Customised Machines: Modular design in an integrated environment

Published on 02 September, 2025 in Flexible Manufacturing

How to configure and personalise machine functionality at runtime

The problem: Every machine is a new project

- Redundant engineering efforts

- Longer commissioning times

- Higher risks of errors and after-sales issues

- Increased costs and delays

The ultimate dream of a machine builder

- Based on the RFQ, dynamically configure machine functionalities with automated feasibility checks

- Instantly visualise and validate the design with the customer through simulation: "Is this what you had in mind?"

- Use a digital twin to simulate machine performance across different scenarios provided

- Automatically generate accurate quotations for labour and materials

- Directly link CAD designs to machine code generation

- Produce complete documentation packages, from manuals to maintenance schedules, without extra effort

The path forward: What machine builders are doing today

- Adopting modular design principles to allow scalable, flexible machine configurations that can evolve with customer demands

- Developing pre-engineered lines and modular systems that can be assembled on demand

- Applying modularity not just to hardware (mechanical/electrical), but to control software as well, enabling faster re-use and adaptation

Enabling the vision: OMRON helps to make it real

- One software source for machine control: A unified user-friendly interface for: PLC, motion, human-machine interface (HMI), safety, robotics control, all in one download.

- 3D simulation of the machine movements: This allows engineers to visualize machine operations in a virtual environment, ensuring accurate testing and validation before physical implementation.

- During commissioning the Sysmac platform offers one project to be able to effectively personalize machines per customer, including safety!

- Scalability: The platform can grow with the needs of the customer, accommodating new functionalities and configurations as required, or scale down and ‘downtune’ when options are not needed and a basic machine fits the requirement.

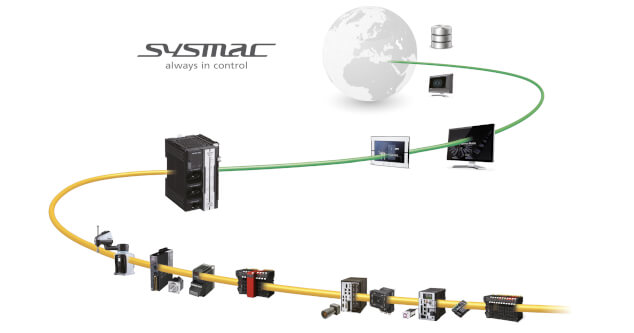

How: Streamlining development and commissioning with OMRON’s Sysmac platform

- A single software source for the entire control system

- Built-in 3D motion simulation to visualize axis movement, robot kinematics, and full sequences

- Wizard-based tools for project generation and machine setup

- Easy connection to third-party design environments like ePlan, Matlab/Simulink, Solidworks, Flowsource or AutomationML

- Configuration instead of programming – especially powerful during Factory Acceptance Testing (FAT) or Site Acceptance Testing (SAT)

EtherCAT Extended Functions: The enabler of modular machines

Modularity isn’t just a mechanical concept. It applies to control software and communication as well. OMRON’s EtherCAT Extended Functions (EEF v3) redefine how we approach the design and implementation of modular machines. They go beyond standard network communication. Automatic detection and mapping of the EtherCAT I/O and motion devices, and with that exact functionality present in the machine — plus integrity of hardware troubleshooting — facilitates scalable machine sections with plug-and-play EtherCAT nodes. As a result, it allows machine builders to maintain a single project template and configure specific machine options at runtime.Operational benefits for customers

- Customizable machines: Technology such as OMRON’s EtherCAT Extended Functions facilitates easy machine module selection, allowing for customisation without altering the underlying program.

- Simplified troubleshooting: Maintenance becomes more straightforward with user-friendly interfaces, enabling quick adjustments and updates.

- Increased flexibility: The ability to load new controller programs, even without the need for proprietary software tools, enhances operational efficiency on site.

- And with the various focused features in a single software platform, machines can be commissioned in half the time compared to traditional approaches.