OMRON Manufacturing of the Netherlands, 's-Hertogenbosch

Integrating advanced automation solutions for improving productivity, traceability and quality, unlocking the full potential of on-site workers.

OMRON Manufacturing of the Netherlands (OMN), located in 's-Hertogenbosch (Den Bosch), is our main central European location for operations. It includes a factory, our European distribution center, research & development (R&D) and repair and advanced services, such as industrial data science. The factory conducts high-mix low-volume production and multi-product variable-volume production of Human Machine Interface (HMI) solutions, Industrial PCs, fixed robots as well as safety solutions for the global market. It is an assembly factory where high-quality products are efficiently produced by coordinating product design and process design activities. We strive to improve productivity and innovate quality by continuously accumulating and analyzing production line data, and by exploring ways to effectively integrate advanced automation technologies, including robotics, vision, artificial intelligence, and safety solutions.

Autonomous mobile robots allow human workers to focus on value-added tasks

Monitoring machine stability and optimizing maintenance with artificial intelligence and data science

Robotics solutions automate repetitive processes with maximum precision

Inspection and machine vision solutions ensure quality and traceability

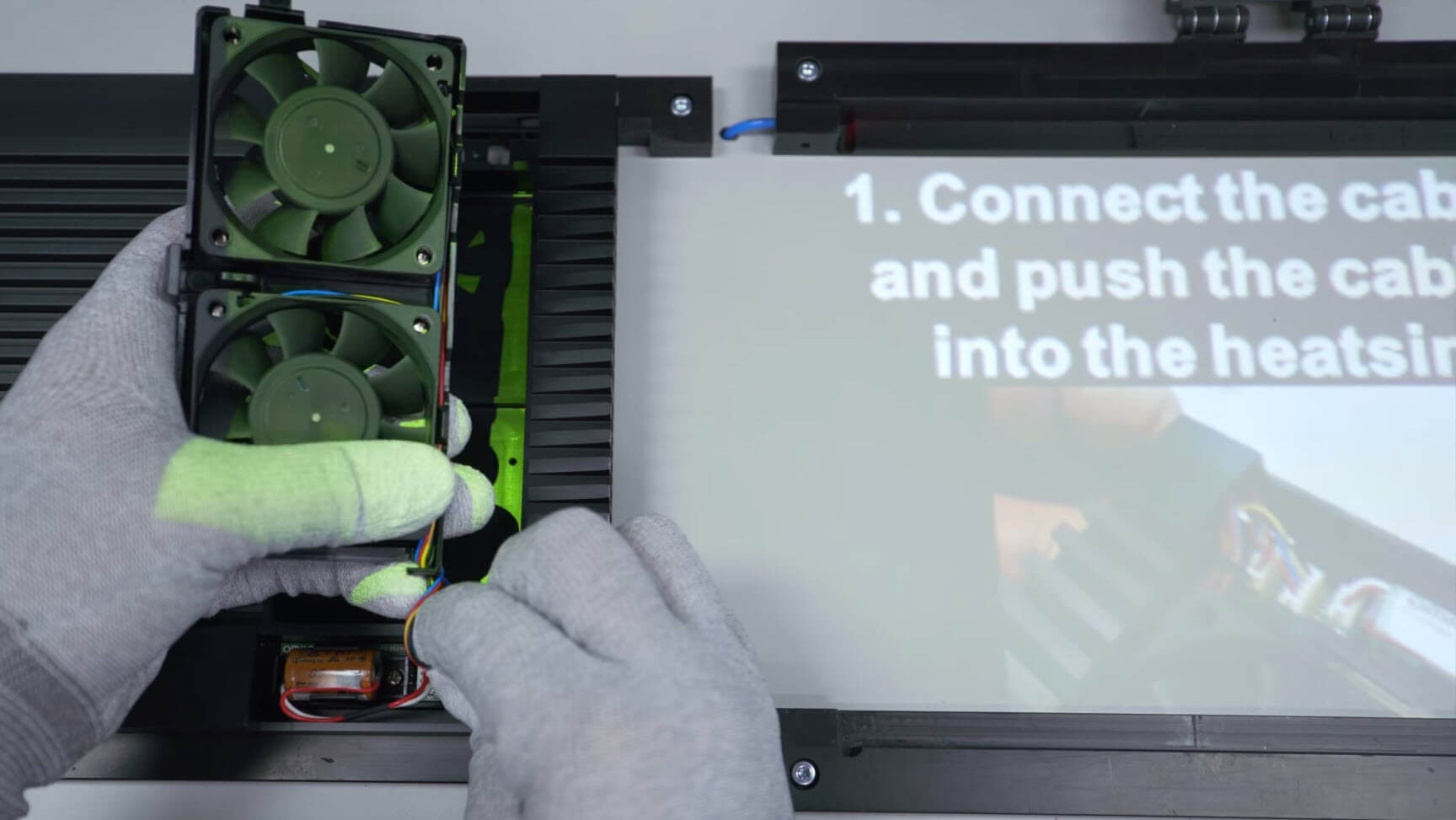

Operator guidance and assistance for high-mix low-volume production

-

How Omron Industrial PC production line is adapting I4.0 methodologies

Omron Manufacturing The Netherlands is showing how Industry 4.0 works in practice, with server-controlled line management, projected-beam operator assistance and the first steps in smart data science integration. Put all this together with strictly applied lean manufacturing, and you have a factory that demonstrated perfectly how new production methods drive higher productivity.

01:49

How Omron Industrial PC production line is adapting I4.0 methodologies

Omron Manufacturing The Netherlands is showing how Industry 4.0 works in practice, with server-controlled line management, projected-beam operator assistance and the first steps in smart data science integration. Put all this together with strictly applied lean manufacturing, and you have a factory that demonstrated perfectly how new production methods drive higher productivity.OMRON Manufacturing of the Netherlands

5234 GM 's-Hertogenbosch

Corporate customers only; reservations required in advance. For more information, please contact your OMRON sales representative.

If you are a first-time customer, please contact one of our sales offices.

Our Worldwide Production Facilities

Strategically implementing i-Automation! to create the factory of the future

Read more