Human personnel is the most common source of contamination in cleanroom operations. OMRON and its partners not only work on solutions to automate this area, but also extend to ballroom approaches in response to requests for increased flexibility.

Increase sterility in the cleanroom, cope with Annex 1

How can the risk of contamination in a cleanroom be reduced?

How can errors, most of which come from humans, be prevented?

How can line clearance time be minimized?

Are there opportunities to automate environmental monitoring?

Are there solutions for automated machine supply, waste removal, and settle plate handling?

OMRON is constantly working on these and other questions, developing solutions in collaboration with partners and end users.

Solutions for flexible shopfloor and cleanroom automation

OMRON solutions are primarily based on collaborative robotics for two simple reasons: they can operate in very limited spaces and, if necessary, alongside people. Additionally, OMRON collaborative robots are designed to emit no more particles than allowed for all pharmaceutical cleanroom classification.

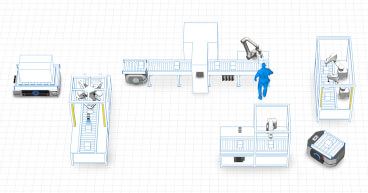

Different use case scenarios of automation within a pharmaceutical production plant

Automating cleanroom applications provides repeatable, error-free, fully traceable, and contamination-free solutions for your operations. The latest technology is used to address sometimes complex challenges. OMRON and its partners offer consultation to identify automatable processes, design tailored solutions, and provide support for your validation process. Reliability and sustainability are guaranteed, as OMRON solutions are built for industrial use.

Enabling Technologies

Life Science

In the Life Science industry, we create it special, we automate it safe, secure, and simple. OMRON is your trusted partner for zero touch, zero defect autonomous and collaborative pharma factory.

Customer References

Explore how our industrial automation solutions have helped our customers solve challenges and improve productivity, safety and efficiency.

Safety Services

Make your machines safe and compliant. Regional support on global scale.

Related Links and Products

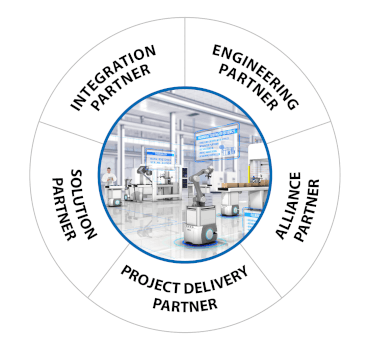

Innovation Partners

The OMRON Innovation Network offers a platform for organizations that share our commitment to delivering cutting-edge solutions, empowering businesses to thrive in the ever-evolving digital landscape.

Collaborative robots assembly, packing, inspection and logistics

OMRON TM cobots are geared toward manufacturers seeking to boost production and reduce employee fatigue by automating repetitive tasks such as machine tending, loading and unloading, assembly, screw driving, gluing, testing or soldering. Whether you’re working in automotive, semiconductors, secondary packaging for food, plastics, or machine tools, the Omron TM Collaborative Robot is designed to adapt to almost any industry.

For applications requiring high-speed processing for machine control, safety, reliability and maintainability.

Our Robotics Integrated Controller perfectly synchronizes automation technology so that customers can improve the speed and accuracy of their production, simulate entire production line, simplify maintenance, and reduce time-to-market.

Downloads

Related Solutions

Consultation Desk Services

Receive cross-border support and expertise in your own language. Consultation Desk Service enables a quick and cost-efficient cross-border service without compromising with quality

Omron Mobile Manipulator Solution

Combining a collaborative robot and a mobile robot, the Mobile Manipulator hybrid concept, or MoMa, is a new breed of robot with all the benefits and none of the limitations of these technologies.

Fleet Simulator - Optimize your fleet before you deploy it

OMRON Fleet Simulator offers the industry’s first mobile robot simulator for factory and manufacturing applications.