K7DD-PQM

Power quality monitoring

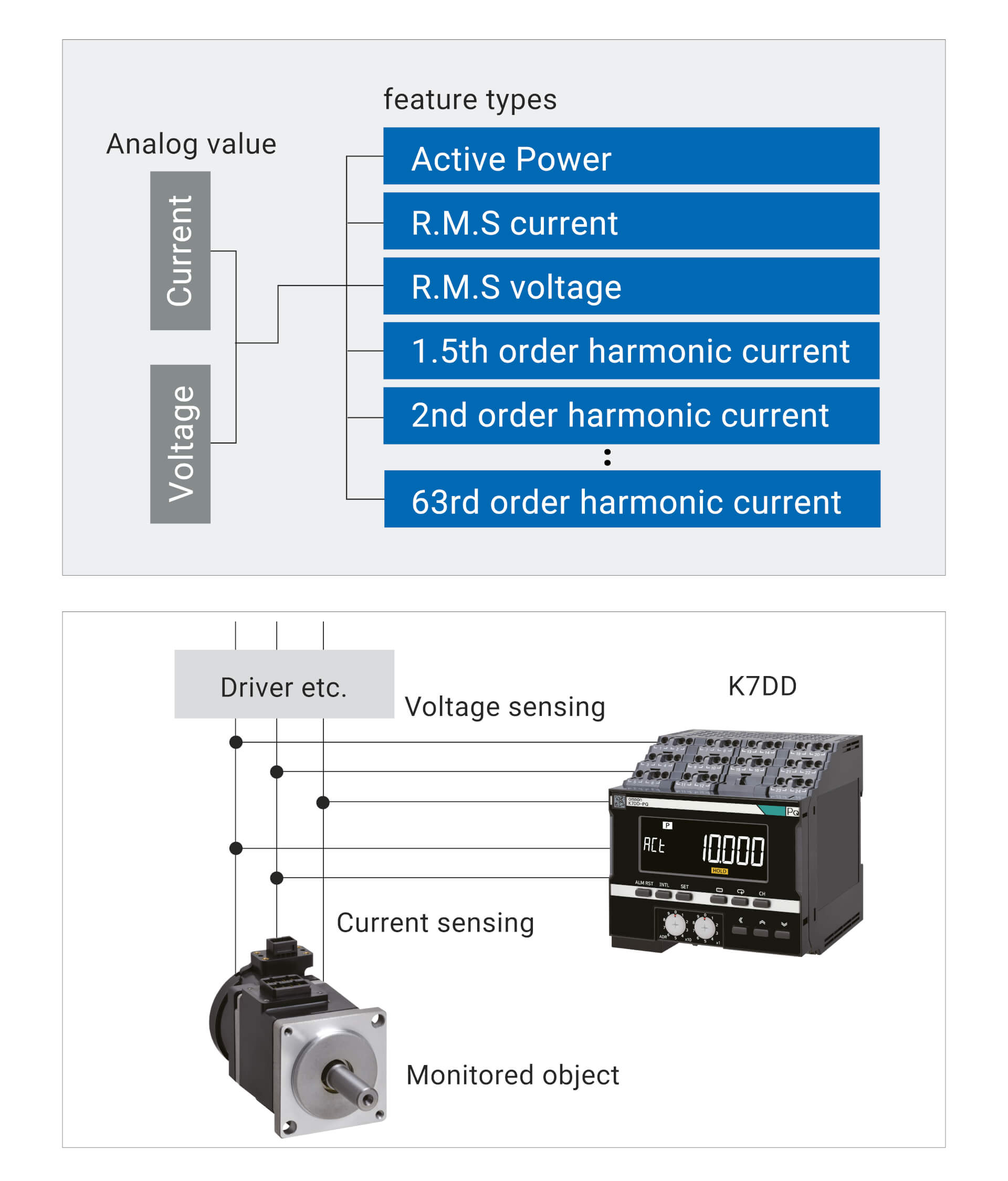

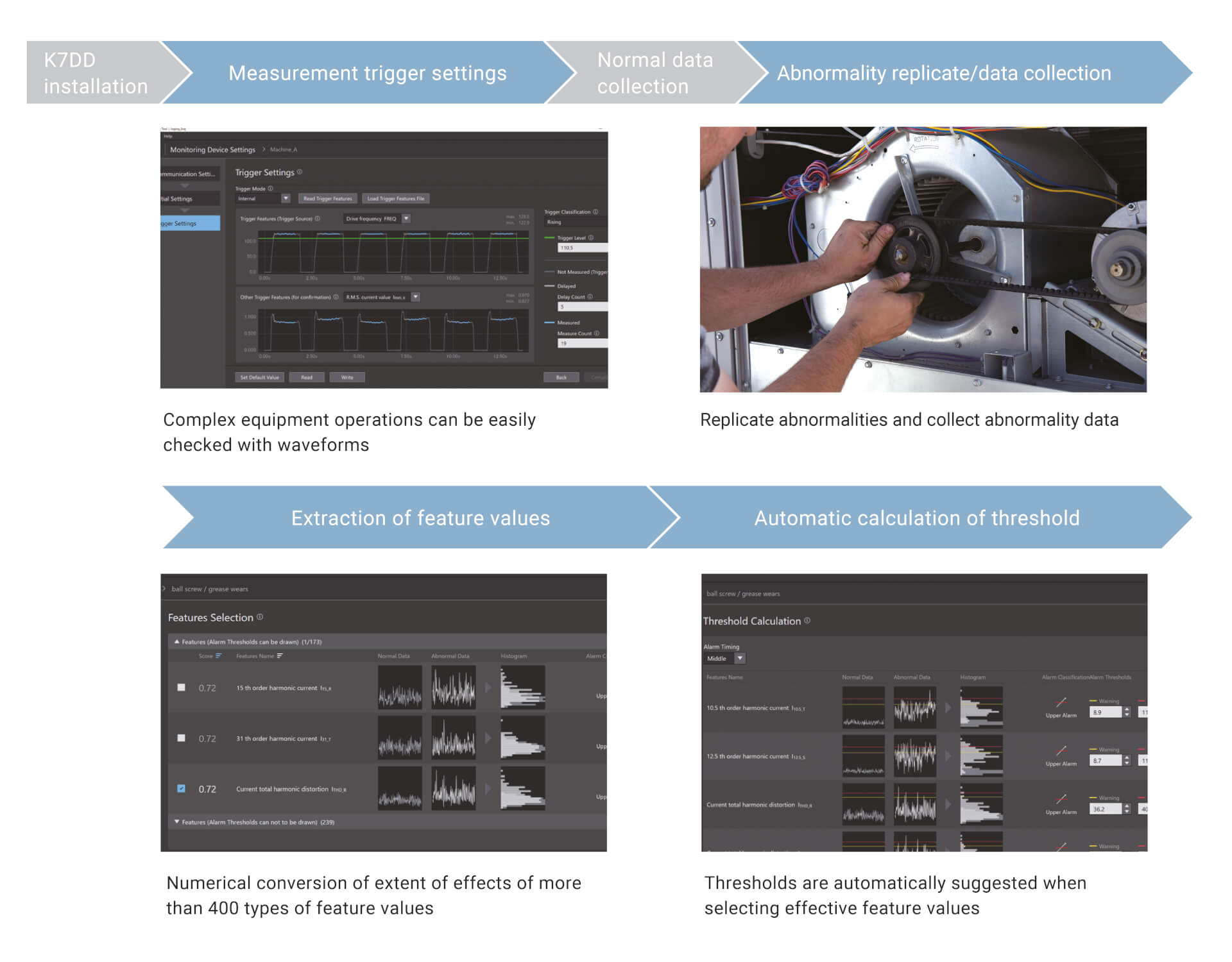

K7DD-PQM detects failures of various motor parts using the feature values of captured power quality

The K7DD-PQM advanced motor condition monitoring device makes it possible to identify failure modes and defect parts of motor equipment while rapidly translating power quality such as motor current and voltage into data. This enables scheduled maintenance activities with real-time condition monitoring of motors that frequently change speed, which were difficult to identify abnormalities so far. And simplified condition monitoring device parameter configuration process is contributed to understand K7DD-PQM installation efficiency quickly.

- Samples up to 6 channels (current and voltage) simultaneously at 2.5μs

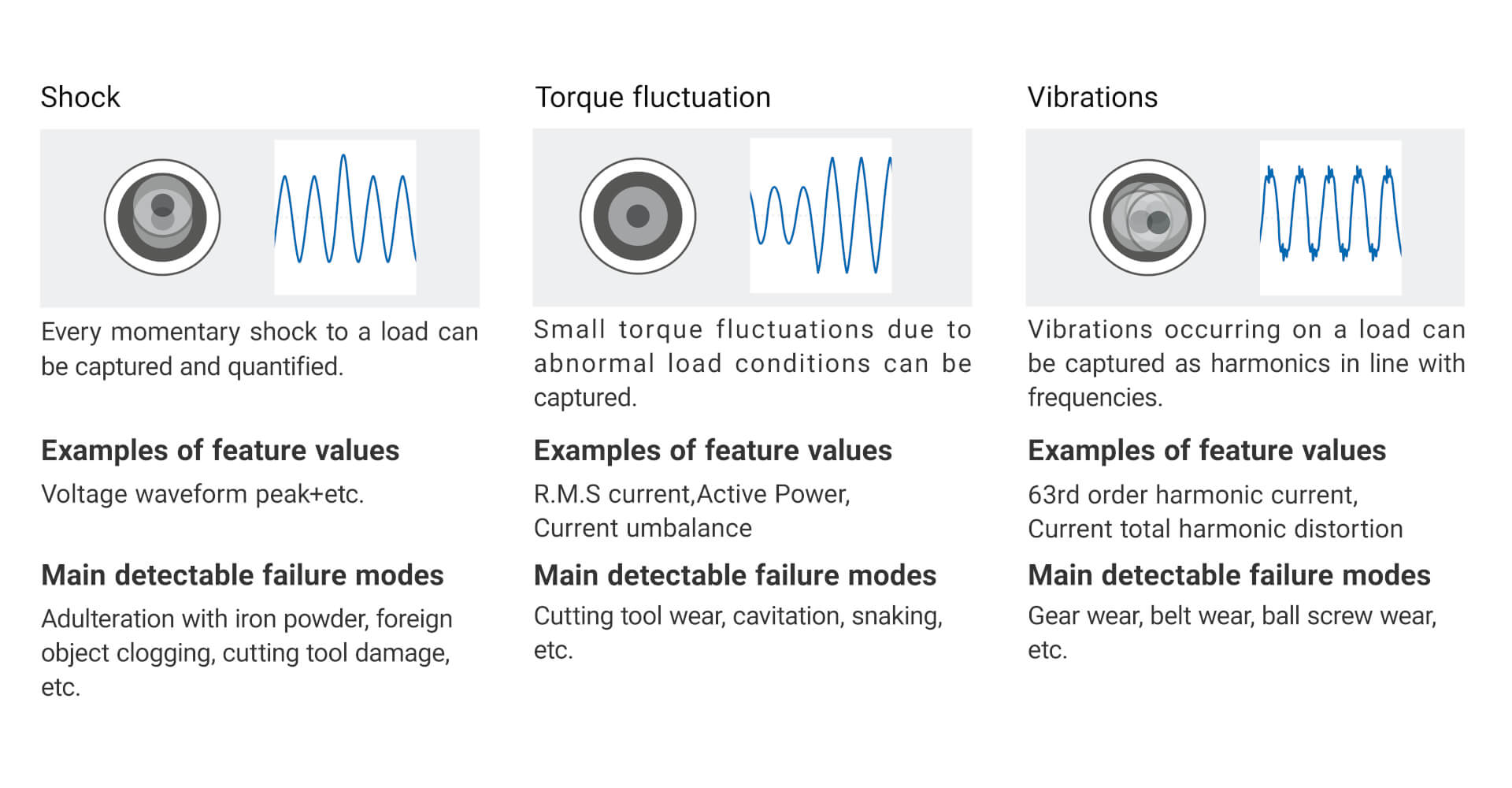

- Abnormalities on the motor & rotating shaft & load side can be judged individually

- SW tool minimize analysis skills requirement

Specifications & ordering info

| Product | Supply voltage AC | Supply voltage DC | Description | |

|---|---|---|---|---|

|

|

100-240 V | Advanced Motor Condition Monitoring Device, 100 to 240 VAC, transistor control output, Push-in Plus, LCD display, RS-485/Modbus/RTU |

|

|

|

|

24.85-26.4 V | Advanced Motor Condition Monitoring Device, 24 VDC, transistor control output, Push-in Plus, LCD display, RS-485/Modbus/RTU |

|

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact me K7DD-PQM

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for K7DD-PQM

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFeatures

Measure the power quality of motors

The K7DD samples up to 6 channels simultaneously at 2.5μs. By operating 3-phase power line current/voltage every 50 ms, it detects over 140 types of feature values.

Monitors servo and induction motors

A variety of factors may cause motor equipment failure. K7DD makes it possible to monitor these failure modes individually and suggest subsequent actions to be taken by maintenance staff depending on the condition.

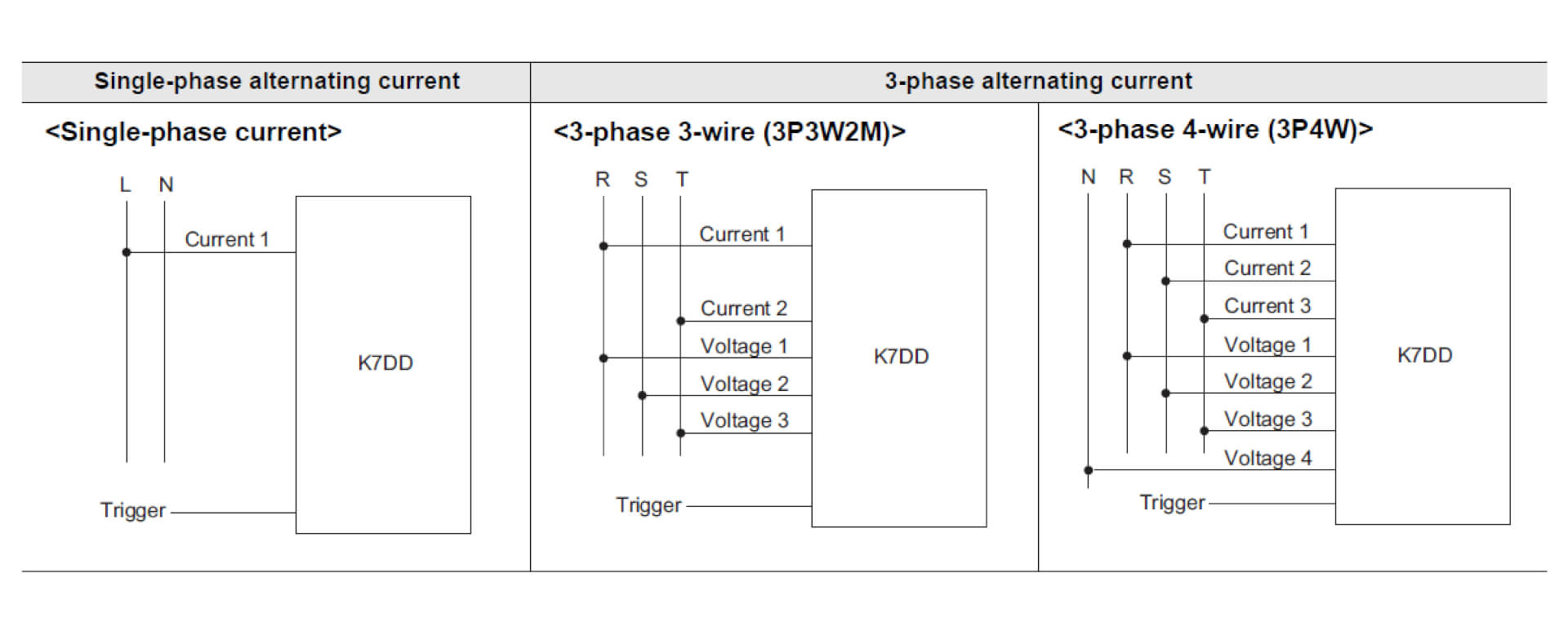

Three wiring methods possible

K7DD can measure both the voltage and current or only the current of power lines that drive motors, valves, and other measurement targets.

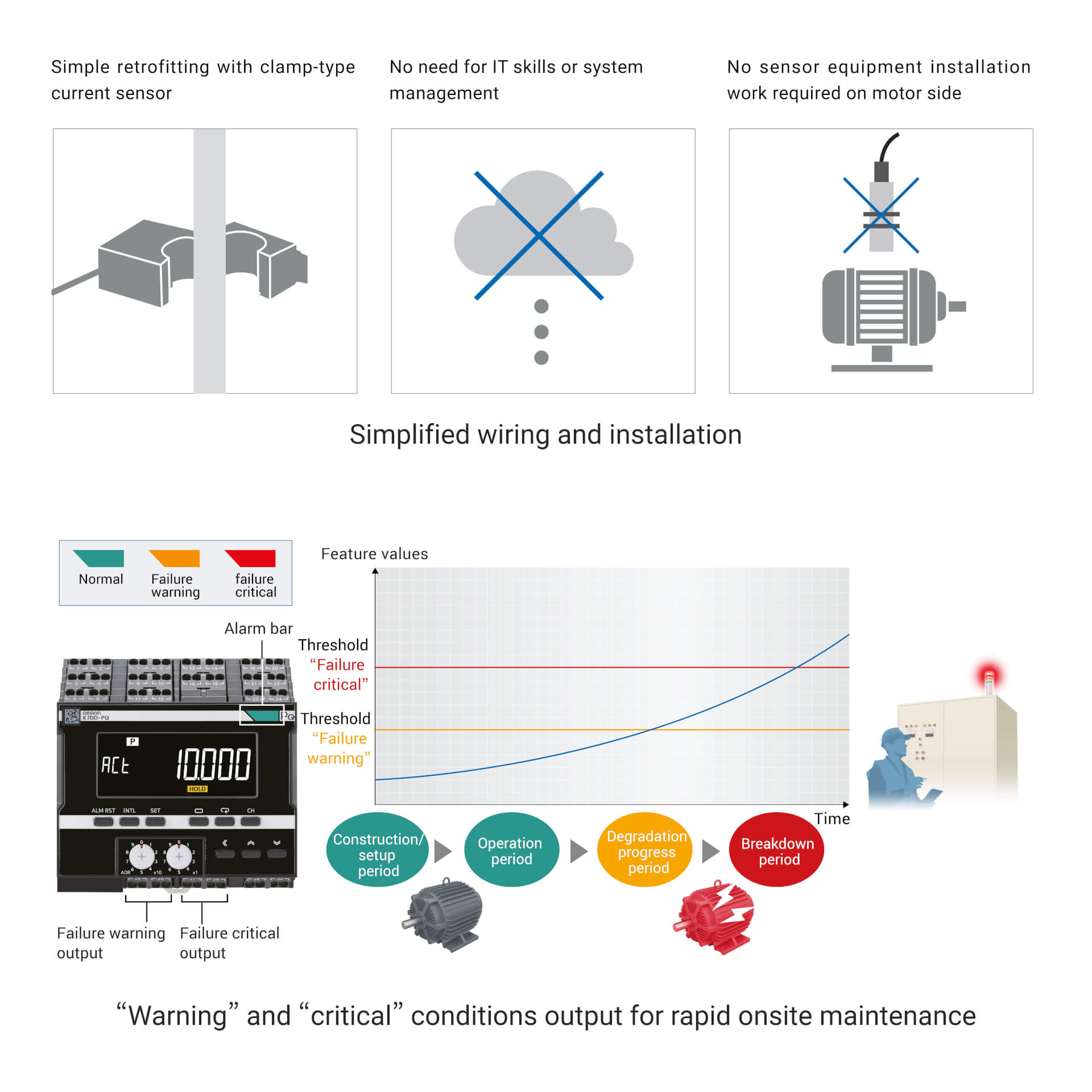

Simple retrofitting

Using clouds, data servers, or other IT devices not only requires system-building skill and coordination with IT administrators, but also necessitates specialist installation work. The K7DD do not require special skills, and it can be retrofitted with minimal installation workload. After installation, you can check abnormal conditions from the K7DD display screen directly.

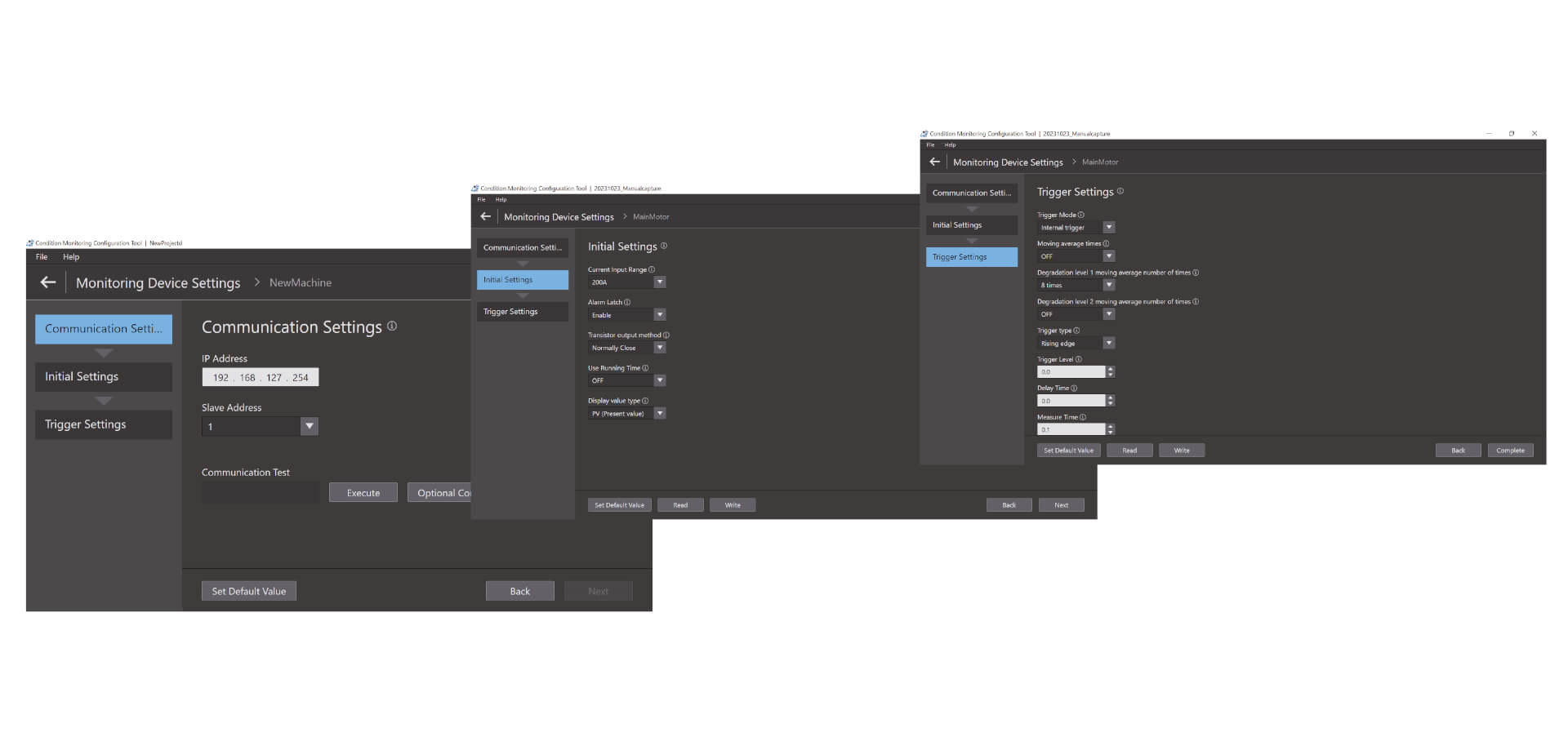

Condition monitoring devices can be configured with a single tool

Easy three-step configuration The Condition Monitoring Configuration Tool allows for batch configuration of a wide range of condition monitoring devices, such as those for monitoring motors, temperatures, insulation, and heaters. It can be used without any special skills, reducing training effort

Easy three-step configuration

The Condition Monitoring Configuration Tool allows for batch configuration of a wide range of condition monitoring devices, such as those for monitoring motors, temperatures, insulation, and heaters. It can be used without any special skills, reducing training effort. Setup can be completed in just three steps: communications setup, initial setup, and trigger setup.*1 With its high operability, the tool boosts on-site productivity as well.

Videos

-

OMRON K7DD - The Power Quality Monitoring Device

Introducing the OMRON K7DD Power Quality Monitoring device—a game-changer in advanced motor condition monitoring! Swiftly identify failure modes and defective motor parts by translating motor current and voltage into actionable data. Now, conduct scheduled maintenance with real-time monitoring for motors that undergo frequent speed changes, addressing abnormalities that were once hard to detect. Experience enhanced efficiency with the simplified parameter configuration process, ensuring a quick grasp of K7DD installation. Elevate your motor equipment's performance with OMRON's cutting-edge technology!

02:05