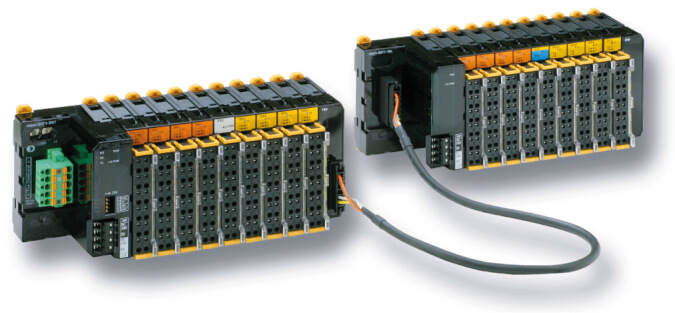

SmartSlice

The smartest modular I/O system

Omron's SmartSlice I/O system is compact, intelligent and easy. When used with Omron's CS1/CJ1 DeviceNet master units it is plug-and-work, no configuration tool is required. By using built-in functions such as pre-scaling, totalising, differentiation and alarming in analog I/O units, PLC programming can be minimised. Preventive maintenance data can be accessed using CX-Integrator software, standard PLC function blocks or NS-series Smart Active Parts.

- Most compact in the market (84 mm high)

- Easy set-up, backup and restore functions

- Diagnostics and preventive maintenance data at I/O level

- Detachable terminal blocks allow hot-swapping without re-wiring

- 3-wire connection with 'push-in' technology, no screwdriver required for installation

Specifications & ordering info

| Product | Type of module | Digital input type | Digital output type | Connection method | Number of digital inputs | Number of digital outputs | Number of encoder input channels | Permitted voltage at input | Output current | Short-circuit protected outputs | Max. encoder input frequency | Number of IOV (V+) terminals | Number of IOG (V-) terminals | Communication port(s) | Description | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

Positioning | Incremental encoder, Line driver (RS-422), PNP | PNP | 1 | 100 kHz | 1 | 2 | SmartSlice positioning unit, 1 x encoder input (A/B/Z), 100 kHz, 24 VDC PNP / RS422 line driver inputs, 1 x 24 VDC PNP control input, 2 x PNP 0.5 A range control outputs |

|

|||||||

|

|

Bus coupler | EtherCAT Slave | SmartSlice communication adaptor for EtherCAT, connects up to 64 GRT1 I/O units (End plate to be ordered separately) |

|

||||||||||||

|

|

Digital I/O | PNP | None | 1-wire, 2-wire | 8 | 0 | 15-26.4 V | 0 A | No | 4 | 0 | SmartSlice 8 x digital inputs, 24 VDC, PNP |

|

|||

|

|

Digital I/O | None | PNP | 2-wire, 3-wire | 0 | 4 | 0.5 A | Yes | 4 | 4 | SmartSlice 4 x digital outputs 0.5 A, 24 VDC, PNP, with overcurrent and short-circuit protection |

|

||||

|

|

Digital I/O | None | PNP | 1-wire, 2-wire | 0 | 8 | 0.5 A | No | 0 | 4 | SmartSlice 8 x digital outputs 0.5 A, 24 VDC, PNP |

|

||||

|

|

Digital I/O | None | PNP | 1-wire, 2-wire | 0 | 8 | 0.5 A | Yes | 0 | 4 | SmartSlice 8 x digital outputs 0.5 A, 24 VDC, PNP, with overcurrent and short-circuit protection |

|

Accessories

Ethernet cables and accessories

EtherCAT patch cables, improved shield

Note: For [.] fill in the 1-character length code.

Ethernet patch cables, standard RJ45 connectors

Note: For [...] fill in the length in cm.

Ethernet patch cables, RJ45/M12 connectors

Note: For [.] fill in the 1-character length code.

Specifications

Accessories

Ethernet cables and accessories

Accessories

Industrial switching hubs

|

EtherNet/IP control data priority

Broadcast storm and LSI error detection |

|||||

EtherCAT junction slave

Need assistance?

We’re here to help! Reach out, and our specialists will assist you in finding the best solution for your business.

Contact me SmartSlice

Thank you for submitting your request. We will come back to you as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadQuotation for SmartSlice

By completing this form you can request a quotation. Your personal details will be handled confidentially.

Thank you for requesting a quotation. We will provide you with the required information as soon as possible.

We are experiencing technical difficulties. Your form submission has not been successful. Please accept our apologies and try again later. Details: [details]

DownloadFeatures

Modular intelligence

Smartslice is the most intelligent and easy-to-use remote I/O system currently available. It allows you to:

- Minimize engineering time

- Troubleshoot rapidly

- Schedule maintenance to prevent breakdowns

Network

Transparent communication

Open for communication by open standards

- PROFINET IO: Built-in Ethernet switch and MRP ring redundancy.

- PROFIBUS DP: FDT-DTM for easy access to all intelligence in SmartSlice.

- DeviceNet: The industrial CAN protocol. Efficient and Robust.

- CompoNet: Plug-and-work. No setup required.

- MECHATROLINK-II: For integration in motion control systems.

- EtherCAT: For Trajexia and Sysmac controllers.

Hot swap

No need to stop

Reliable 3-piece construction enabling you to swap modules during operation, without rewiring. All I/O unit data can be backed up in the bus interface unit at the flick of a switch. Recovery is even simpler; after hot-swapping a unit, all settings are automatically loaded.

Tool-less

No tools required

Easy push in wiring for quick installation. The SmartSlice terminal blocks provide fast and reliable screwless clamp connections.

Smart features

All Omron I/O units have built-in Smart Features that help to:

- Reduce engineering time

- Plan preventative maintainance

- Increase your productivity

Calendar

Smart I/O can store the last date on which you performed maintenance. A better overview will help you plan maintenance more efficiently.

Counter

Smart I/O units all keep track of duration and number of operations, to help you plan machine maintenance. Timely warnings to inspect and adjust the machine will minimise unplanned downtime.

Volt meter

Smart I/O monitors its own supply voltage, and will warn you if the voltage is out of safe range - e.g. due to damaged cable or poor connection.

Stopwatch

Smart I/O can measure delays between two I/O signals with millisecond accuracy. When your preset limit is exceeded, Smart I/O will warn you that wear or lack of lubrication has reduced machine performance.

Calculator

Smart Analog I/O performs data pre-processing to help you reduce PLC programming. Scaling and alarms, and even totalising or rate-of-change calculations are handled inside the unit.

_instruction_sheet_en.jpg)

_instruction_sheet_en.jpg)