|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

0.2 kW |

0.4 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 0.2/0.4 kW (HD/ND), 1.6/2.0 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

0.2 kW |

0.4 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

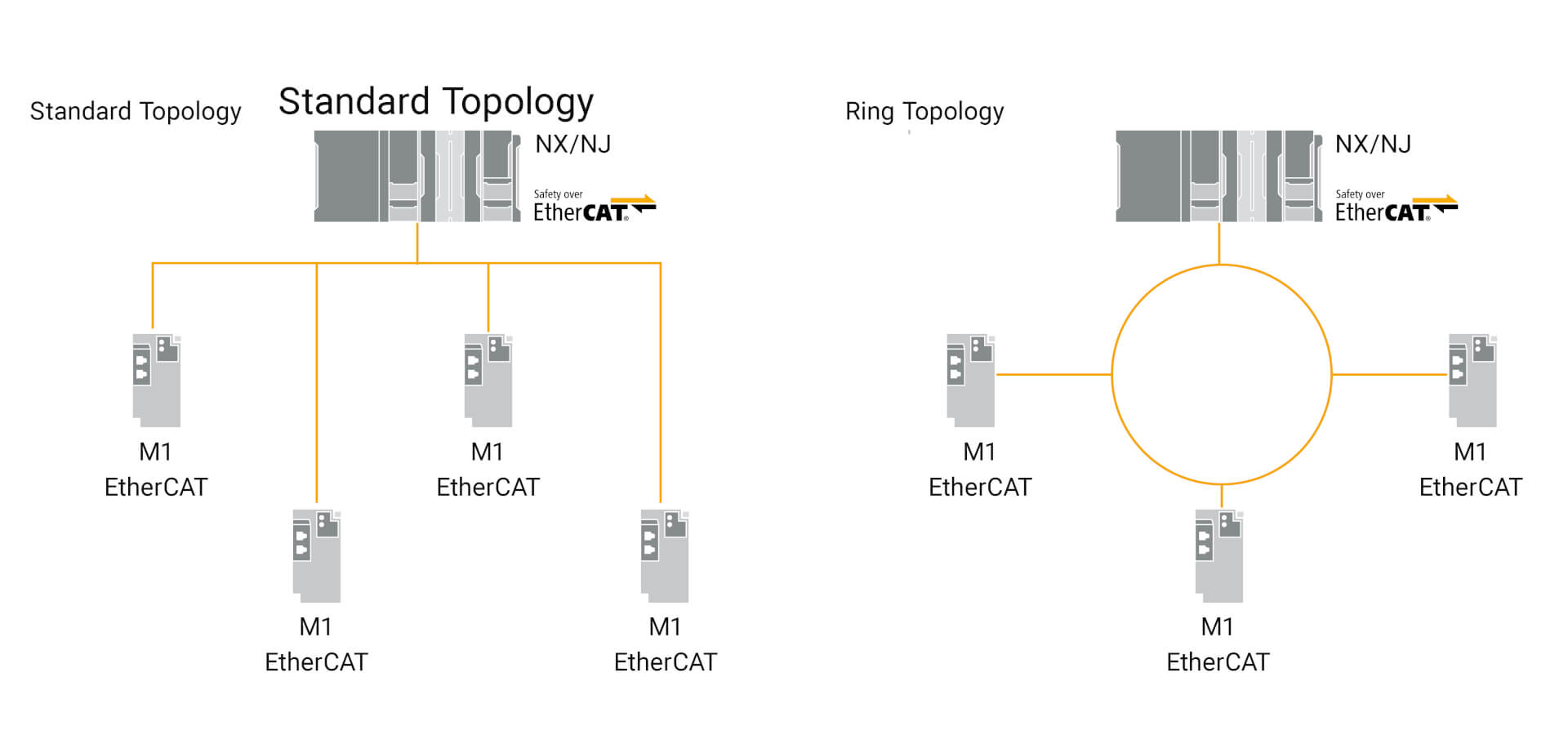

EtherCAT Slave, USB |

None |

No |

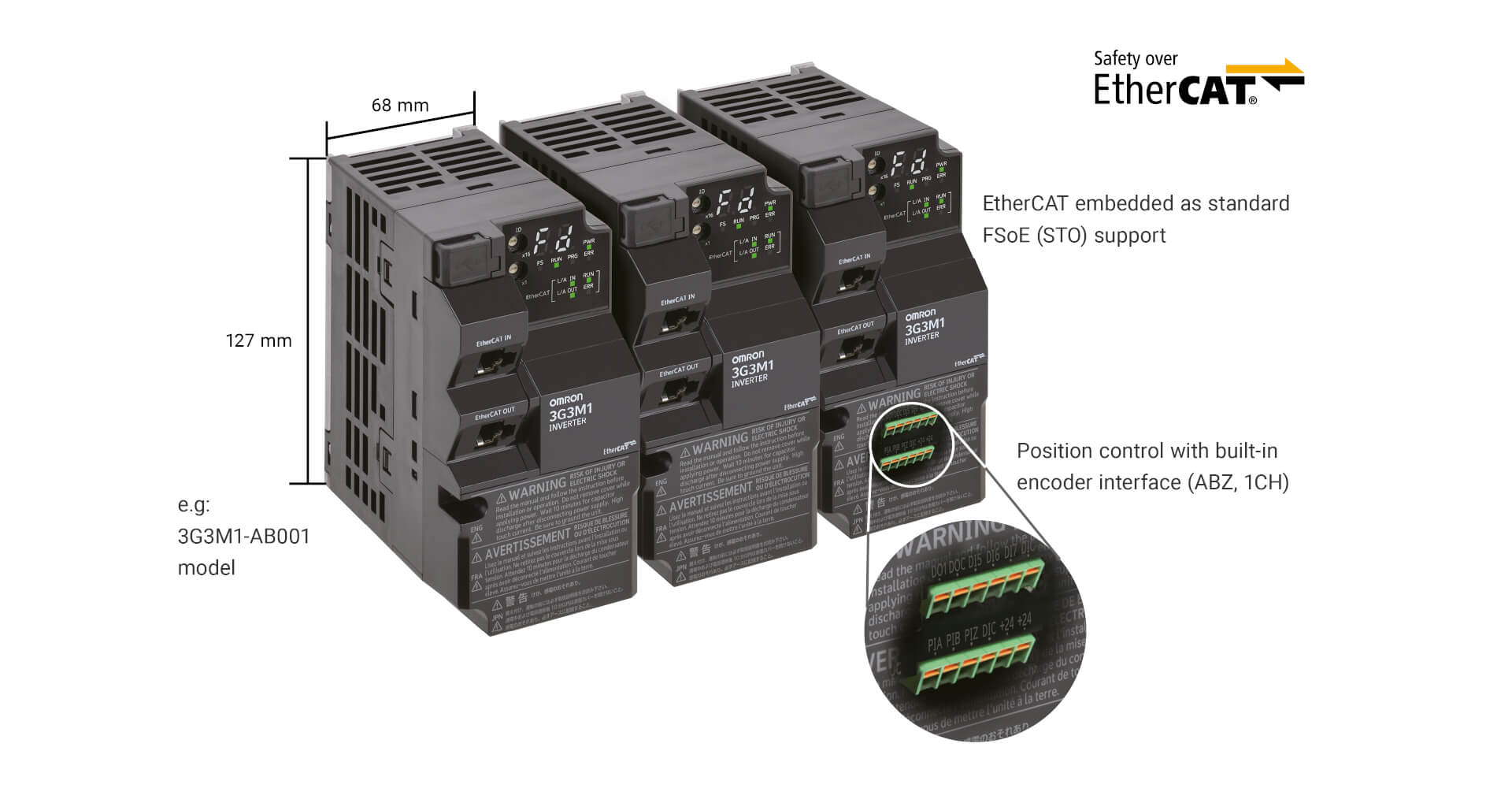

M1 AC Drive, 0.2/0.4 kW (HD/ND), 1.6/2.0 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

0.2 kW |

0.4 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

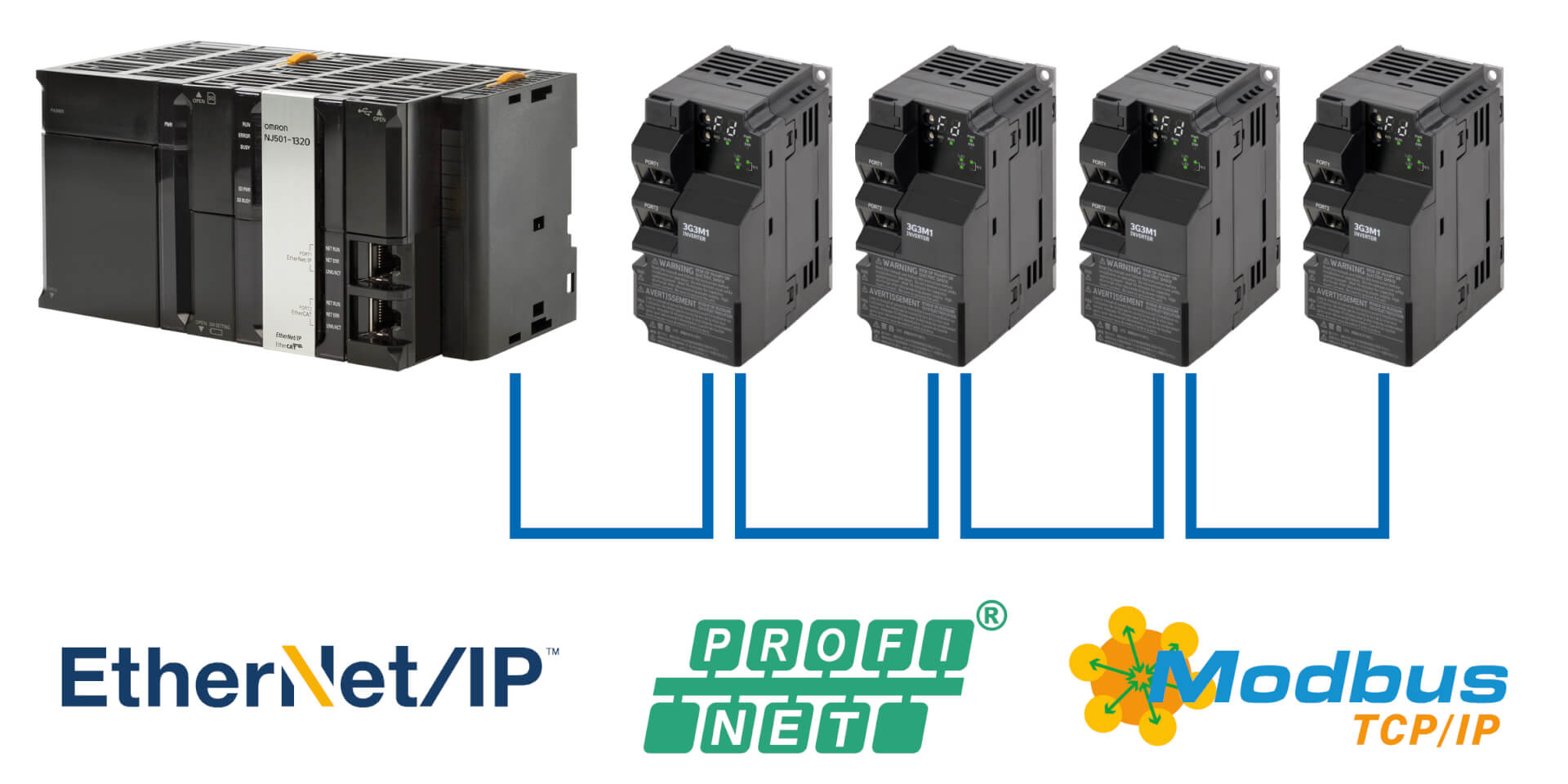

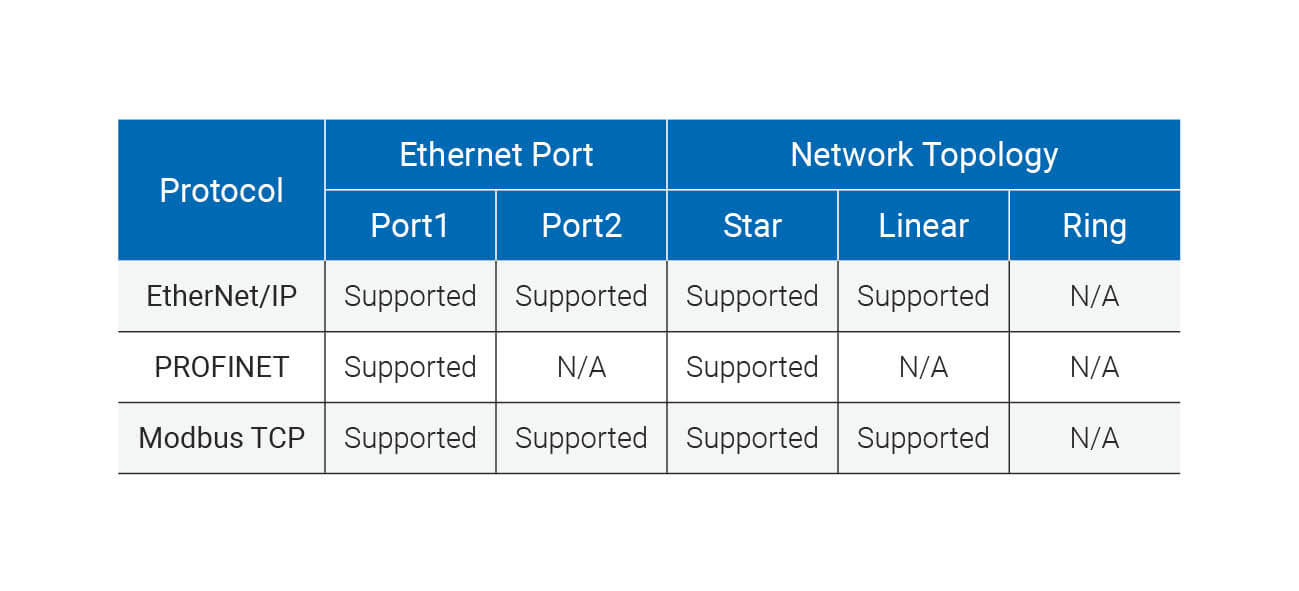

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 0.2/0.4 kW (HD/ND), 1.6/2.0 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

0.4 kW |

0.75 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 0.4/0.75 kW (HD/ND), 3.0/3.5 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

0.4 kW |

0.75 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 0.4/0.75 kW (HD/ND), 3.0/3.5 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

0.4 kW |

0.75 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 0.4/0.75 kW (HD/ND), 3.0/3.5 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

0.75 kW |

1.1 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 0.75/1.1 kW (HD/ND), 5.0/6.0 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

0.75 kW |

1.1 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 0.75/1.1 kW (HD/ND), 5.0/6.0 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

0.75 kW |

1.1 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 0.75/1.1 kW (HD/ND), 5.0/6.0 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 8.0/9.6 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 8.0/9.6 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 8.0/9.6 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

2.2 kW |

3.0 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 2.2/3.0 kW (HD/ND), 11/12 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

2.2 kW |

3.0 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 2.2/3.0 kW (HD/ND), 11/12 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

2.2 kW |

3.0 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 2.2/3.0 kW (HD/ND), 11/12 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

3.7 kW |

5.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 3.7/5.5 kW (HD/ND), 17.5/19.6 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

3.7 kW |

5.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 3.7/5.5 kW (HD/ND), 17.5/19.6 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

3.7 kW |

5.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 3.7/5.5 kW (HD/ND), 17.5/19.6 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

5.5 kW |

7.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 5.5/7.5 kW (HD/ND), 25/30 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

5.5 kW |

7.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 5.5/7.5 kW (HD/ND), 25/30 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

5.5 kW |

7.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 5.5/7.5 kW (HD/ND), 25/30 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

5.5 kW |

7.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 5.5/7.5 kW (HD/ND), 25/30 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

7.5 kW |

11 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 7.5/11 kW (HD/ND), 33/40 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

7.5 kW |

11 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 7.5/11 kW (HD/ND), 33/40 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

7.5 kW |

11 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 7.5/11 kW (HD/ND), 33/40 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

7.5 kW |

11 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 7.5/11 kW (HD/ND), 33/40 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

11 kW |

15 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 11/15 kW (HD/ND), 47/56 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

11 kW |

15 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 11/15 kW (HD/ND), 47/56 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

11 kW |

15 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 11/15 kW (HD/ND), 47/56 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

15 kW |

18.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 15/18.5 kW (HD/ND), 60/69 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

15 kW |

18.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 15/18.5 kW (HD/ND), 60/69 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

15 kW |

18.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 15/18.5 kW (HD/ND), 60/69 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

18.5 kW |

22 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 18.5/22 kW (HD/ND), 76/88 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

18.5 kW |

22 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 18.5/22 kW (HD/ND), 76/88 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V three phase |

18.5 kW |

22 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 18.5/22 kW (HD/ND), 76/88 A (HD/ND), 200 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

0.4 kW |

0.75 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 0.4/0.75 kW (HD/ND), 1.8/2.1 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

0.4 kW |

0.75 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 0.4/0.75 kW (HD/ND), 1.8/2.1 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

0.4 kW |

0.75 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 0.4/0.75 kW (HD/ND), 1.8/2.1 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

0.7 kW |

1.1 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 0.7/1.1 kW (HD/ND), 3.4/4.1 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

0.7 kW |

1.1 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 0.7/1.1 kW (HD/ND), 3.4/4.1 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

0.7 kW |

1.1 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 0.7/1.1 kW (HD/ND), 3.4/4.1 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 4.8/5.5 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 4.8/5.5 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 4.8/5.5 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 4.8/5.5 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

2.2 kW |

3.0 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 2.2/3.0 kW (HD/ND), 5.5/6.9 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

2.2 kW |

3.0 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 2.2/3.0 kW (HD/ND), 5.5/6.9 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

2.2 kW |

3.0 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 2.2/3.0 kW (HD/ND), 5.5/6.9 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

3.0 kW |

4.0 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 3.0/4.0 kW (HD/ND), 7.2/8.8 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

3.0 kW |

4.0 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 3.0/4.0 kW (HD/ND), 7.2/8.8 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

3.0 kW |

4.0 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 3.0/4.0 kW (HD/ND), 7.2/8.8 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

4.0 kW |

5.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 4.0/5.5 kW (HD/ND), 9.2/11.1 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

4.0 kW |

5.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 4.0/5.5 kW (HD/ND), 9.2/11.1 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

4.0 kW |

5.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 4.0/5.5 kW (HD/ND), 9.2/11.1 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

4.0 kW |

5.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 4.0/5.5 kW (HD/ND), 9.2/11.1 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

5.5 kW |

7.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 5.5/7.5 kW (HD/ND), 14.8/17.5 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

5.5 kW |

7.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 5.5/7.5 kW (HD/ND), 14.8/17.5 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

5.5 kW |

7.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 5.5/7.5 kW (HD/ND), 14.8/17.5 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

7.5 kW |

11 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 7.5/11 kW (HD/ND), 18/23 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

7.5 kW |

11 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 7.5/11 kW (HD/ND), 18/23 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

7.5 kW |

11 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 7.5/11 kW (HD/ND), 18/23 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

7.5 kW |

11 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 7.5/11 kW (HD/ND), 18/23 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

11 kW |

15 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 11/15 kW (HD/ND), 24/31 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

11 kW |

15 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 11/15 kW (HD/ND), 24/31 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

11 kW |

15 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 11/15 kW (HD/ND), 24/31 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

11 kW |

15 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 11/15 kW (HD/ND), 24/31 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

15 kW |

18.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 15/18.5 kW (HD/ND), 31/38 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

15 kW |

18.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 15/18.5 kW (HD/ND), 31/38 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

15 kW |

18.5 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 15/18.5 kW (HD/ND), 31/38 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

18.5 kW |

22 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 18.5/22 kW (HD/ND), 39/45 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

18.5 kW |

22 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 18.5/22 kW (HD/ND), 39/45 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

18.5 kW |

22 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 18.5/22 kW (HD/ND), 39/45 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

22 kW |

30 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 22/30 kW (HD/ND), 45/60 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

22 kW |

30 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 22/30 kW (HD/ND), 45/60 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

400 V three phase |

22 kW |

30 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 22/30 kW (HD/ND), 45/60 A (HD/ND), 400 VAC, 3~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

0.2 kW |

0.4 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 0.2/0.4 kW (HD/ND), 1.6/1.9 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

0.2 kW |

0.4 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 0.2/0.4 kW (HD/ND), 1.6/1.9 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

0.2 kW |

0.4 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 0.2/0.4 kW (HD/ND), 1.6/1.9 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

0.4 kW |

0.55 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 0.4/0.55 kW (HD/ND), 3.0/3.5 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

0.4 kW |

0.55 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 0.4/0.55 kW (HD/ND), 3.0/3.5 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

0.4 kW |

0.55 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 0.4/0.55 kW (HD/ND), 3.0/3.5 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

0.7 kW |

1.1 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 0.7/1.1 kW (HD/ND), 5.0/6.0 A (HD/ND), 200 VAC, 1~ input,OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

0.7 kW |

1.1 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 0.7/1.1 kW (HD/ND), 5.0/6.0 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

0.7 kW |

1.1 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 0.7/1.1 kW (HD/ND), 5.0/6.0 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 8.0/9.6 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 8.0/9.6 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 8.0/9.6 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

1.5 kW |

2.2 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 1.5/2.2 kW (HD/ND), 8.0/9.6 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

2.2 kW |

2.7 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 2.2/2.7 kW (HD/ND), 11/12 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

2.2 kW |

2.7 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 2.2/2.7 kW (HD/ND), 11/12 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590 Hz.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

2.2 kW |

2.7 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 2.2/2.7 kW (HD/ND), 11/12 A (HD/ND), 200 VAC, 1~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

3.7 kW |

3.7 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

MODBUS Slave, Serial RS-485, USB |

None |

No |

M1 AC Drive, 3.7 kW (HD), 17.5 A (HD), 200 VAC, 1~ input, OLV/CLV control, STO (wired), max. output freq. 590 Hz

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

3.7 kW |

3.7 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 3.7kW (HD), 17.5 A (HD), 200 VAC, 1~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590Hz EtherCAT version.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

3.7 kW |

3.7 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherCAT Slave, USB |

None |

No |

M1 AC Drive, 3.7kW (HD), 17.5 A (HD), 200 VAC, 1~ input, OLV/CLV control, EtherCAT, STO (FSoE + wired), max. output freq. 590Hz EtherCAT version.

|

|

|

|

Closed loop V/f, Closed loop vector, Open loop V/f, Open loop vector, V/f control, Vector control |

230 V single phase |

3.7 kW |

3.7 kW |

No |

IP20 |

Induction or asynchronous motor, Permanent magnet motor |

EtherNet/IP, MODBUS/TCP, PROFINET Slave, USB |

None |

No |

M1 AC Drive, 3.7kW (HD), 17.5 A (HD), 200 VAC, 1~ input, OLV/CLV control, Ethernet Multi-Protocol (EtherNet/IP, PROFINET and Modbus TCP), max. output freq. 590 Hz

|

|