Make it Excellent

Strive for operational excellence and optimize quality with our innovative automation solutions. Give your team the tools to boost productivity with seamless integration, fully committed to continuous improvement.

Ensure continuous improvement with agile production

At OMRON, we enable manufacturers like you to unlock operational excellence in production with automation.

Tap into the potential of real-time data monitoring, remote connectivity and continuous process improvement with our latest innovations. Transform your production lines with smart manufacturing technologies!

Smarter Manufacturing starts here

Expert Insights into Operational Excellence

Transforming Machine Building through Digital Enablement: Using Industrial Data and Connectivity for Next-Level Performance

Revolutionising Quality Control: AI and Data Capture Transform Manufacturing

Optimising Production: How Smart Maintenance Technologies Are Changing the Game

Unplanned downtime is sabotaging production goals. It's time to take action

Unexpected machine stoppages aren't just inconveniences—they represent costly disruptions that derail schedules, increase operational expenses, and reduce profitability. Efficiency and reliability are crucial factors for maintaining competitiveness in manufacturing, so, minimising productivity losses such as unplanned downtime must be a strategic priority for both small and medium enterprises (SMEs) and large corporations.

A meeting of minds: IT/OT convergence in industrial automation

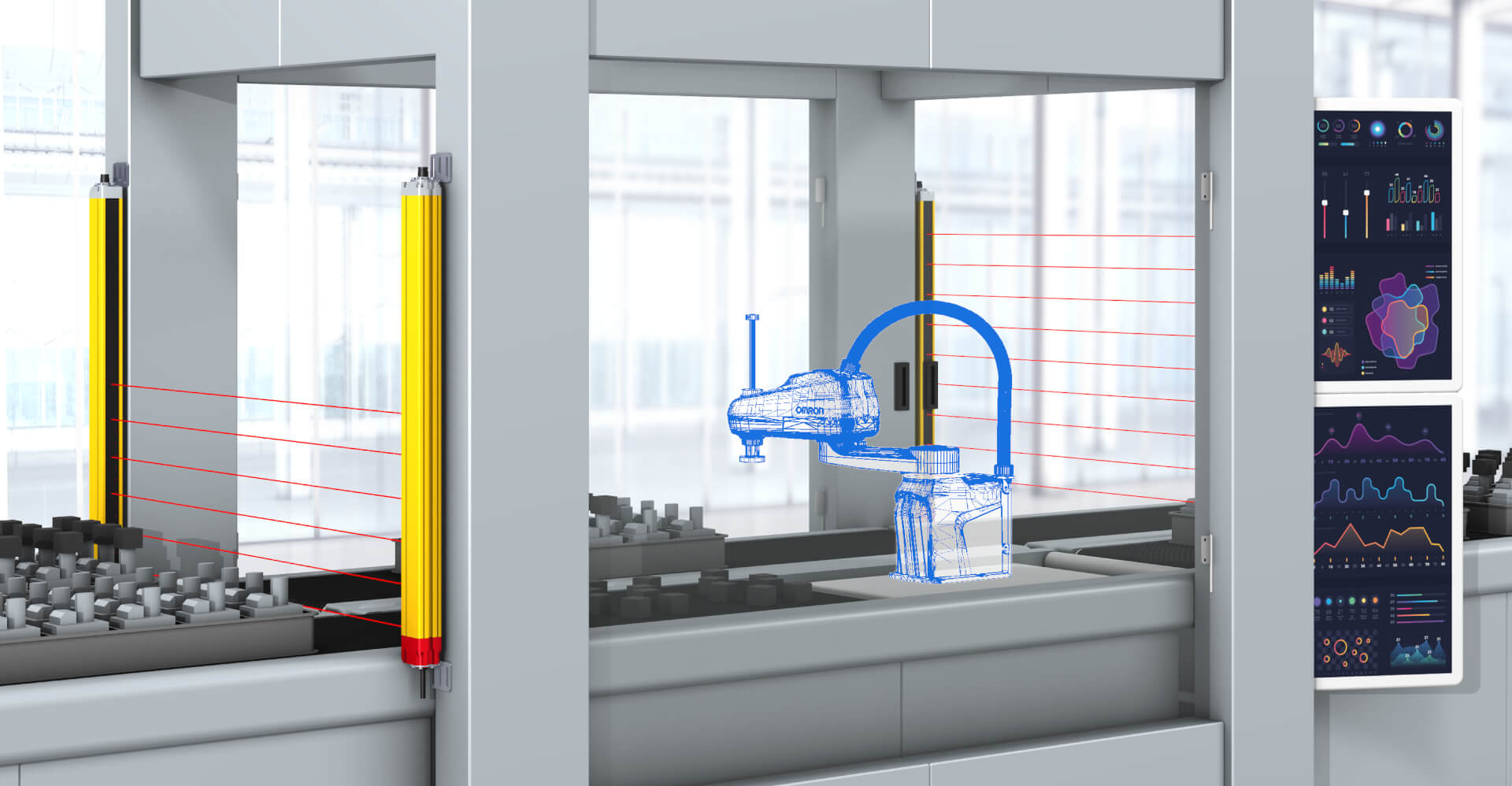

Synergistic approach to smart automation with virtual twins

Future-focused manufacturers are edging closer to their ideals of flexible, efficient and sustainable production by exploring digital transformation in earnest. However, as interest in digitalisation builds, it is becoming apparent that a huge gulf exists between the worlds of OT (Operational Technology) and IT (Information Technology). And this divide needs to be bridged if today’s visions for factories of the future are to become tomorrow’s reality.

Digitising with open standards: the recipe for a good night’s sleep

Artificial Intelligence: don’t call me stupid

Discover our customer success stories achieving operational excellence

Discover how businesses like yours are optimizing processes and driving efficiency with our lean implementation.

Manufacturing excellence meets automation expertise:

Watch a video about a complex production system for a customer in the construction sector that uses robotics and vision technology from OMRON

Adding data to the mix increases productivity by 8%: Cleca improves efficiency with i-BELT

CLECA i-BELT

Steierl-Pharma modernizes and optimizes labelling processes with inspection technology

Hardly any other industry is subject to such high-quality requirements and legal regulations as pharmaceutical companies.