Customer References

Explore how our industrial automation solutions have helped our customers solve challenges and improve productivity, safety and efficiency. Leading the way to the factory of the future where humans and machines work side-by-side in harmony

Teklas enhances intralogistics efficiency with Peak Porter and OMRON Mobile Robots

09 July, 2024 Teklas, a global leader in fluid management systems, operates 12 factories across 6 countries, continually advancing its position in the automotive industry. Teklas specializes in advanced thermal and fluid management solutions for the automotive industry. Their offerings include systems for fluid circulation, thermal management, and air conditioning, serving major automotive manufacturers globally. With a clear focus on operational efficiency, Teklas has taken significant steps in modernizing its intralogistics through collaboration with Peak Porter. Peak Porter specializes in automated intralogistics solutions for internal logistics processes, optimizing storage, transport, and handling operations. This collaboration has allowed Teklas to automate its storage processes, using autonomous mobile robots (AMRs) from OMRON. By integrating these technologies, Teklas has successfully improved the sustainability and efficiency of its facilities.By opting for robotic technologies in production and storage processes, Teklas has succeeded in minimizing errors and reducing manual labour. As a result, disruptions and issues in operations have been largely eliminated. The company is also extremely satisfied with the results obtained from the integration of automatic intralogistics systems provided by Peak Porter.

Automated Solution for Case Erector Loading: Coboloader from Inser Robótica

14 June, 2024 Improving the end-of-line efficiency and ergonomics with a collaborative robotic cell

Streamlining order fulfilment in logistics operations: Distributor of electrical motors puts a mobile robot into action

31 May, 2024 Brd. Klee A/S, a Danish distributor of electrical motors, partnered with Ølgod Elektro to implement an autonomous mobile robot (AMR) solution from OMRON, aiming to optimize their logistics processes. By integrating the OMRON LD250 mobile robot, Brd. Klee significantly increased productivity, enhanced flexibility, and improved workplace safety. The solution streamlined order fulfilment, reduced manual labour, and ensured a smoother internal goods flow. With seamless integration and collaboration, Brd. Klee achieved operational excellence, setting the stage for future development and innovation.

Manufacturing excellence meets automation expertise:

29 May, 2024 HB-Maschinenbau relies on technology from OMRON

Watch video on an innovative anti-sloshing solution for soup and ready meal packaging

25 April, 2024 Argo offers a significant increase in productivity by 30-40%, ensuring high seal quality and hygiene standards. With reduced machine contamination and minimized tray waste, it contributes to sustainability efforts. Italian Pack's customizable solutions, coupled with OMRON's technical expertise, enable access to new customer segments with high standards, strengthening their market position. Argo represents a successful collaboration, delivering tangible benefits to manufacturers of soups, sauces, and ready meals.

Picomel looks to the future with a visionary production line

17 January, 2024 Vertical factory saves space and energy while reducing waste

Empowering operators, enhancing efficiency:

14 November, 2023 Sanofi automates palletizing with collaborative robots

SolarEdge e-Mobility transforms production processes

13 October, 2023 FasThink solution streamlined warehouse operations with autonomous mobile robots

Ricciarelli ensures the perfect closure of spaghetti packaging

28 August, 2023 The new horizontal cartoning machine for long pasta utilizes OMRON's vision systems to verify the effective closure of the packaging and perfect OCR/OCV marking.

Enhancing safety and efficiency:

23 August, 2023 OMRON's new M1 inverter transforms tile manufacturing

Laser Quality Markings automates repetitive machine tending

03 August, 2023 Moving from manual labour to collaborative automation frees up operators for creative work

Mobile robots streamline internal logistics at HIPRA

13 July, 2023 Autonomous mobile robots increase the flexibility, efficiency, and productivity of material transport.

ŠKODA AUTO uses LD mobile robot at Vrchlabí plant

17 March, 2020 The autonomous robot contributes to the continuous improvement of work safety in Vrchlabí and helps to minimise work risks. It recognises people crossing its path as well as other vehicles and stationary obstacles.

Green is key: sustainability in battery manufacturing for E-mobility

05 February, 2020 Today, sustainability is no longer a niche topic, but something that companies are integrating into their business strategies. Not only are sustainability practices necessary to answer the changing demands of consumers, the marketplace and governments, they are also increasingly being seen as a competitive strength. That’s because sustainability practices reduce energy consumption and waste, and also help companies use their resources more efficiently. They even help companies optimize their manufacturing agility and enable them to respond to fluctuating demand and the growing need for personalization. And finally, sustainability can play an important role in acquiring and retaining customers, as well in developing new market opportunities.

Agile and clever tailor-made mobile robotics

04 November, 2019 Major German automotive group optimizes efficiency and innovation leadership in material handling with Omron LD mobile robots and a conveyor attachment from cts GmbH.Automobile production and assembly line production have always been closely linked. It was not until Henry Ford began using conveyor belts in his factories in 1913 that the car was able to conquer the world as a mass-produced product. Today, a working day without assembly lines is inconceivable at the BMW factories. The group relies on innovative transport and logistics to increase efficiency and flexibility, to better link work processes, as well as to relieve employees from repetitive and time-consuming tasks. These concepts include Omron LD mobile robots for material transport that deliver a particularly high return on investment (ROI). These autonomous mobile robots are equipped with a conveyor tower - a height-adjustable load handling device, developed by system integrator cts GmbH. The interaction between employees and transport robots at BMW impressively demonstrates how factory harmony can be implemented in the factory of the future.

Campari Group improves safety worldwide with OMRON Safety

14 March, 2023 Putting people first: Campari Group improves safety worldwide with OMRON Safety Services. Empowering employees to promote safety from the ground up.

Vetipak enjoys the sweet taste of success thanks to robotics

08 November, 2022 Packaging solution with robotics integrated control ensures scalable processes and high-quality contract manufacturing in FMCG

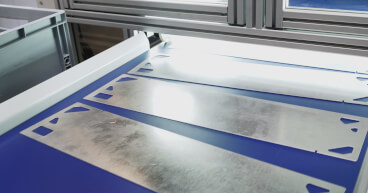

World’s first five-lane bag-in-box machine from Pro Project Machinery

08 November, 2022 New energy-efficient full servo machine boosts production by 25%

Smurfit Kappa Zedek upgrades production line with safety services

09 August, 2022 When manufacturing companies need to automate and streamline their operations, it makes sense to partner with another company that can provide a wide range of products and services. However, it’s important that the chosen partner has all the resources, technical expertise, and experience to fulfil any needs. When Smurfit Kappa Zedek, a leading producer of corrugated packaging material and high-quality displays, needed to upgrade the safety aspects of one of its key machines, it found the perfect fit with OMRON Industrial Automation.

Smurfit Kappa Zedek upgrades production line with safety services

09 August, 2022 When manufacturing companies need to automate and streamline their operations, it makes sense to partner with another company that can provide a wide range of products and services. However, it’s important that the chosen partner has all the resources, technical expertise, and experience to fulfil any needs. When Smurfit Kappa Zedek, a leading producer of corrugated packaging material and high-quality displays, needed to upgrade the safety aspects of one of its key machines, it found the perfect fit with OMRON Industrial Automation.

Myllyn Paras automates palletizing processes with a collaborative robot

15 March, 2022 Myllyn Paras, a food manufacturer based in Hyvinkää, Finland, has found an innovative way to automate its palletizing operations.

Adding data to the mix increases productivity by 8%: Cleca improves efficiency with i-BELT

23 February, 2022 Cleca, the San Martino-based company known for its sweets mix and savory dishes, chose OMRON and its new IoT data analysis service to optimize the efficiency of its ready-made broth line, which was considered insufficient to meet current demand. The upgrade, performed without installing new machinery, has enabled the Mantuan brand to produce over 800,000 cartons from the line per month.

FlexLink designs a collaborative palletiser for industrial applications

03 December, 2021 Collaborative robots (cobots) are being used in a wide variety of applications. One recent example comes from a partnership between FlexLink and OMRON. FlexLink offers flexible, modular conveyors and industrial automation equipment, including palletizing solutions, to hundreds of customers across the world. You can find FlexLink solutions on the production lines of major brands in food manufacturing and personal care. Following a request from a major manufacturer, the two companies joined forces to create a collaborative palletiser, using OMRON cobots.

Fit for the future thanks to retrofitting

12 July, 2021 Machines in food and beverage production have to be reliable, safe, fast, and maintain quality over many years and even decades.

Martini perfects the packaging of pasta with OMRON technology

29 June, 2021 Based in Italy, Martini Srl produces high-precision weighing and packaging machines for the food sector. Its new MCRS-VD packaging system enables the packaging of up to 180 packs of pasta per minute. At the heart of the solution is an OMRON NX701 1600 machine controller. This manages the movements of the MCRS-VD. OMRON’s NX-TC Perfect Sealing technology enables the end user to improve the stability of the thermoregulation involved and reduces the costs associated with the use of packaging films.

Palletising solution from Reitec meets the needs of FMCG customers

18 June, 2021 OMRON and Reitec join forces to create the new RC-1 cobot palletiser solution

Mobile robot transports waste for Kymenlaakso Central Hospital in Finland

07 April, 2021 Waste transportation and logistics planning require a lot of work in hospital environments. Waste shipment is also a physical task that places demands on both time and human resources.

Cobot Dashboard: How to visualize data for OEE improvement the smart way

16 March, 2021 The factory of the future is not only based on a well-orchestrated interaction of the most diverse machines, robots, sensors, and AI technologies. Entrepreneurs and decision-makers are also increasingly faced with the challenge of reconciling the vast amounts of data collected by the various production lines and making the best possible use of it to support their decisions. Not only does a comprehensive data strategy need to be developed. There are also technologies required that process and present the data in such a way that issues are immediately identified before major problems occur.

ControlTec helps Polish hospital tackle the pandemic with a UVC mobile robot

26 January, 2021 Using an OMRON LD mobile robot, ControlTec was one of the first companies in the world to develop a sterilisation robot equipped with a UVC irradiator.

Improved flexibility, agility and traceability with mobile robots for Normagrup

06 January, 2021 Normagrup, which specialises in technologically advanced lighting, needed to automate the transport of materials between three production areas, the assembly area and an automated warehouse. This involved moving through narrow spaces shared with factory personnel.

Mobile robot streamlines food deliveries

30 November, 2020 A whistling autonomous mobile robot has been seen recently moving around the corridors of shopping centre in Helsinki, Finland. Operated by OMRON’s solution partner Dimalog, the robot was taking part in a month-long ‘Home On-Demand’ automated courier service trial.

3 Ways COVID-19 is Impacting Logistics Operations in the UK (and what to do about it)

04 November, 2020 By Stuart Coulton, Regional Manager, OMRON UK North

High-speed robot tests the reliability of black boxes

14 May, 2020 A non-destructive alternative to crash tests