Integrated Safety

One view. Total Control. Zero Compromise.

Integrated Safety

Safety and automation in one seamless system from the start

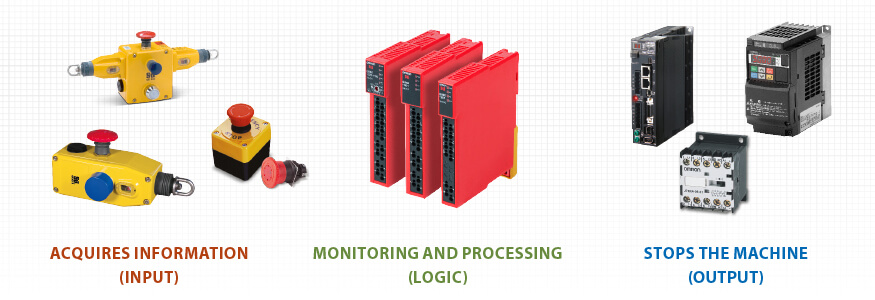

What is basic (non-integrated) safety in automation?

- Input devices (like light curtains, scanners, door interlocks, safety mats, or E-stops) detect when a person enters a hazardous area or manually trigger a stop.

- Logic devices process the signal to decide if action is needed to cut power or remove hazardous energy in the case of emergency stop circuits, or keep motion on reduced speed for protective (Safeguard)circuits.

- Output devices (like contactors or clutch brakes) then act to eliminate the hazard—either by disconnecting power or physically stopping motion.

- Input devices

- Logic Device

- Safety Logic

- Output devices

Non-Integrated Safety

Each component is a separate hardwired device (I-L-O)

- Input devices Hardwired to safety relays

- Logic Device Automation: standard PLC, Safety: separate relays

- Safety Logic Hardwired Logic

- Output devices Triggered by relays

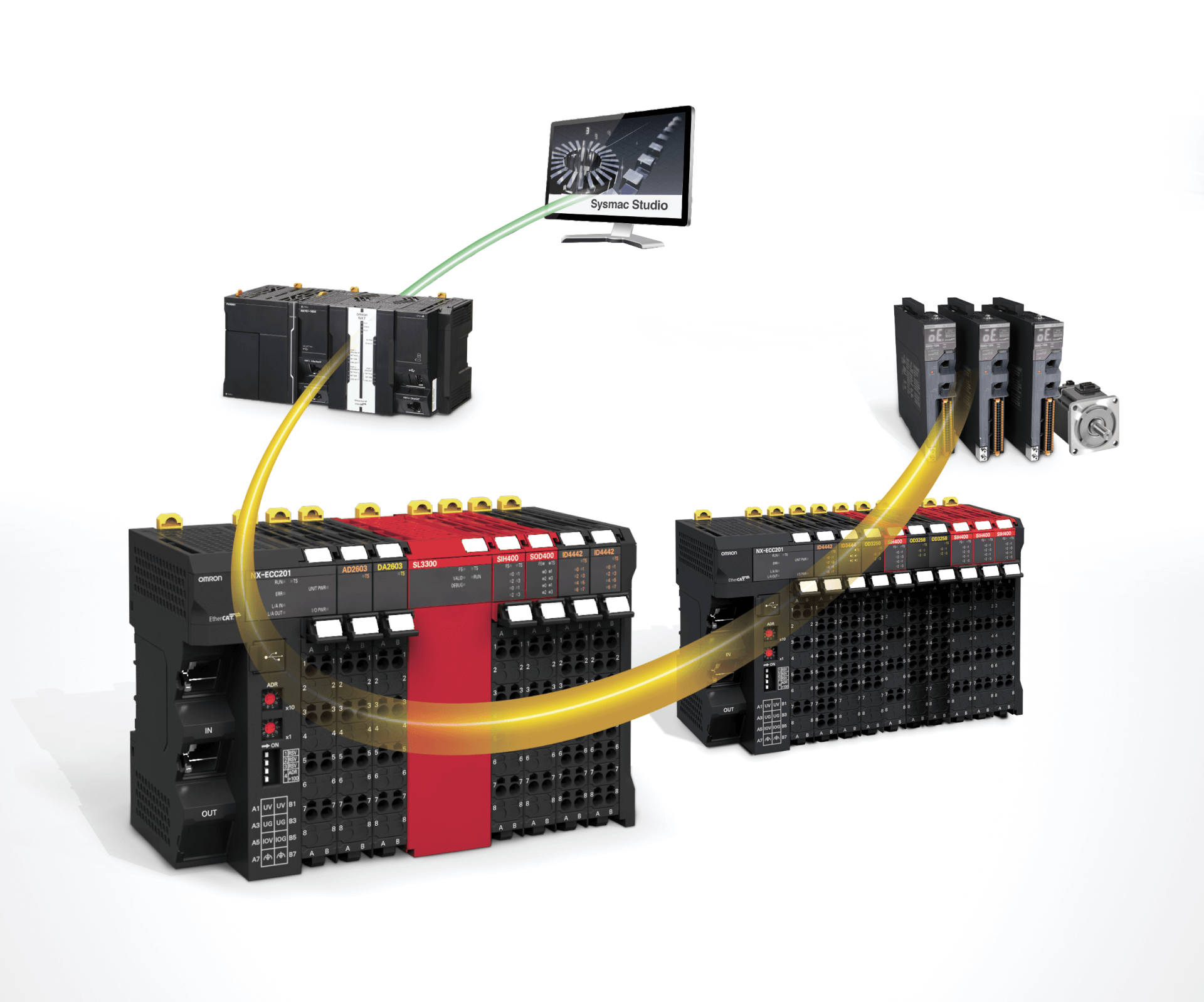

Integrated Safety

Single control architecture

- Input devices Connected to safety-rated input modules

- Logic Device One safety PLC for both Automation and Safety

- Safety Logic Software-based (e.g. function blocks)

- Output devices Controlled by safety-rated output modules

Benefits of Integrated Safety

Why choose an Integrated Safety solution?

Future-ready

Easier to scale across complex or growing machines

When to choose Integrated Safety

Integrated Safety is ideal for more complex and scalable machines with many safety I/O points or where advanced safety functions and diagnostics are needed. Systems using safety PLCs merge all safety and control signals into one intelligent controller—enabling:

- Greater flexibility and scalability

- Easier system updates and modifications

- Seamless communication between safety and standard control

- Mid and Long-term cost savings and performance gains

- Number of safety I/O points

- System complexity

- Required integration with control logic

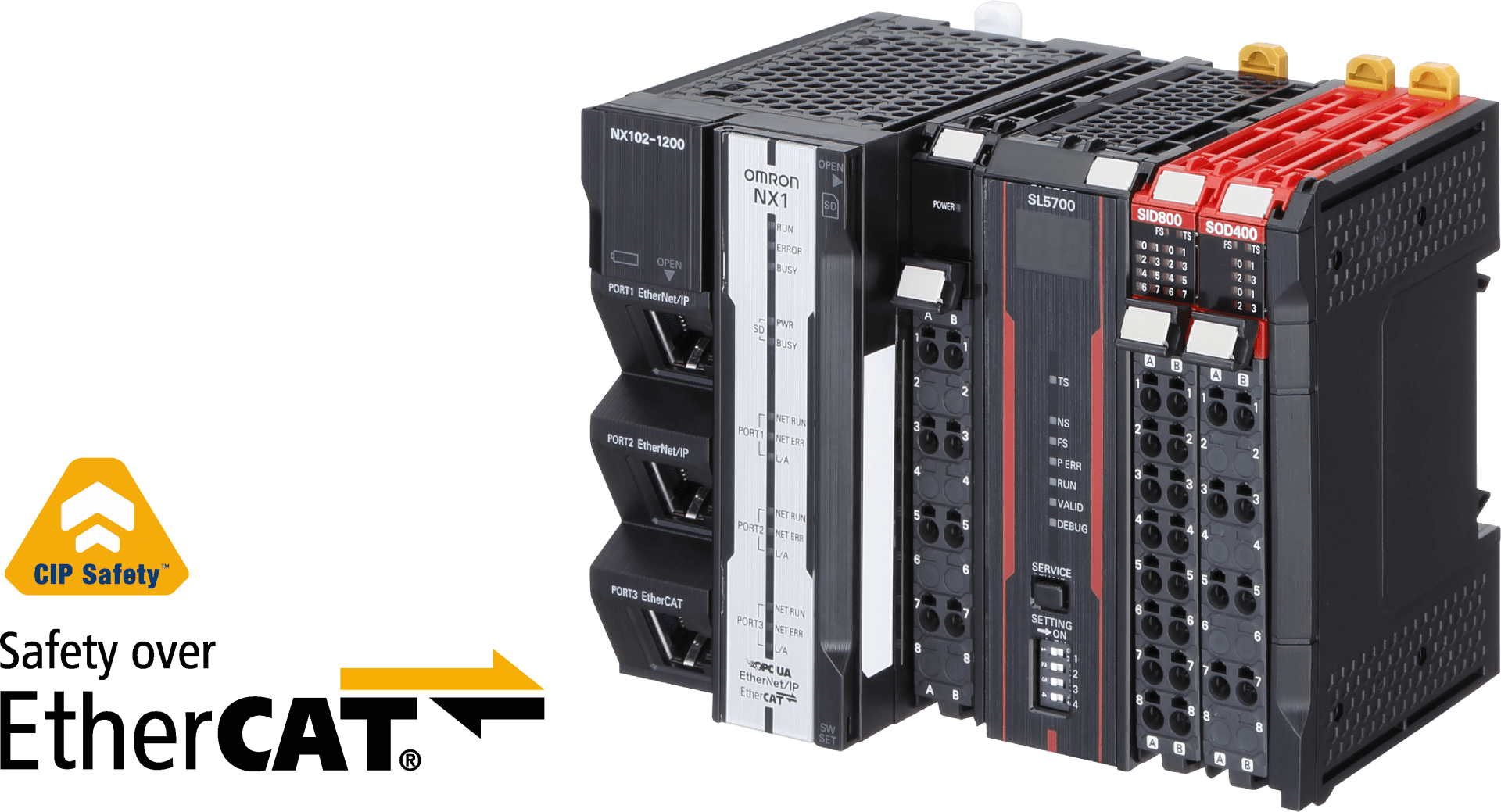

Integrated Safety requires One software for automation and safety: Sysmac Studio

Why it matters

- Less hardware, fewer errors

- Faster setup & maintenance

- Integrated safety to meet PL e / SIL 3 standards

Key Capabilities:

- Unified programming environment. Configure and program both standard and safety controllers , using ladder logic, structured text, and IEC 61131-3 compliant function blocks.

- Seamless network & I/O setup Easily build networks (e.g. EtherCAT, FSoE) and add I/O modules, including safety I/O. Drag-and-drop configuration reduces wiring complexity.

- Integrated safety programming Develop certified safety logic using pre-built function blocks for E-stops, guard doors, and more—fully integrated within the same controller and software. Full diagnostics shared anyware.

- PLCopen Safety. Sysmac Studio includes built-in function blocks and supports PLCopen Safety compatible function blocks and instructions to speed up development.

- Simulation & testing Test programs virtually before deployment to minimize commissioning time and catch issues early. This also applies to the Safety logic.

- Real-time diagnostics Monitor all devices, I/O, and safety systems live. Get instant insights for faster troubleshooting and predictive maintenance.

- System integration Combine PLCs, HMIs, vision systems, drives, and safety devices within one platform for better coordination and easier scaling.

Sysmac Studio and Safety Function Verification

- Faster compliance checks

- Fewer resources needed

- Lower verification costs

-

Online Safety Functional Test: From manual functional safety checks to guided testing

From manual functional safety checks to guided testing: Modernising safety verification. Online Safety Functional Test reduces the number of skilled personnel required during verification on site. Discover OMRON's safety portfolio:

02:14

Customer Reference

Auxpama saved 30% on safety functions programming

Auxpama, a Spanish machine builder specialising in automated bakery solutions, has significantly increased productivity by integrating safety functions with the Sysmac control platform. Since 2014, this integration has enabled Auxpama to streamline its bread-making machines, which automate seven stages of production. The unified control system has replaced the need for separate PLCs and manual programming, allowing safety functions to be programmed more quickly - up to 30% faster. This not only saves time and money for Auxpama, but also benefits its customers by minimising unnecessary production stops and simplifying machine customizations.

OMRON's Integrated Safety Portfolio: from Components to Consultancy

The NX safety series is a flexible safety I/O system that uses Fail Safe over EtherCAT (FSoE) and/or Ethernet Common Industrial Protocol (CIP-Safety). It enables easy integration of both standard and safety products on the same EtherCAT and/or CIP-Safety network, supporting up to 1024safety I/O points. The NX series can also work alone for medium-sized applications, using Ethernet/IP for communication. OMRON's safety solutions meet international safety and PLC product standards and use PLC open function blocks.

OMRON provides different safety services to give safety advice. The main goal is to prevent accidents while boosting production, improving safety, and increasing flexibility. Services usually begin with checking safety measures for diagnostic validation. We help design and implement tailored safety solutions and our safety experts offer trainings on new features. They also assist in making sure machines and systems comply with local equipment regulations.

Meet our safety specialists in our Proof of Concept Centers where you can see working safety solutions.

Read how we consulted Campari to revolutionize its global safety programs: