Meet the RB1200 Cobot Palletiser

A revolution in end of line palletising...

RB1200 Cobot Palletiser

Designed in collaboration with our solution partner Reeco Automation, the RB1200 has the potential to revolutionise EOL palletising.

RB1200 Cobot Palletiser Introduction

-

Meet the RB1200 Cobot Palletiser

OMRON and Reeco Automation have partnered to bring you the RB1200 palletiser. A safe, flexible and versatile solution to the EOL palletising process, designed to improve production efficiency, provide enhanced flexibility and save costs. Read more:

02:18

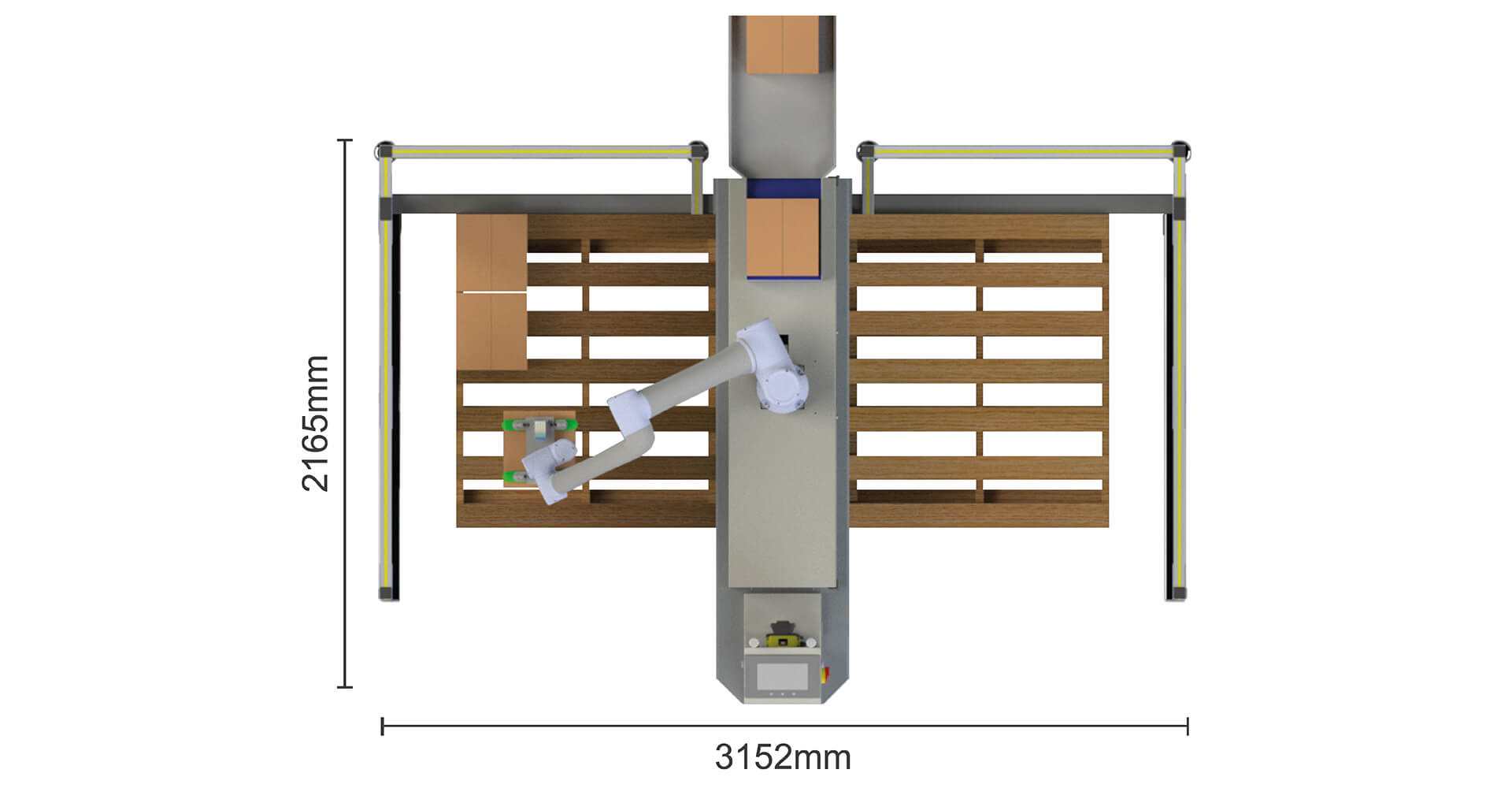

Flexible and agile solution

-

Setting up a cobot palletizer in just 5 minutes

OMRON UK and Reeco introduce the RB1200. The lack of extraneous kit makes the RB1200 easy to move between lines. The RB1200 is light and transportable; it can easily be moved by pump truck to another line within minutes. By contrast, to redeploy a traditional robot palletiser to another part of the factory would be a huge undertaking, requiring a significant logistics effort and considerable time. Read more:

00:12

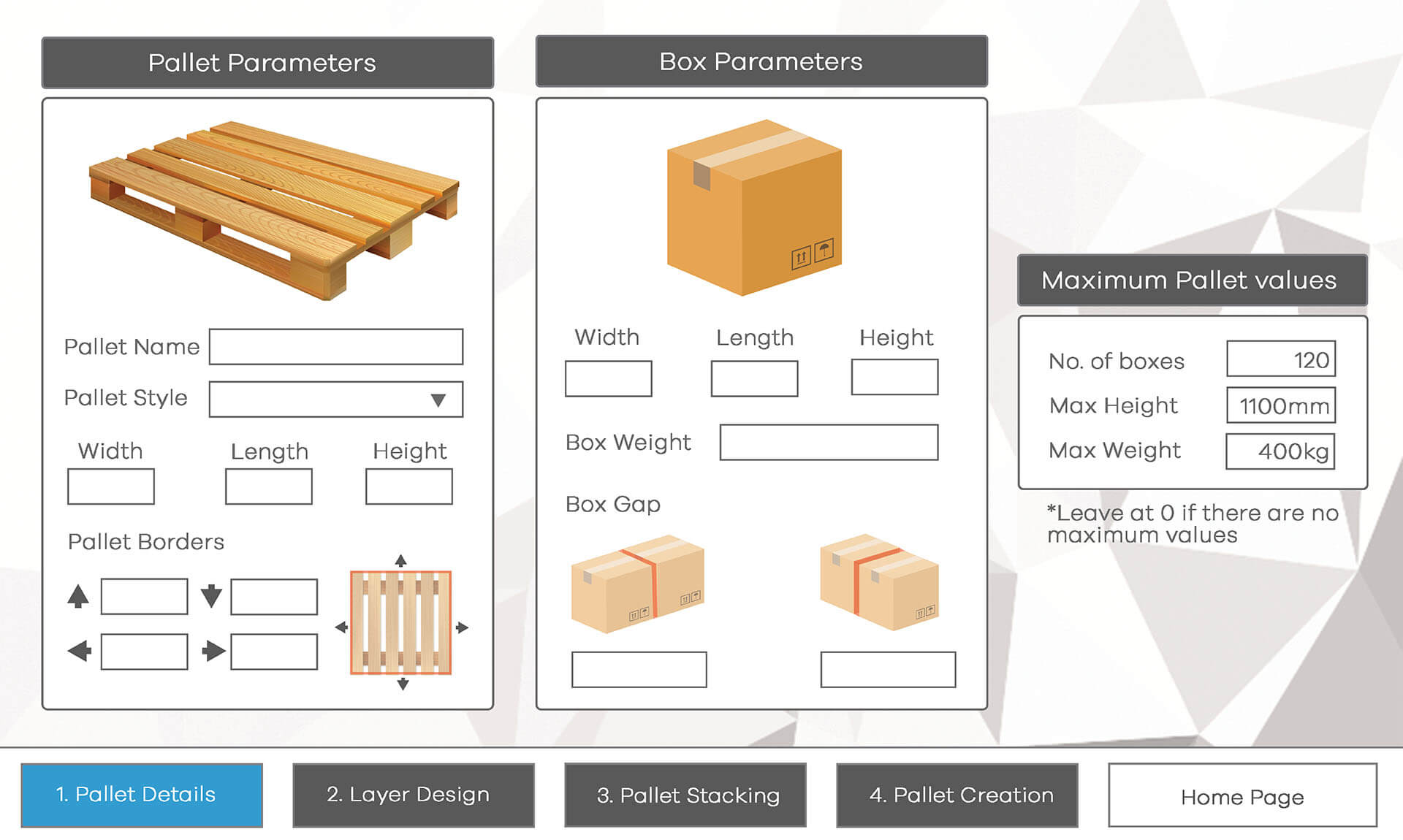

Easy Operation

Integrated Safety

Payload

Pick Rate

Flexible Box & Pallet Size

Interested in hearing more about the RB1200 Cobot Palletiser?

Fully Automate Pallet delivery and retrieval

Reeco Automation – Collaborative Robot Solution Partner

Specialising in the design, development and integration of collaborative robot solutions, REECO focuses on providing customers with turnkey automation applications that provide real value by reducing production costs, increasing efficiency and enabling flexibility by integrating around existing equipment, operators and processes. REECO’s offering continues to expand as the market continues to innovate, providing customers with advanced automation equipment, technologies and expert support through the supply of bespoke solutions and specialised automation products.