Today's Challenge: The consistency to trace extensively

Our Solution: 100% Code reading guarantee

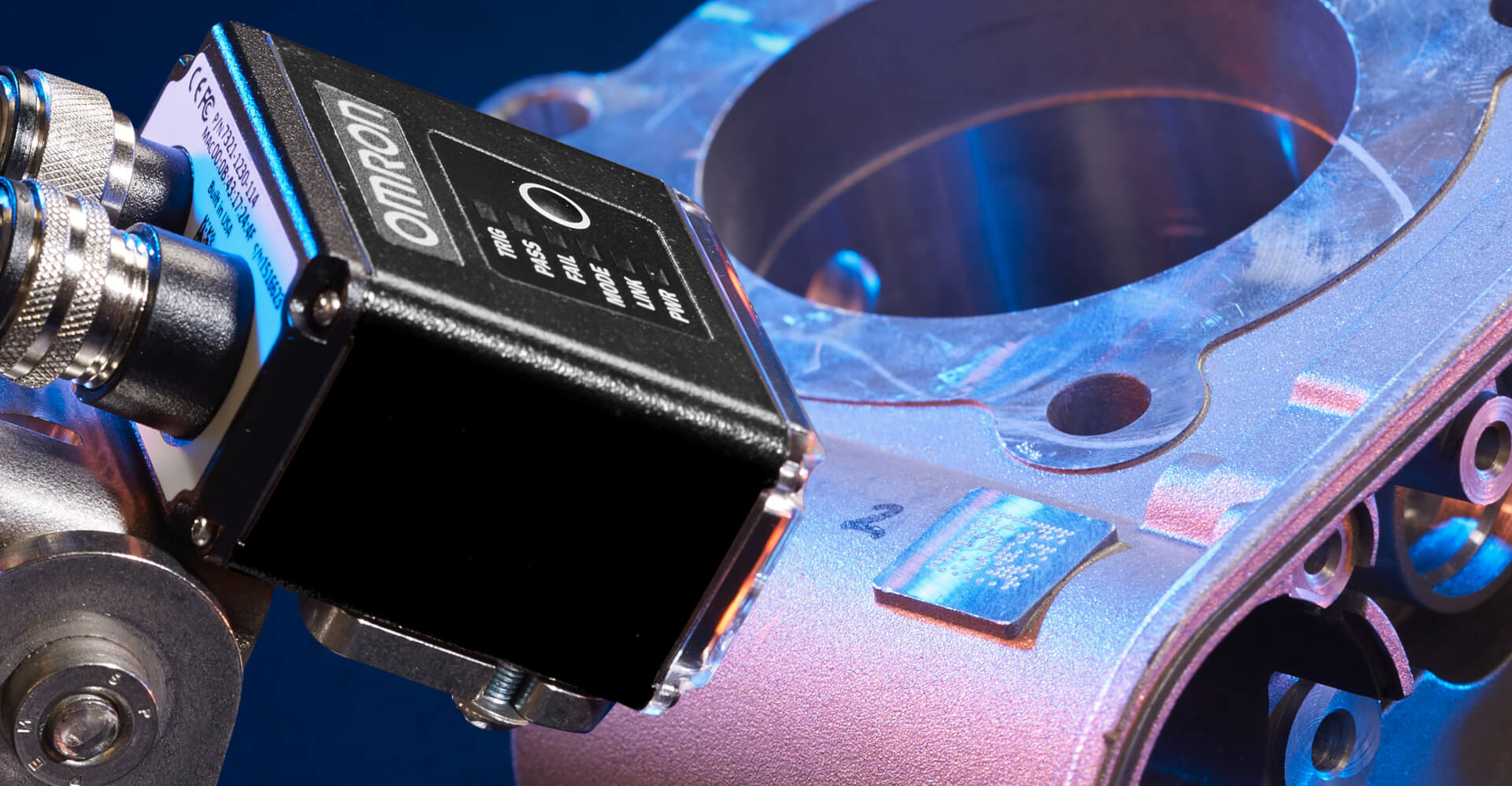

With our X-Mode decoding algorithm and autofocus capabilities, even the most challenging direct part marks will read reliably with almost no set-up required. Built-in checks monitor code quality while reading and function as an early warning system for code quality problems. This guarantees that no unreadable codes leave the factory. Our high-resolution code readers have the large field of view needed for reading multiple codes in packaging aggregation applications.

Many factory systems rely on radio frequency identification -or RFID- for identifying products. RFID based systems use RFID tags attached to a product or product carrier as a form of unique identification. RFID tags can not only provide unique identification but can also be used to store data. This allows applications, where traceability data is stored on the tag during production, to be uploaded to a traceability database at the end of the line.

Benefits of our code reading solutions:

-

Avoid machine stops and manual work from missed reads

-

Read even the toughest codes with minimal set-up

-

Detect readability issues before missed reads occur

-

Read multiple codes simultaneously

-

Easy communication

See Our Solution in Action

-

Barcode reading at its best: MicroHAWK V/F400 and V/F300 Series Smart Cameras

OMRON recently launched the V/F400 and V/F300 Series Smart Cameras, the latest additions to its popular MicroHAWK line. The solution is ideal for manufacturers who are concerned that their product inspections are becoming too complex. The powerful yet compact MicroHAWK V/F400 and V/F300 Series Smart Cameras simplify applications by combining code reading and vision inspection into a single, highly compact device. By bundling multiple capabilities in one, the V/F400 and V/F300 Series lower hardware costs and minimize the work required for commissioning and maintenance. Read more:

01:09

Barcode reading at its best: MicroHAWK V/F400 and V/F300 Series Smart Cameras

OMRON recently launched the V/F400 and V/F300 Series Smart Cameras, the latest additions to its popular MicroHAWK line. The solution is ideal for manufacturers who are concerned that their product inspections are becoming too complex. The powerful yet compact MicroHAWK V/F400 and V/F300 Series Smart Cameras simplify applications by combining code reading and vision inspection into a single, highly compact device. By bundling multiple capabilities in one, the V/F400 and V/F300 Series lower hardware costs and minimize the work required for commissioning and maintenance. Read more:Related Products

-

Faster machine operation, cameras for every application

-

High-speed, high-accuracy inspection and measurement

-

MS-3 Compact Laser Barcode Scanner

-

QX-830 Industrial Barcode Scanner

-

QX-870 Industrial Raster Laser Scanner

-

MicroHAWK V320-F Multicode Reader

-

MicroHAWK V330-F Multicode Reader

-

High Resolution Handheld Barcode Reader

-

MicroHAWK V420-F Autofocus Multicode Reader

-

V430-F Industrial Ethernet Barcode Reader

-

3 in 1 RFID system: Antenna, Amplifier & Controller in a single compact housing

-

UHF RFID System

See also our other Key Applications & Solutions

Laser Marking

Laser marking provides the most durable marks and easy to read codes to guarantee that parts can be identified throughout the life cycle of the product.

Code Quality Verification

The quality of the code is the key process parameter to guarantee a reliable traceability system. You want to be able to read 100% of the traceability codes, 100% of the time.

Communication & Implementation

Traceability is all about reliable data collection at all stages of manufacturing, without impacting production efficiency. The challenge is to realize reliable data collection with limited implementation costs.