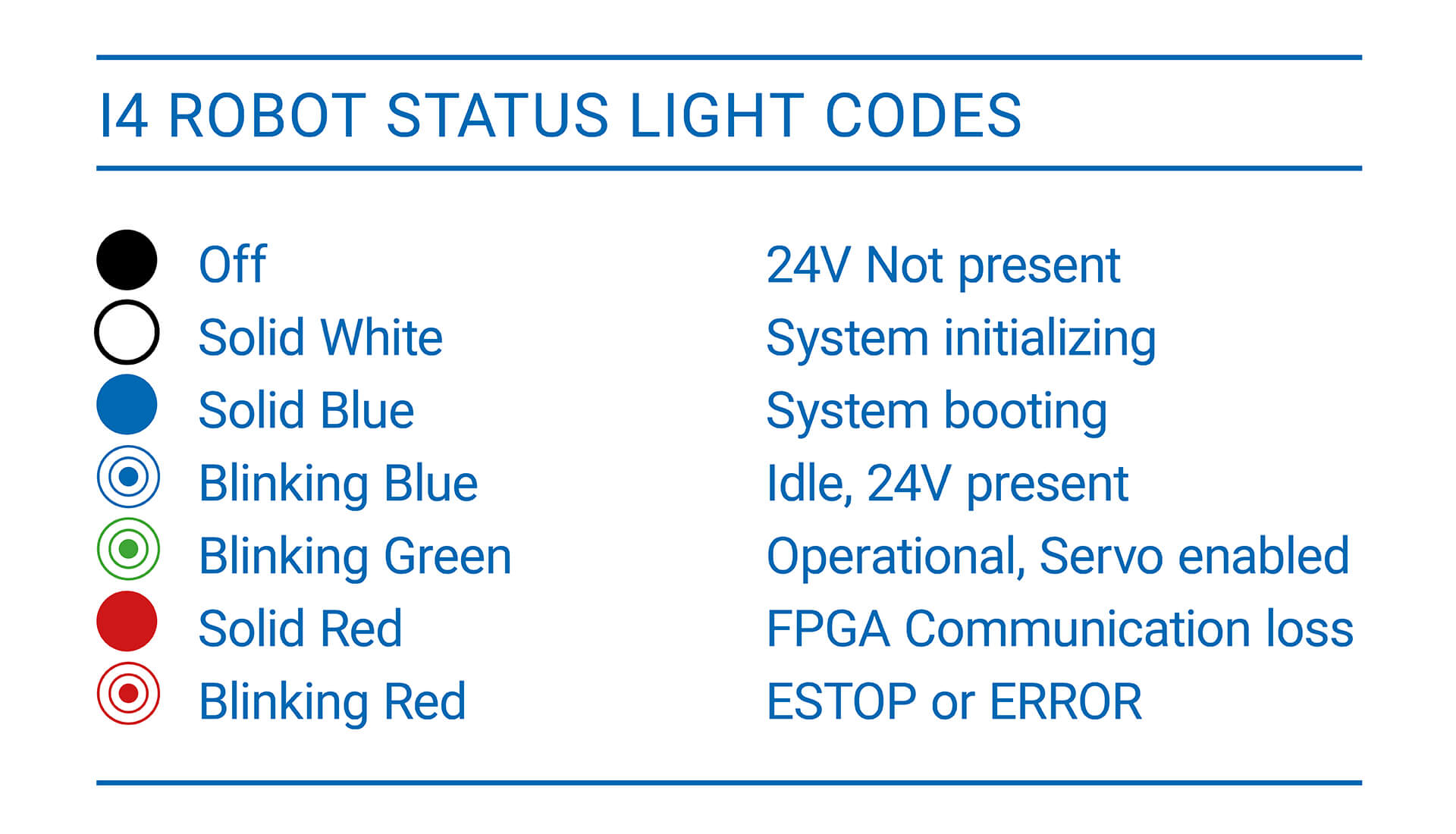

RGB dome light for better diagnoses

- Off

- Solid White

- Solid Blue

- Blinking Blue

- Blinking Green

- Solid Red

- Blinking Red

Industrial Connectivity

ESD Certification

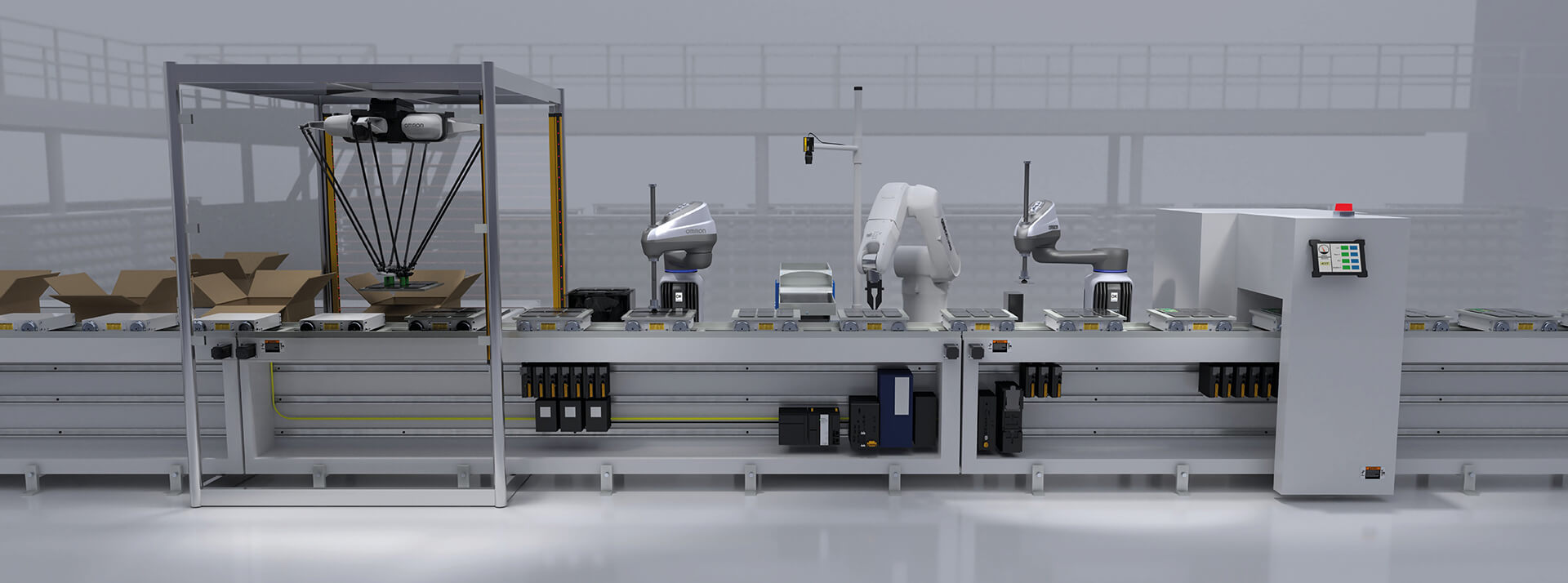

Automate your production line with i4H robots

Specifications & ordering info

| Product | Payload | Reach | Z-Stroke | Robot controller | Degree of protection (IP) | Food grade grease | ESD protection | Suitable for pedestal/floor mounting | Suitable for wall mounting | Suitable for ceiling mounting | EtherCAT communication | PROFINET communication | TCP/IP communication | RS232 communication | Vision | Conveyor tracking | PackXpert | Number of I/O-Blox | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

15 kg | 650 mm | 210 mm | Not required | IP20 | No | No | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 210 mm Zaxis, Table Mount, IP20, iCS-ENET |

|

|

|

15 kg | 650 mm | 410 mm | Not required | IP20 | No | No | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 410 mm Zaxis, Table Mount, IP20, iCS-ENET |

|

|

|

15 kg | 650 mm | 210 mm | Not required | IP20 | No | Yes | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 210 mm Zaxis, Table Mount, CR/ESD, iCS-ENET |

|

|

|

15 kg | 650 mm | 410 mm | Not required | IP20 | No | Yes | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 410 mm Zaxis, Table Mount, CR/ESD, iCS-ENET |

|

|

|

15 kg | 650 mm | 210 mm | Not required | IP65 | Yes | No | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 210 mm Zaxis, Table Mount, IP65+H1 Grease, iCS-ENET |

|

|

|

15 kg | 650 mm | 410 mm | Not required | IP65 | Yes | No | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 410 mm Zaxis, Table Mount, IP65+H1 Grease, iCS-ENET |

|

|

|

15 kg | 650 mm | 210 mm | Not required | IP20 | Yes | No | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 210 mm Zaxis, Table Mount, IP20+H1 Grease, iCS-ENET |

|

|

|

15 kg | 650 mm | 410 mm | Not required | IP20 | Yes | No | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 410 mm Zaxis, Table Mount, IP20+H1 Grease, iCS-ENET |

|

|

|

15 kg | 650 mm | 210 mm | Not required | IP20 | No | No | No | No | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 210 mm Zaxis, Inverted Mount, IP20, iCS-ENET |

|

|

|

15 kg | 650 mm | 410 mm | Not required | IP20 | No | No | No | No | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 410 mm Zaxis, Inverted Mount, IP20, iCS-ENET |

|

|

|

15 kg | 650 mm | 210 mm | Not required | IP20 | No | Yes | No | No | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 210 mm Zaxis, Inverted Mount, CR/ESD, iCS-ENET |

|

|

|

15 kg | 650 mm | 410 mm | Not required | IP20 | No | Yes | No | No | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 410 mm Zaxis, Inverted Mount, CR/ESD, iCS-ENET |

|

|

|

15 kg | 650 mm | 210 mm | Not required | IP65 | Yes | No | No | No | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 210 mm Zaxis, Inverted Mount, IP65+H1 Grease, iCS-ENET |

|

|

|

15 kg | 650 mm | 410 mm | Not required | IP65 | Yes | No | No | No | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 410 mm Zaxis, Inverted Mount, IP65+H1 Grease, iCS-ENET |

|

|

|

15 kg | 650 mm | 210 mm | Not required | IP20 | Yes | No | No | No | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 210 mm Zaxis, Inverted Mount, IP20+H1 Grease, iCS-ENET |

|

|

|

15 kg | 650 mm | 410 mm | Not required | IP20 | Yes | No | No | No | Yes | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-650H, 15 kg payload, 650 mm reach, 4 axis, 410 mm Zaxis, Inverted Mount, IP20+H1 Grease, iCS-ENET |

|

|

|

15 kg | 750 mm | 210 mm | Not required | IP20 | No | No | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-750H, 15 kg payload, 750 mm reach, 4 axis, 210 mm Zaxis, Table Mount, IP20, iCS-ENET |

|

|

|

15 kg | 750 mm | 410 mm | Not required | IP20 | No | No | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-750H, 15 kg payload, 750 mm reach, 4 axis, 410 mm Zaxis, Table Mount, IP20, iCS-ENET |

|

|

|

15 kg | 750 mm | 210 mm | Not required | IP20 | No | Yes | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-750H, 15 kg payload, 750 mm reach, 4 axis, 210 mm Zaxis, Table Mount, CR/ESD, iCS-ENET |

|

|

|

15 kg | 750 mm | 410 mm | Not required | IP20 | No | Yes | Yes | Yes | No | No | Yes | Yes | Yes | Yes | Yes | Yes | 4 | i4-750H, 15 kg payload, 750 mm reach, 4 axis, 410 mm Zaxis, Table Mount, CR/ESD, iCS-ENET |

|

Robotic Services

Control Units

Robot Control

- Total Integration (Control): Unified control automation + robotics

- Process Integration (Faster Time-to-market): Applications can be developed from design through commissioning, operation, and continuous improvement

- Supply Chain Integration (Flexibility): Users can easily reprogram (PLC and robots), modify, or scale production, providing flexibility to adapt to fluctuating demands

- Intel Atom processor, 20 MB user program capacity, 2GB SD card

- Runs Real-time Operating System and eV+3

- EtherCAT and Ethernet/IP communication

- Control Cycle: 0.5, 1, 2, 4 ms (Min 2 ms with ORT robots)

- SQL DB Functionality

- Can control NJ Robotics units (Deltas Codian & Yamaha, custom kinematics)

- Supports existing NJ accessories (Power supply, CJ-IO, cables)

- All non-robot features are consistent with existing NJ models

Stand-Alone Solution

- Stand Alone Pro-Version!

- No external controller is needed

- Communication capabilities same than legacy eCobra models.

- Mechanical adapter for eCobra models migration.

- On-board display for troubleshooting, maintenance and visual inspections

- Enable/disable power

- Jog the robot in different modes (joint, world, tool, frame)

- E-Stop button and 3-position enable switch

- Colorful and high resolution User Interface

- Teach locations

- Display robot position, digital I/O, and system status

- Display IP address of controller

- Product Includes

Vision & Inspection Guidance

- Built-in vision processor with 128GB SSD, optimized to process high resolution, high frame rate images, with ACE 4.X

- Unique simplified thermal design to maximize uptime

- GigE PoE and USB 3.0 ports for increased connectivity and fast data transmission

- Supports up to 8 cameras simultaneously

- Compatible with Omron UPS S8BA Series

- Compact design to minimize panel space, allowing 2 mounting orientations

Videos

-

Omron PackXpert: complete packaging solution

A complete single source integrated solution: robot, vision, motion, design & control. Manage your packaging line on your own with an intuitive, graphical interface. PackXpert Solution brings together our complete line of robotic automation products into a single, fully integrated packaging system. From design to implementation to product changeovers, with PackXpert, you’ll save time, lower costs and reduce the complexity of your packaging line.

01:21

Omron PackXpert: complete packaging solution

A complete single source integrated solution: robot, vision, motion, design & control. Manage your packaging line on your own with an intuitive, graphical interface. PackXpert Solution brings together our complete line of robotic automation products into a single, fully integrated packaging system. From design to implementation to product changeovers, with PackXpert, you’ll save time, lower costs and reduce the complexity of your packaging line.We’re Here to Help

Got a question? Our specialists are ready to assist you every step of the way.

Contact me i4H

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for i4H

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadRelated Products

-

For applications requiring high-speed processing for machine control, safety, reliability and maintainability.

-

New i4L robot for precision machining, assembly and material handling

-

Parallel robot ideal for use in the food and beverage, pharmaceutical, and healthcare industries

-

Four-axis parallel robot achieves high speed and high precision

_getting_started_guide_en.jpg)

_users_manual_en.jpg)