Latest news

OMRON awarded platinum rating from EcoVadis for sustainability

22 December, 2022 OMRON's EcoVadis Platinum rating, the highest distinction, puts the company within the top 1% of all the businesses assessed for sustainability performance.

OMRON adds EtherCAT models to i4L SCARA robot series

19 December, 2022 OMRON’s has announced the availability of new EtherCAT models in the i4L SCARA robot series. The compact i4L robots now offer even stronger performance at the lowest total cost of ownership. Robotic Integrated Controller allows synchronized multi-robot applications with EtherCAT models.

Goal Carbon Zero: OMRON Commits to Doubling Energy Productivity by 2040

16 November, 2022 OMRON has become a member of The Climate Group's "EP100" initiatives. OMRON is the first Japanese company in the manufacturing industry and the fourth Japanese company in general to join the EP100 initiative, which brings together over 120 energy smart businesses committed to measuring and reporting on energy efficiency improvements.

OMRON’s Mobile Robots Win the METI Minister’s Award at the 10th Robot Awards Program

10 November, 2022 OMRON LD Series and HD Series mobile robots have won the prominent Ministry of Economy, Trade and Industry (METI) Minister’s Award at the 10th Robot Awards program, which is chiefly co-organized by METI and the Japan Machinery Federation.

OMRON Invests in Kirin Techno-System, a Comprehensive Manufacturer of Inspection Machines

19 October, 2022 To supply safe and secure beverages and to further accelerate global environmental conservation.

OMRON Releases New FH-SMD Series 3D Vision Sensor for Robot Arms

12 October, 2022 Vision sensor enables human-like detection and flexibility for automating part picking

OMRON Launches Safety Virtual Experience: A guide to safe automation in flexible manufacturing

05 October, 2022 The new Safety Virtual Experience from OMRON provides a 360-degree view of safety solutions for factory floors in automotive and intralogistics applications.

OMRON launches ROI calculator for mobile and collaborative robots

01 September, 2022 A new ROI calculator from OMRON has been launched to support the process of evaluating an investment in collaborative and mobile robots, including easy and affordable leasing opportunities that are ideal for small and medium enterprises (SMEs).

OMRON introduces OMRON TM16 collaborative robot with a payload of 16kg

10 August, 2022 The OMRON TM16 cobot adds more power and versatility to OMRON’s strong collaborative robot lineup.

Increased precision: Robert Bosch GmbH chooses new OMRON inline 3D CT X-ray inspection system VT-X750

04 August, 2022 Printed circuit boards (PCBs) are central component of numerous electrical devices, and the automotive industry is also increasingly dependent on PCBs that do not have any weak points.

OMRON Acquires Science Based Targets Initiative Certification

19 July, 2022 Based on the greenhouse gas (GHG) emissions reduction targets set in its long-term vision, Shaping the Future 2030 (SF2030), OMRON paves the way for achieving the goal of limiting global warming to 1.5 degrees Celsius advocated by the Paris Agreement.

OMRON Adds Selectable Autonomy and FLOW iQ to FLOW Core Fleet Management Software

11 July, 2022 Driving flexible manufacturing with mobile robots in complex material transport applications

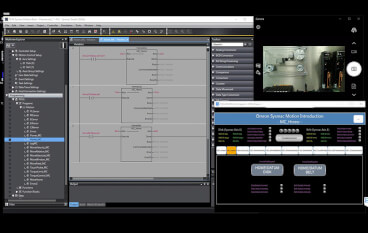

Sysmac Studio 3D Simulation boosts productivity

22 October, 2020 Logic, motion, robotics, HMI, vision, sensing, safety and 3D simulation are all integrated within a single platform.

-

Game-changer in disinfection - HERO21 autonomous UV-C mobile robot solution for hospitals

An innovative contribution to health and safety - a robot that makes disinfection easy. The importance of disinfection in hospitals has increased considerably – and not just because of the coronavirus pandemic. Conventional disinfection methods, such as manual disinfection, only solve the problem rudimentarily. Often, they even produce more resistant germs. UV-C robots can help out: reliable, with state-of-the-art technology and high efficiency – and an optimal price-performance ratio. Whether in operating rooms, intensive care units or other highly sensitive areas of hospitals: The HERO21 provides the highest level of disinfection and thus offers optimum protection. After the initial disinfection of contaminated rooms, even the cleaning staff who normally work at the frontline are exposed to a much lower risk of infection. Read more about the HERO21: Read more about OMRON autonomous mobile robots:

04:07

OMRON and ICA Traffic present the first UV disinfection solution "Made in Germany"

08 October, 2020 HERO21 is based on the LD autonomous mobile robot from OMRON for maximum efficiency. Mobile robot moves autonomously and quickly through the rooms to be disinfected.

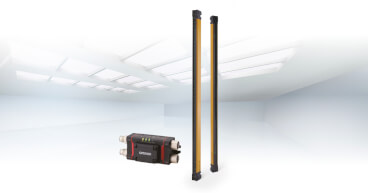

F3SG-SR/PG series offers an ALL in ONE Line-Up

18 September, 2020 The F3SG-SR/PG series offers a complete range of safety light curtains and multi-beam that covers all applications from machine openings to perimeter and access guarding.

Omron ‘virtual hands on’ distance learning service

01 September, 2020 Omron are pleased to offer a new training experience. Our training courses are now available as remote courses, delivered to you at your home, office or factory.

New FH Vision System with industry’s first AI defect detection

01 September, 2020 The image processing system identifies subtle defects with human-like sensitivity to achieve higher defect detection rates.

OMRON Announces the World's First “Robotic Integrated Controller” to Control Fully Automated Robotic Production Systems

29 July, 2020 New solution extends automation technology by automating manual work, and innovating manufacturing in virtual and remote environments.

Omron TM12 cobot automates booklet feeding for Kraus Maschinenbau

28 July, 2020 Cobots streamline processes in medtech and packaging industry

-

Introducing OMRON HD-1500 Mobile Robot

Introducing OMRON’s strongest mobile robot: the HD-1500. The HD-1500 is an advanced autonomous mobile robot specifically designed to transport heavy payloads up to 1500 kilograms. The HD-1500 also represents innovations in mobile robotics. Its new architecture features lasers that provide 360-degree safety coverage, as well as an onboard programmable logic controller, or PLC, to easily interface with custom attachments. Heavier payloads, built-in controller, improved sensors, route planning and object avoidance, the OMRON HD-1500 autonomous mobile robot offers the most advanced performance and safety. Learn more:

03:00

New HD-1500 mobile robot with 1500kg payload capacity

22 July, 2020 Industry-leading HD-1500 expands the possibilities for autonomous material transport

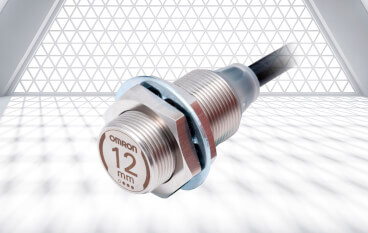

Reliable detection for iron and aluminum with new E2EW Series metal face proximity sensors

01 July, 2020 We have announced the release of the E2EW Series metal face proximity sensors that are designed to minimize downtime thanks to their durable construction and exceptionally long sensing range.

OMRON Fleet Simulator offers the industry’s first mobile robot simulator for factory and manufacturing applications

27 May, 2020 Omron offers a new solution for optimizing an entire fleet before deploying.

-

New MicroHAWK V/F400 and V/F300 Series Smart Cameras

Omron Industrial Automation recently launched the new V/F400 and V/F300 Series Smart Cameras, the latest additions to its popular MicroHAWK line. A new solution available for manufacturers who are concerned that their product inspections are becoming too complex. The powerful yet compact MicroHAWK V/F400 and V/F300 Series Smart Cameras simplify applications by combining code reading and vision inspection into a single, highly compact device. By bundling multiple capabilities in one, the V/F400 and V/F300 Series lower hardware costs and minimize the work required for commissioning and maintenance.

01:09

New MicroHAWK V- and F-Series Smart Cameras simplify code reading and inspection with ultra-small footprints

20 April, 2020 The V/F400 and V/F300 Series Smart Cameras are the latest additions to OMRON’s popular MicroHAWK line that offers both code reading and vision inspection capabilities.

Omron’s NA Series offer new models and functionalities

20 April, 2020 The new NA Series are the next generation of Machine Interface, a range of options and models that covers every need.

OMRON UK COVID-19 Operational Statement

02 November, 2020 We are in unprecedented times, facing challenges we could not have foreseen. The safety and well-being of all our employees, their relations, our customers and visitors throughout the COVID-19 pandemic is and will remain our highest priority.

Disinfection solution with UV-equipped mobile robots

17 June, 2020 OMRON joins forces with partners to provide a new disinfection solution with UV-equipped mobile robots.

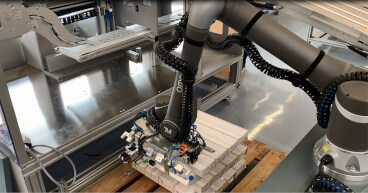

Robots speed up the production of Covid-19 tests

08 June, 2020 Medtech company Senova relies on OMRON’s smart robotics in the production of rapid antibody tests that show immunity within a few minutes

Technical Support

01 May, 2020 Many of our local offices are currently closed and staff are working remotely. Our support staff however continues working as normal from their homes. We would like to stress that we are very much still open for business and whilst response times in certain areas may be a little slower than normal we will endeavor to maintain the same high level of service you have come to expect from Omron, albeit provided in a different way.

Delivery information

01 May, 2020 We are committed to maintaining business continuity towards our customers, suppliers and partners to manage these challenging times and get through this global crisis.

A message from our CEO Seigo Kinugawa to customers and partners

28 April, 2020 These are very challenging times as the world responds to the coronavirus outbreak. Like you, I am watching the rising numbers of infections with concern and have great admiration for all those who are in the front lines combating the effects of the virus, our hearts and thoughts go out to the people who have been affected by the unprecedented events we see unfolding around us.

TheOpenVentilator: mass production of ventilators to start after successful clinical trials in Spain

22 April, 2020 OMRON has contributed, with the non-profit association TheOpenVentilator, to the development of an emergency ventilator for compassionate-use, built with quality equipment and industrial reliability, to help patients requiring mechanical ventilation due to COVID-19.

Statement from OMRON on the coronavirus (COVID-19) outbreak

07 April, 2020 We are closely following the development of the coronavirus outbreak in the EMEA region. While we adhere to the guidance from relevant authorities and the WHO, the safety and well-being of all our employees and relations is our highest priority.

OMRON receives Top 100 Global Innovators award for fourth consecutive year

05 March, 2020 OMRON has been selected as one of the Derwent Top 100 Global Innovators 2020 by Clarivate Analytics for the fourth consecutive year since 2016.

FHV7-Series Smart Camera wins iF DESIGN AWARD 2020

04 March, 2020 OMRON has received the iF DESIGN AWARD for the FHV7-series Smart Camera in this year's competition.

Green supplier certification highlights commitment to sustainability

02 December, 2019 Green procurement aims to minimize negative environmental impact across the supply chain.

Committed to customer satisfaction

02 December, 2019 Customer survey shows improved satisfaction rates, development projects underwayeNews explained

Subscribe to Omron’s eNews today and you will receive the latest copy of our email newsletter, eNews.

Learn more